Method for rapidly synthesizing poly (butylene succinate) or copolymer thereof

The technology of polybutylene succinate and copolymer, which is applied in the field of polymer synthesis, can solve the problems of many by-products of small molecules, long reaction time and high investment in the early stage of the device, so as to improve the efficiency of polymerization reaction, High-efficiency catalytic effect and less catalyst dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

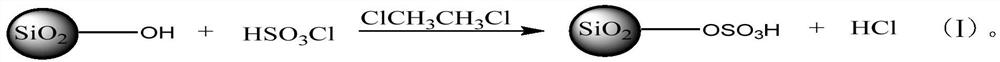

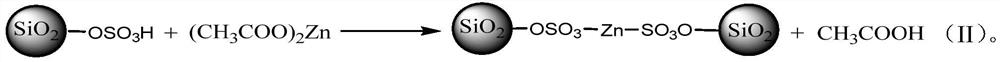

[0031] Embodiment 1. Catalyst preparation:

[0032] Add 30g of solid nano-silica and 800ml of 1,2-dichloroethane into a three-necked flask, then slowly add 17.3g of chlorosulfonic acid dropwise at room temperature, and the dropwise addition is completed within half an hour, and then the reaction system Vigorously stir for one hour, and react at room temperature for 36 hours. After almost no hydrogen chloride gas is detected, 1,2-dichloroethane is removed by a rotary evaporator to obtain an off-white solid powder. The mass after drying is 43.5g, which is stored in Standby as catalyst A in the desiccator.

Embodiment 2

[0033] The preparation of embodiment 2.PBS

[0034] In the 1000ml flask, add succinic acid 360g, add butanediol 340g, add the catalyst A0.75g that embodiment 1 prepares. Turn on the power of the microwave reactor to 300w, raise the temperature to 220°C, react for 20 minutes, and the reaction ends. The carboxyl group content at the detection terminal is 210mol / t. After the esterification reaction is completed, the polymerization reaction is started, and the polymerization catalyst tetrabutyl titanate 1.5g, the auxiliary agent B zinc acetate 0.2g, the power of the microwave reactor is 450w, the temperature is raised to 240°C, and the pressure is 100 ~200pa, reaction time 2h, get PBS product, number average molecular weight 10×10 4 , dispersibility 2.2, weight average molecular weight 22×10 4 , the product color is white.

Embodiment 3

[0035] The preparation of embodiment 3.PBS

[0036] In the 1000ml flask, add succinic acid 360g, add butanediol 340g, add the catalyst A1.0g that embodiment 1 prepares. Turn on the power of the microwave reactor to 300w, raise the temperature to 220°C, react for 30 minutes, and the reaction ends. The carboxyl group content at the detection terminal is 110mol / t. The esterification reaction is completed, and the polymerization reaction is started. Add 1.5g of the polymerization catalyst tetrabutyl titanate, 0.3g of the auxiliary agent B zinc acetate, and the power of the microwave reactor is 450w. The temperature is raised to 240°C and the pressure is 100 ~200pa, reaction time 3h, get PBS product, number average molecular weight 12×10 4 , dispersibility 2.2, weight average molecular weight 26.4×10 4 , the product color is white.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com