Chestnut shell-based biomass carbon material as well as preparation method and application thereof

A biomass carbon and chestnut shell technology, applied in the field of carbon materials, can solve the problems of direct incineration, for livestock use or as landfill, waste of biomass resources, environmental pollution, etc., to achieve good application prospects, improve removal rate, environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024]The present invention first provides a method for preparing a chestnut shell-based biomass carbon material, which includes:

[0025]Step 1: The chestnut shell powder and organic acid are reacted by hydrothermal method, which is specifically preferably:

[0026]Weigh the chestnut shell powder, add organic acid, place it in a polytetrafluoroethylene lining, and react in an oven. The reaction temperature is preferably 180-200°C, and the time is preferably 6-8h to obtain a hydrothermal carbon material; The organic acid is preferably selected from one or more of citric acid, salicylic acid and tartaric acid, and the concentration is preferably 0.1 mol / L to 0.3 mol / L; the mass of the chestnut shell powder (g): organic acid The volume mL is preferably (5-8): 70; prior to use of the chestnut shell powder, the waste chestnut shells are preferably washed 4-6 times with distilled water, crushed, and dried in a constant temperature drying oven.

[0027]Step 2: Place the hydrothermal carbon materia...

Embodiment 1

[0036]1) Wash the discarded chestnut shells with distilled water for 4-6 times, crush them, dry them in a constant temperature drying oven at 100°C, and store them for later use.

[0037]2) Weigh 6g of chestnut shell powder, add 70mL, 0.1mol / L salicylic acid solution, place it in a polytetrafluoroethylene liner, and react in an oven at 180°C for 6 hours to obtain a hydrothermal carbon material;

[0038]3) Place the material obtained in step 2) in a 3mol / L sodium carbonate solution, fully stir and then stand still, filter and freeze-dry for 36 hours to obtain a dried carbon material;

[0039]4) The freeze-dried sample is calcined in an inert atmosphere at a heating rate of 5°C / min to 350°C for 1 hour, then at a heating rate of 5°C / min to 800°C, and constant heat treatment for 2 hours to obtain the pre-product.

[0040]5) Use 1mol / L HNO for the pre-product3Soak, and then wash with water to neutrality to obtain chestnut shell-based biomass carbon material.

