Preparation method of spherical boron nitride

A boron nitride, spherical technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of low mechanical strength, easy breakage, large specific surface area, etc. The effect of hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

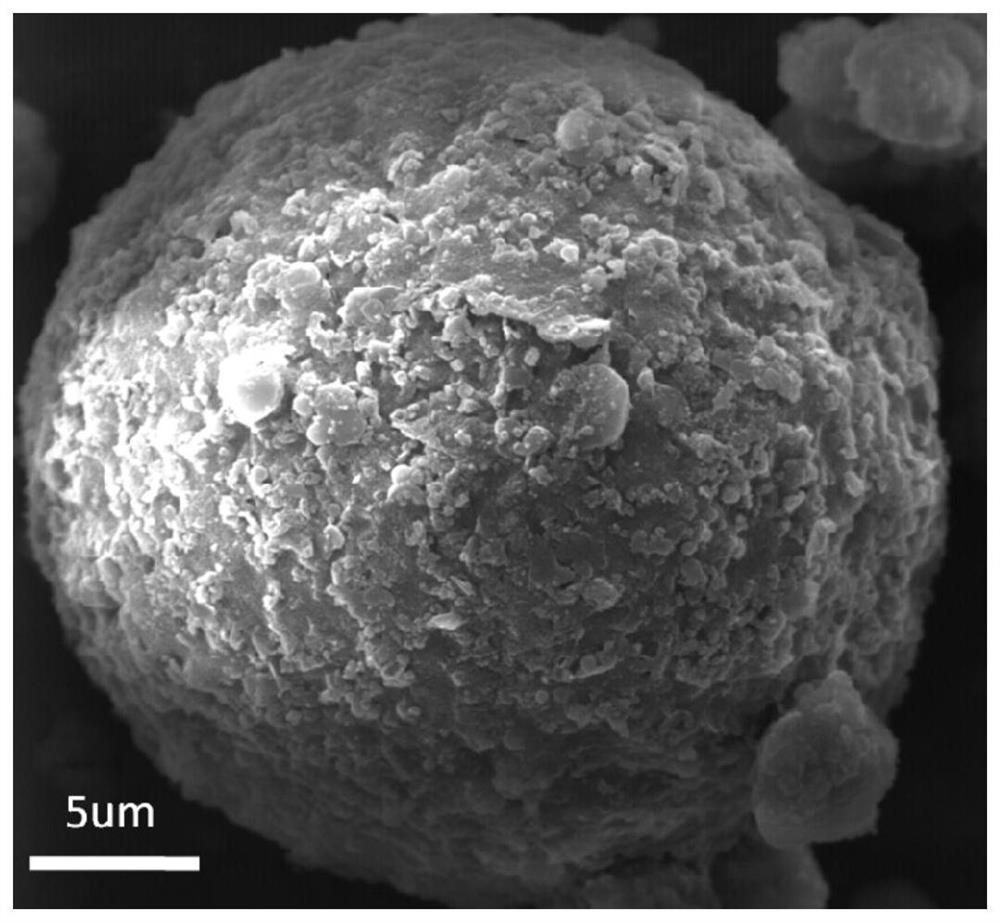

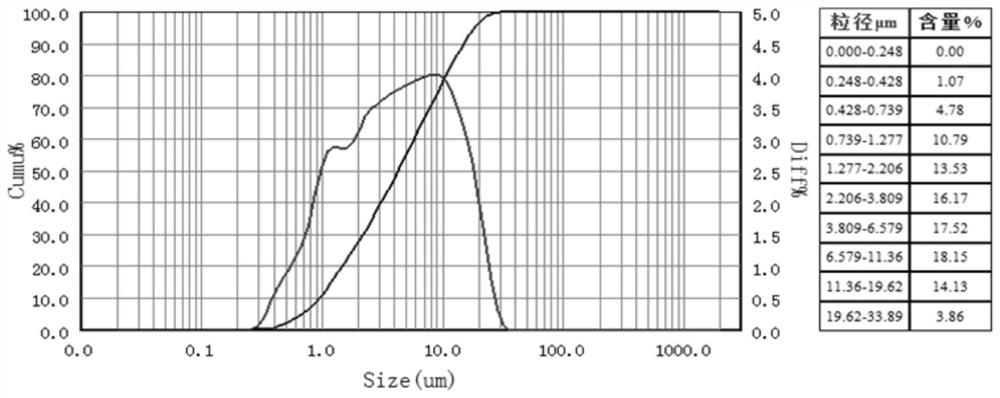

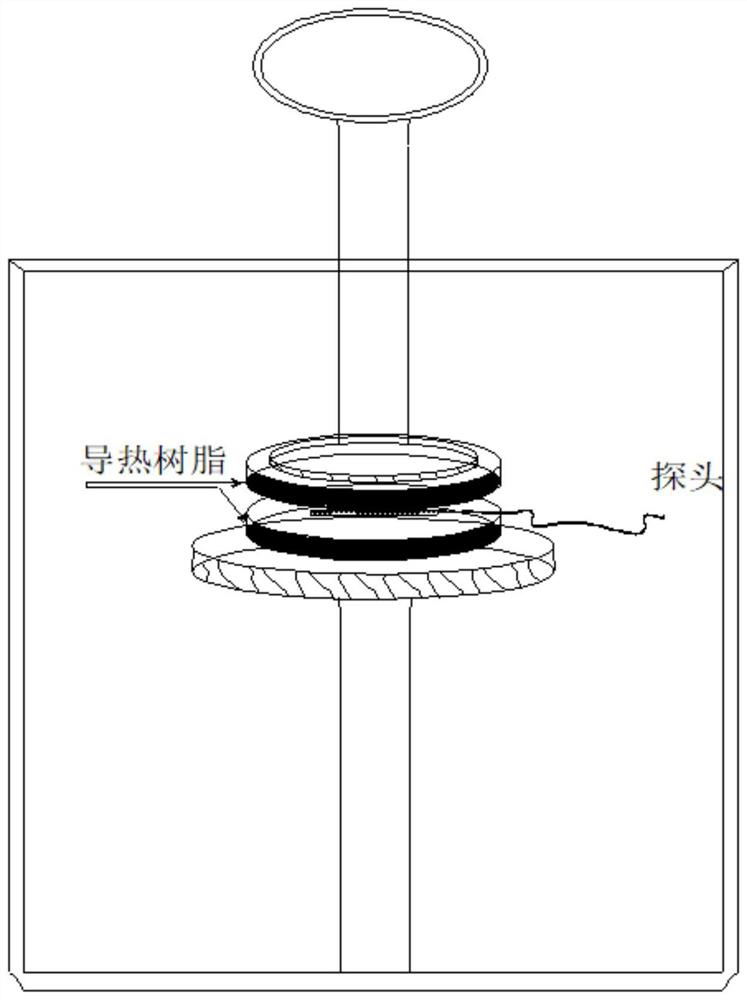

Embodiment 1

[0032] First, boron nitride powder with a particle size of 30um, fatty alcohol polyoxyethylene ether, glucose and water are mixed uniformly at a mass ratio of 10:0.5:2:87.5. Then transfer it to an isostatic pressure peeling machine, the pressure is 300MPa, after 10mins, it is sealed and heated to 80°C and kept for 6h. Then, centrifuge and filter to remove excess glucose, dry at 80°C to obtain boron nitride powder; disperse boron nitride powder and aluminum sol in water according to a certain proportion, boron nitride powder accounts for 30%, aluminum sol accounts for ratio of 7%, and then adjust the pH value to between 7 and 8 with ammonia water. Finally, pass it into the spray tower for spray drying, the feed rate is 5L / h, the centrifugal disc speed is 18000r / min, the air inlet temperature is 280°C, and the air outlet temperature is 120°C to obtain primary spherical boron nitride. Calcined at 800°C for 6h in an atmosphere, cooled, and sieved with 100 mesh to obtain spherical...

Embodiment 2

[0040] First, mix boron nitride powder with a particle size of 20um, fatty alcohol polyoxyethylene ether, glucose and water in a mass ratio of 10:0.5:2:87.5. Then transfer it to an isostatic pressure peeling machine, the pressure is 300MPa, after 10mins, it is sealed and heated to 80°C and kept for 6h. Then, centrifuge