Fabricated cement fiberboard composite wallboard, manufacturing process and outer wall

A cement fiberboard and composite wallboard technology, which is applied in the industrial field, can solve the problems that the quality of on-site welding and anticorrosion is difficult to guarantee, it is not suitable to use autoclaved aerated concrete panels, and there are many installation procedures for on-site composite walls, so that the installation quality is easy to control, Good waterproof effect, good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0032] As in Example 1: the components of the foam concrete are: 80 parts of rapid-hardening Portland cement, 4 parts of lime, 0.4 part of ceramsite, 3 parts of slurry stabilizer, 48 parts of water, and 0.1 part of foam; Example 2 : 90 parts of rapid-hardening portland cement, 5 parts of lime, 0.5 part of ceramsite, 7 parts of slurry stabilizer, 55 parts of water, and 0.5 part of foam; embodiment three: 80 parts of rapid-hardening portland cement, 5 parts of lime 0.4 parts of ceramsite, 3 parts of slurry stabilizer, 55 parts of water, and 0.4 parts of foam. Example 4: 85 parts of rapid-hardening Portland cement, 4.5 parts of lime, 0.45 parts of ceramsite, 5 parts of slurry stabilizer, 51 parts of water, and 0.3 part of foam.

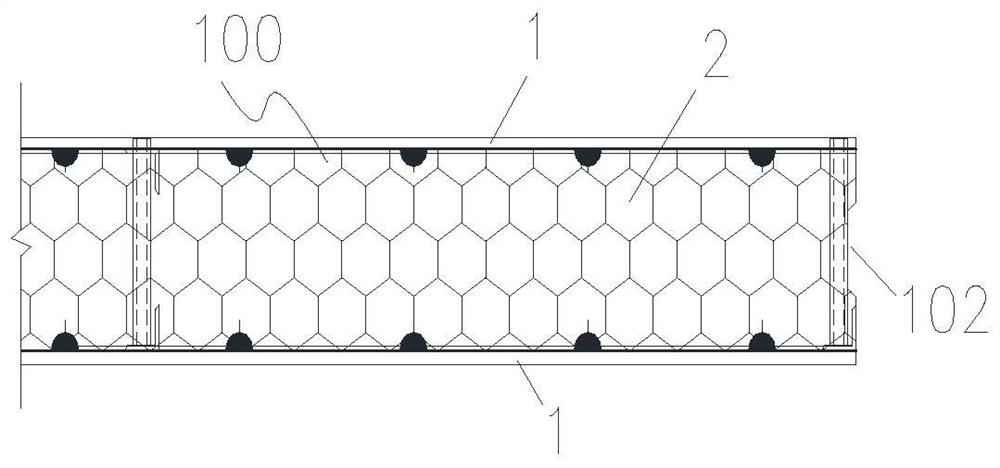

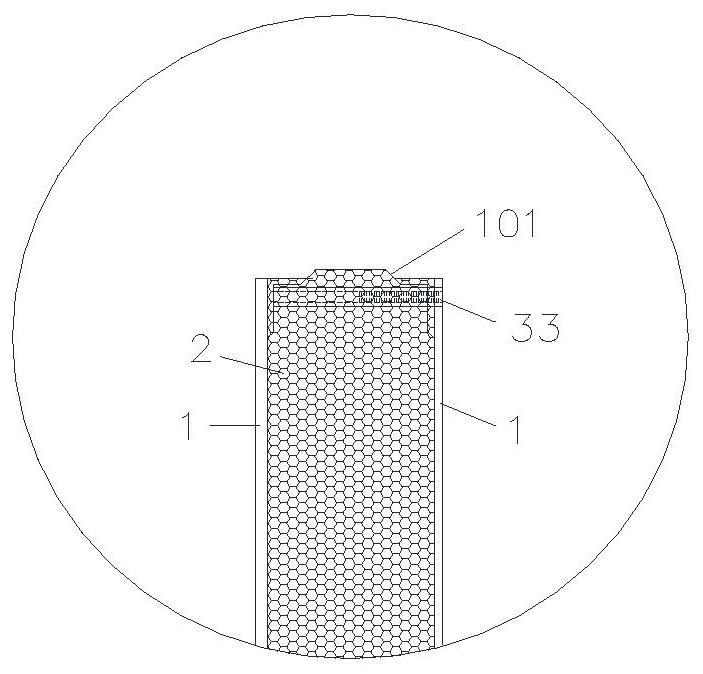

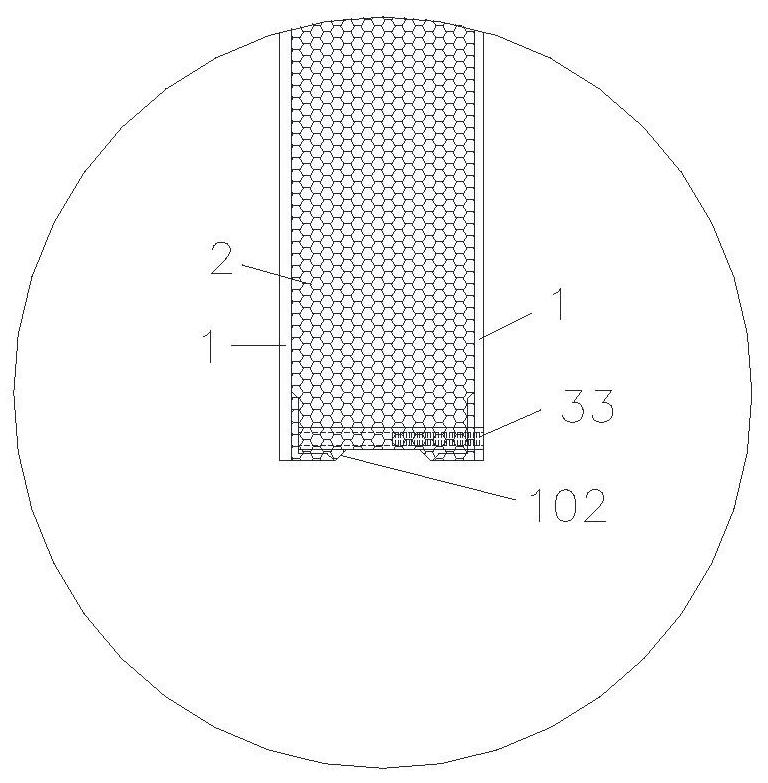

[0033] That is, the overall structure of the prefabricated cement fiberboard foamed concrete composite wallboard of the present invention: 9mm or 12mm thick cement fiberboard + 150mm foam concrete (light steel keel stress structure is added in the middle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com