Ternary single crystal positive electrode material as well as preparation method and application thereof

A technology of positive electrode material and single crystal material, which is applied in the field of ternary single crystal positive electrode material and its preparation, can solve the problems of increasing the contact area between the material and the electrolyte, aggravating the side reaction of the electrolyte, and breaking the secondary particles, etc. Processability and cycle stability, effect of reducing surface transfer resistance, improving surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

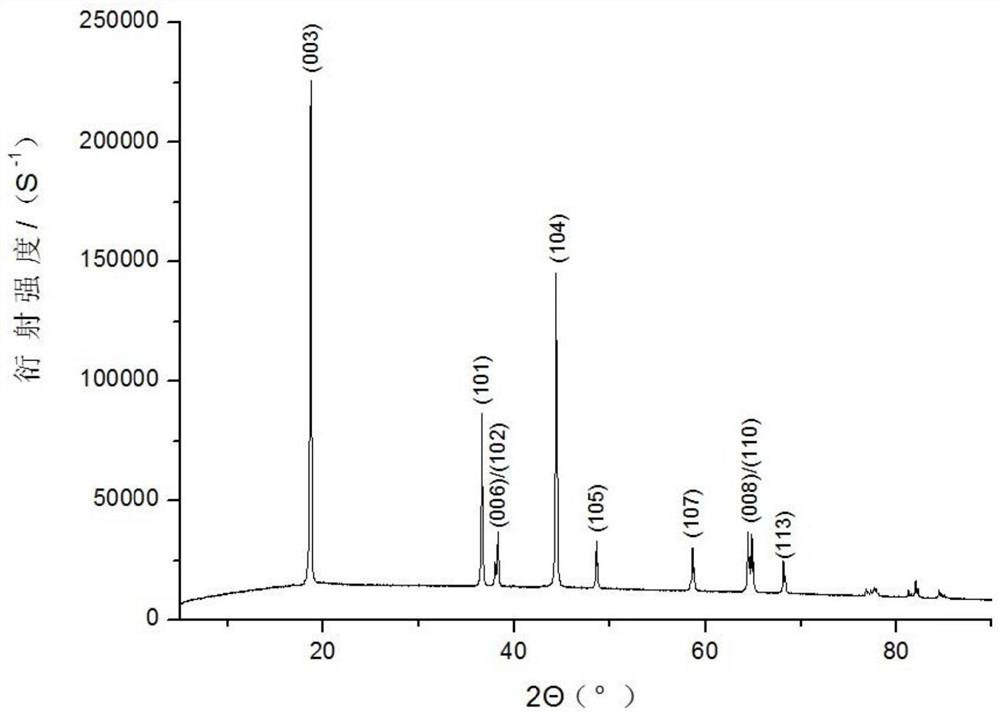

[0050] A kind of ternary single crystal cathode material, its chemical formula is LiNi 0.8 co 0.1 mn 0.1 BO 2 .

[0051] A method for preparing a ternary single crystal cathode material, comprising the following steps:

[0052] (1) The ternary polycrystalline micro-powder is mixed for 1 hour with a coulter to obtain the micro-powder raw material, and the micro-powder raw material is put into a box furnace, under the condition that the oxygen pressure of 0.2 MPa and the volume concentration of the oxygen atmosphere are 50-99.9% , the heating rate is 3°C / min, the temperature is raised to 820°C, a sintering is carried out, the temperature is kept for 12 hours, the temperature is lowered to 500°C, the cooling rate is 2°C / min, and the intermediate is naturally cooled to room temperature;

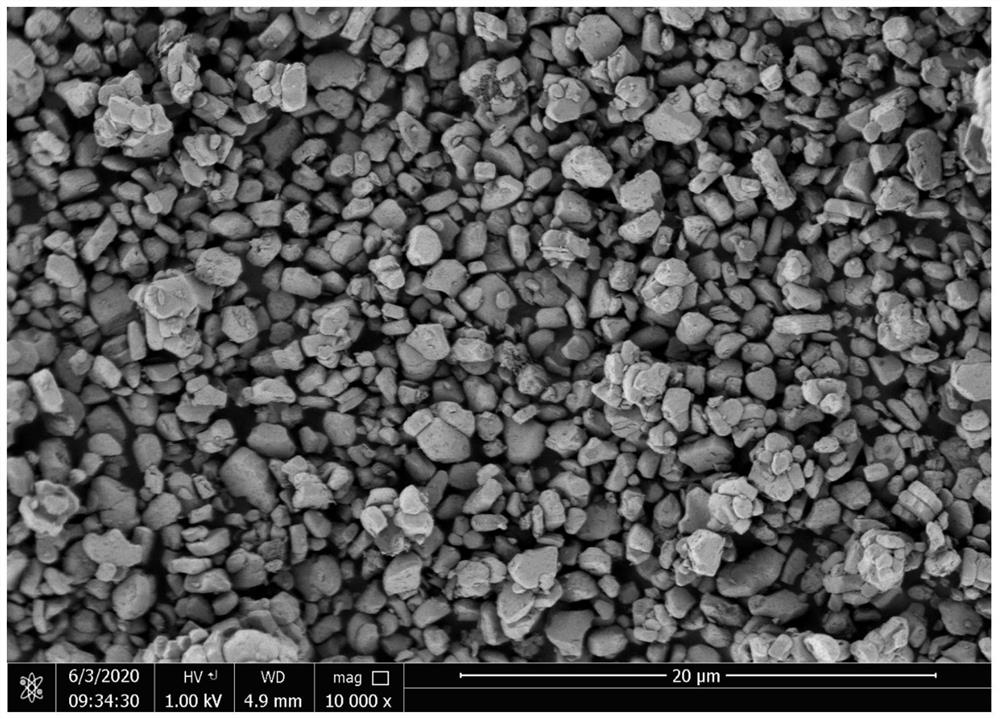

[0053] (2) The intermediate is pulverized by a fluidized bed jet mill to obtain a single crystal material with a particle size distribution of D50=2.6-3.4 μm and D99<10.0 μm, and the single c...

Embodiment 2

[0057] A kind of ternary single crystal cathode material, its chemical formula is LiNi 0.8 co 0.1 mn 0.1 BO 2 .

[0058] A method for preparing a ternary single crystal cathode material, comprising the following steps:

[0059] (1) Mix the ternary polycrystalline micropowder with a coulter for 1 hour to obtain the micropowder raw material, put the micropowder raw material into a box furnace, and under the air pressure of 0.2MPa, the heating rate is 3°C / min, and the temperature is raised to 820°C , carry out one sintering, keep warm for 12h, cool down to 500°C, the cooling rate is 2°C / min, and naturally cool to room temperature to obtain the intermediate;

[0060] (2) The intermediate is pulverized by a fluidized bed jet mill to obtain a single crystal material with a particle size distribution of D50=2.6-3.4 μm and D99<10.0 μm, and the single crystal material is washed with water and centrifugally dried. The mass ratio of pure water to material The ratio is 2.0:1, the was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com