and filter to remove excess glucose, dry at 80°C to obtain boron nitride powder; disperse boron nitride powder and aluminum sol in water according to a certain proportion, boron nitride powder accounts for 30%, aluminum sol accounts for ratio of 7%, and then adjust the pH value to between 7 and 8 with ammonia water. Finally, pass it into the spray tower for spray drying, the feed rate is 5L / h, the centrifugal disc speed is 18000r / min, the air inlet temperature is 280°C, and the air outlet temperature is 120°C to obtain primary spherical boron nitride. Calcined at 800°C for 6 hours in an atmosphere, cooled, and sieved through a 100-mesh sieve to obtain spherical...

Embodiment 3

[0043] First, mix boron nitride powder with a particle size of 10um, fatty alcohol polyoxyethylene ether, glucose and water in a mass ratio of 10:0.5:2:87.5. Then transfer it to an isostatic pressure peeling machine, the pressure is 300MPa, after 10mins, it is sealed and heated to 80°C and kept for 6h. Then, centrifuge and filter to remove excess glucose, dry at 80°C to obtain boron nitride powder; disperse boron nitride powder and aluminum sol in water according to a certain proportion, boron nitride powder accounts for 30%, aluminum sol accounts for ratio of 7%, and then adjust the pH value to between 7 and 8 with ammonia water. Finally, pass it into the spray tower for spray drying, the feed rate is 5L / h, the centrifugal disc speed is 18000r / min, the air inlet temperature is 280°C, and the air outlet temperature is 120°C to obtain primary spherical boron nitride. Calcined at 800°C for 6 hours in an atmosphere, cooled, and sieved through a 100-mesh sieve to obtain spherical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com