Preparation method of p-cymene

A technology for cymene and catalyst, applied in the field of deep processing of rosin, can solve the problems of expensive catalyst, product yield needs to be improved, catalyst preparation is complicated, etc., and achieves the effects of low price, wide use and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

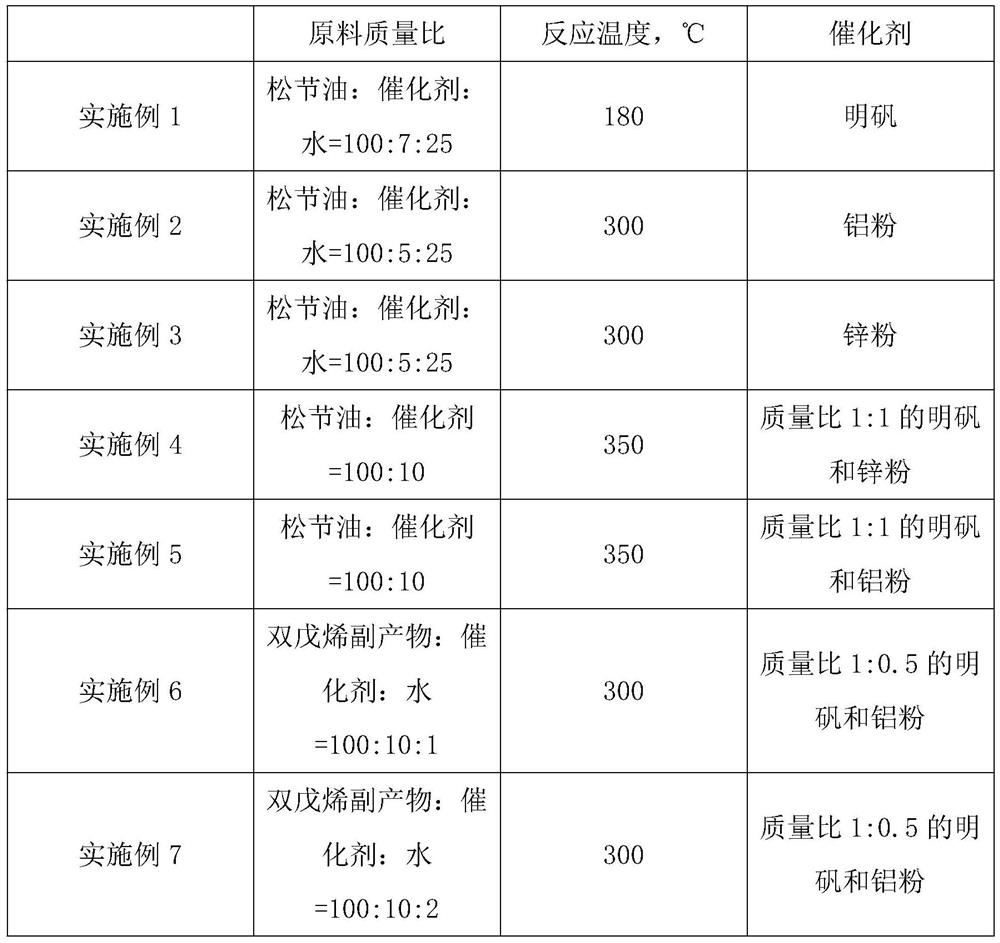

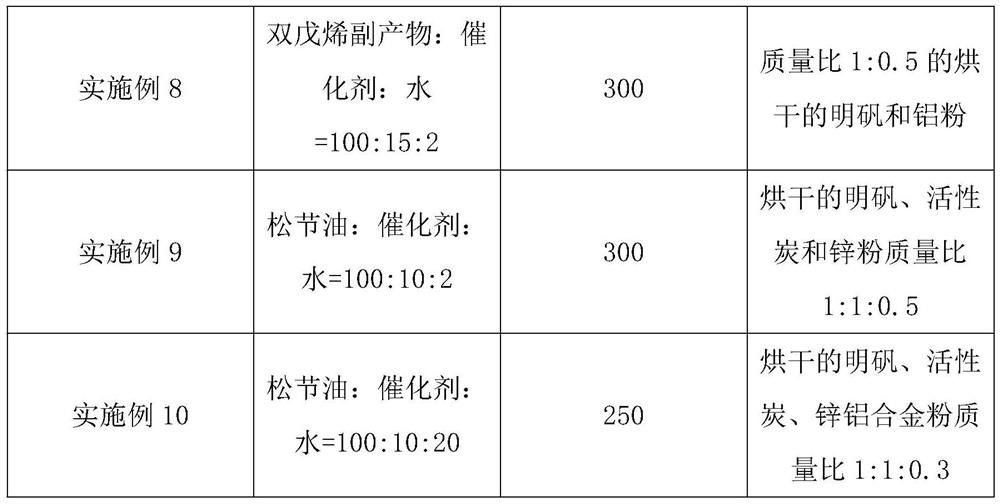

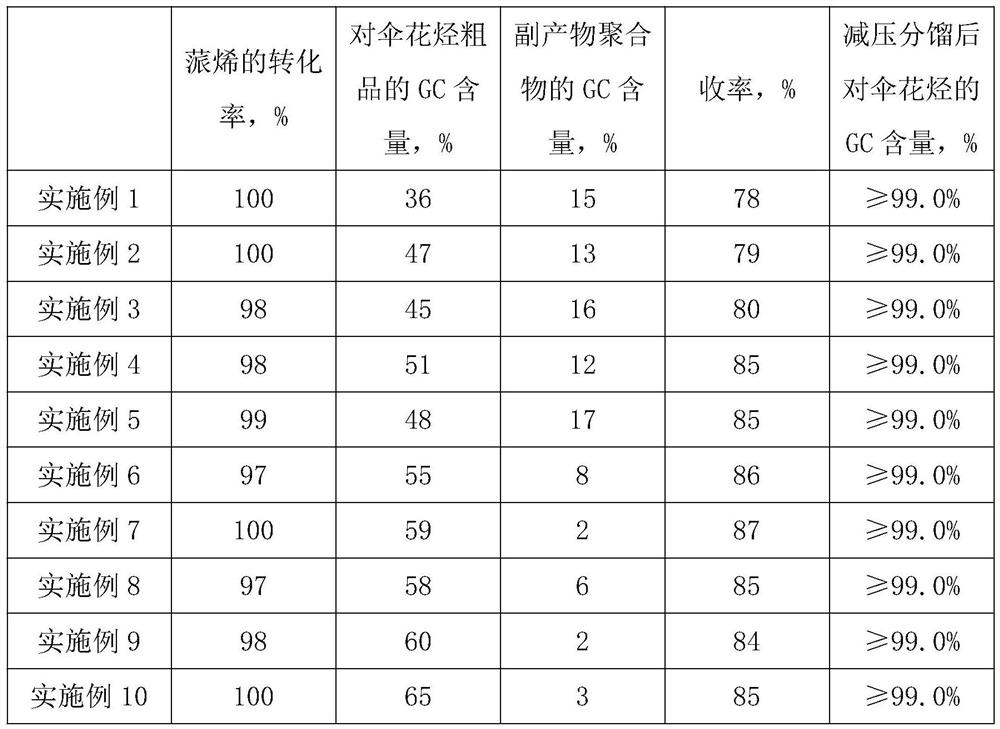

Examples

Embodiment 1

[0045] (1) turpentine (80%), catalyst and water are added in the reactor in a ratio of 100:7:25 by mass ratio, and the stirring is started at a stirring speed of 500 rpm. The controlled reaction temperature is 180° C., and the reaction time is 2 hours; The catalyst is alum;

[0046] (2) After the reaction is finished, the product is filtered to obtain a filtrate and a filter cake, and the filter cake is washed with ethanol to remove the residual product, and dried at 150° C. for reuse;

[0047] (3) adding the above-mentioned filtrate in the washing tank, adding water and washing for 2 times to obtain the crude product containing p-cymene;

[0048] (4) the above-mentioned crude product containing p-cymene is subjected to vacuum fractionation to obtain 3-pairs of Alkenes by-products and p-cymene products.

[0049] The fractionation described in step (4) is vacuum fractionation, and concrete operation is as follows:

[0050] S1: First discharge the air in the rectification to...

Embodiment 2

[0057] (1) turpentine (80%), catalyst and water are added in the reactor in a ratio of 100:5:25 by mass ratio, and stirring is started at a stirring speed of 400rpm. The controlled reaction temperature is 300°C and the reaction time is 2h; Said catalyst is 100 purpose aluminum powder;