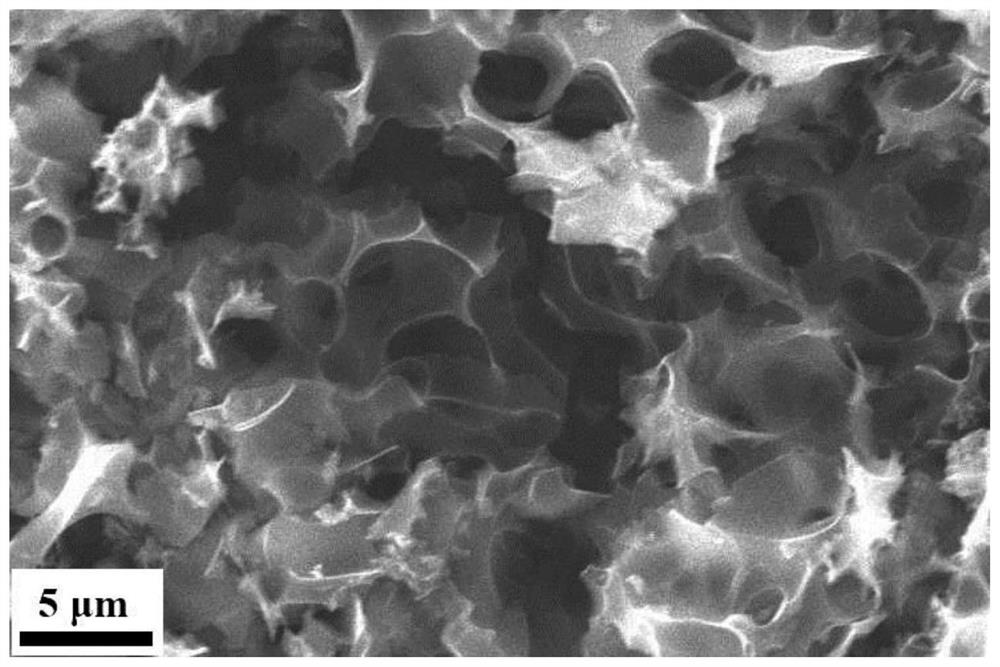

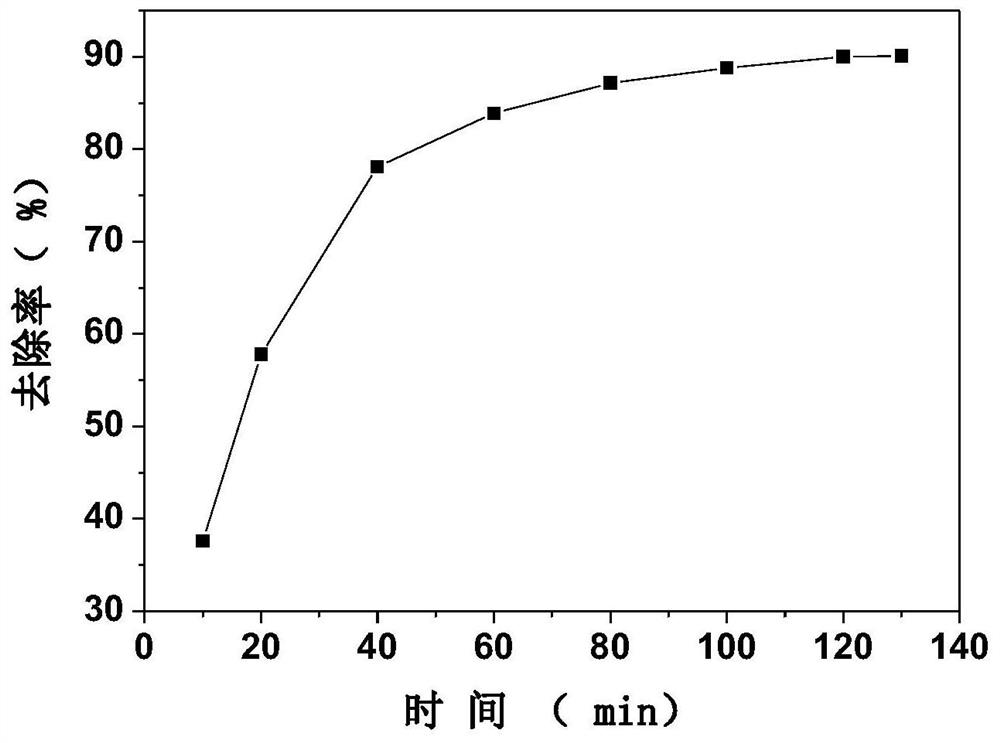

[0041]The obtained chestnut shell-based bi...

Embodiment 2

[0043]1) Wash the discarded chestnut shells with distilled water for 4-6 times, crush them, dry them in a constant temperature drying oven at 100°C, and store them for later use.

[0044]2) Weigh 7.5g of chestnut shell powder, add 70mL, 0.1mol / L citric acid solution, place it in a polytetrafluoroethylene lining, and react in an oven at 200°C for 6 hours to obtain a hydrothermal carbon material;

[0045]3) Place the material obtained in step 2) in a 4mol / L potassium hydroxide solution, fully stir and then stand still, filter and freeze-dry for 48 hours to obtain a dried carbon material;

[0046]4) The freeze-dried sample is calcined in an inert atmosphere at a heating rate of 5°C / min to 350°C for 1 hour, and then at a heating rate of 5°C / min to 700°C, and constant heat treatment for 2 hours to obtain the pre-product.

[0047]5) Soak the pre-product with 1 mol / L HCl, and then wash it with water to neutrality to obtain a chestnut shell-based biomass carbon material.

[0048]The obtained SEM image of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com