Preparation method of boron carbide composite ceramic plate and bulletproof flashboard

A technology of composite ceramic plates and bulletproof inserts, applied in the structure of armor plates, protective equipment, offensive equipment, etc., can solve the problems of low fracture toughness, high price, high brittleness, etc., achieve uniform distribution, reduce consumption, and improve fracture The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

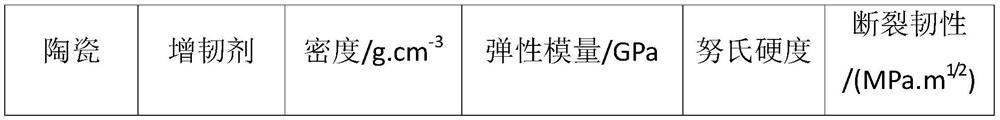

Examples

Embodiment 1

[0034] The present embodiment relates to a method for preparing a boron carbide composite ceramic plate, which includes the following steps:

[0035] S1: Material selection: use boron carbide powder with D50<3um as raw material, and graphene material as sintering aid;

[0036] S2: Prepare a graphene suspension: Dissolve the dispersing aid in water or alcohol to make a solution, then add graphene to the solution, and disperse it by a high-pressure homogenization process for 1-24 hours to obtain graphene with uniform dispersion of graphene suspension; wherein, the mass ratio of graphene in the dispersion is between 1% and 10%, the graphene sheet diameter D90 in the prepared graphene suspension is less than 1 μm, and the number of layers is less than 10 layers;

[0037] S3: the boron carbide powder obtained in step S1 and the graphene suspension obtained in step S2 are added in a three-roll mill and mixed, wherein the rollers of the slow roller, the medium speed roller and the fa...

Embodiment 2

[0043] This embodiment relates to a bulletproof insert, which sequentially includes a waterproof layer, a crack arresting layer, a bulletproof layer, a transition layer, a titanium alloy bulletproof layer and a buffer layer along the direction of the bullet. A multi-curved plate made of the boron carbide composite ceramic plate described in Example 1. Wherein, the waterproof layer adopts 0.5mm thick polyurea nanocoating or Oxford waterproof cloth.

[0044] As a further improvement of this embodiment, the crack arresting layer adopts aramid woven fabric.

[0045] As a further improvement scheme of this embodiment, the transition layer adopts aramid woven fabric.

[0046] As a further improvement solution of this embodiment, the buffer layer adopts a PE board.

[0047] As a further improvement scheme of this embodiment, the material of the bulletproof layer of the titanium alloy plate is Ti5322 or TC4 alloy.

[0048] As a further improvement of this embodiment, the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com