[0058] (2) After the reaction is finished, the product is filtered to obtain a filtrate and a filter cake, and the filter cake is washed with ethanol to remove the residual product, and dried at 150° C. for reuse;

[0059] (3) The above-mentioned filtrate is added in the washing tank, and water is added to wash 3 times to obtain the crude product containing p-cymene;

[0060] (4) the above-mentioned crude product containing p-cymene is subjected to vacuum fractionation to obtain 3-pairs of Alkenes by-products and p-cymene products.

[0061] The fractionation described in step (4) is vacuum fractionation, and concrete operation is as follows:

[0062] S1: First discharge the air in the recti...

Embodiment 3

[0069](1) Add turpentine (80%), catalyst and water into the reactor in a mass ratio of 100:5:25, start stirring, stirring speed 500rpm, control the reaction temperature to 300°C, pressure 7-8MPa, react The time is 1-2h; the catalyst is 100 mesh zinc powder;

[0070] (2) After the reaction is finished, the product is filtered to obtain a filtrate and a filter cake, and the filter cake is washed with organic solvents such as ethanol, ethyl acetate, hexane to remove residual products, and dried at 200° C. for reuse;

[0071] (3) The above-mentioned filtrate is added in the washing tank, and water is added to wash 3 times to obtain the crude product containing p-cymene;

[0072] (4) the above-mentioned crude product containing p-cymene is subjected to vacuum fractionation to obtain 3-pairs of Alkenes by-products and p-cymene products.

[0073] The fractionation described in step (4) is vacuum fractionation, and concrete operation is as follows:

[0074] S1: First discharge the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com