Organic mixed waste gas rare earth-based catalytic combustion catalyst and preparation method and application thereof

A catalytic combustion and catalyst technology, applied in the direction of combustion methods, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effects of reducing carbon deposition, improving processing capacity, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

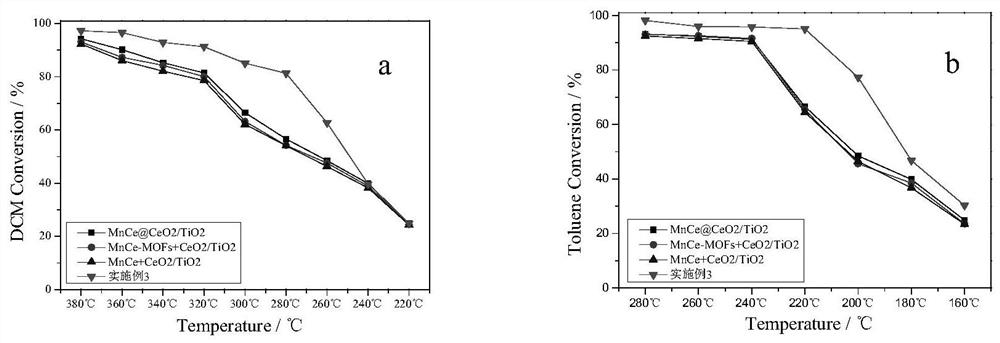

Examples

Embodiment 1

[0031]A rare earth-based catalytic combustion catalyst for organic mixed waste gas, composed of the following raw materials: tetrahydrate and manganese chloride, cobalt nitrate hexahydrate, cerium nitrate hexahydrate, 2,5-dihydroxyterephthalic acid, N,N-dimethyl Methyl formamide, anhydrous ethanol and anhydrous methanol, (1) 0.16g of manganese chloride tetrahydrate and 0.43g of cerium nitrate hexahydrate are dissolved in 0.13g of 2,5-dihydroxyterephthalic acid (DHTP) and 53mL of N,N-dimethylformamide (DMF) in 10mL of anhydrous ethanol aqueous solution (alcohol: water = 1:1); (2) Put the mixed solution obtained in the previous step into a polytetrafluoroethylene lined React in a stainless steel autoclave at 135°C for 24 hours, cool to room temperature after the reaction, filter, wash and soak the reactants in methanol; (3) Use 99.7% methanol solvent to replace once every 12 hours for the next 96 hours, and then replace the above The prepared CeMn-MOFs product was placed in a vacuum o...

Embodiment 2

[0034]A rare earth-based catalytic combustion catalyst for organic mixed waste gas, composed of the following raw materials: tetrahydrate and manganese chloride, cobalt nitrate hexahydrate, cerium nitrate hexahydrate, 2,5-dihydroxyterephthalic acid, N,N-dimethyl Methyl formamide, anhydrous ethanol and anhydrous methanol, (1) 0.8g of manganese chloride tetrahydrate and 4.3g of cerium nitrate hexahydrate were dissolved in 0.13g of 2,5-dihydroxyterephthalic acid (DHTP) and 53mL of N,N-dimethylformamide (DMF) in 10mL of anhydrous ethanol aqueous solution (alcohol: water = 1:1); (2) Put the mixed solution obtained in the previous step into a polytetrafluoroethylene lined React in a stainless steel autoclave at 135°C for 24 hours, cool to room temperature after the reaction, filter, wash and soak the reactants in methanol; (3) Use 99.7% methanol solvent to replace once every 12 hours for the next 84 hours, and then replace the above The prepared CeMn-MOFs product was placed in a vacuum ov...

Embodiment 3

[0037]A rare earth-based catalytic combustion catalyst for organic mixed waste gas, composed of the following raw materials: tetrahydrate and manganese chloride, cobalt nitrate hexahydrate, cerium nitrate hexahydrate, 2,5-dihydroxyterephthalic acid, N,N-dimethyl (1) 1.6g of manganese chloride tetrahydrate and 4.3g of cerium nitrate hexahydrate are dissolved in 0.13g of 2,5-dihydroxyterephthalic acid (DHTP) and 53mL of N,N-dimethylformamide (DMF) in 10mL of anhydrous ethanol aqueous solution (alcohol: water = 1:1); (2) Put the mixed solution obtained in the previous step into a polytetrafluoroethylene lined React in a stainless steel autoclave at 150°C for 24 hours. After the reaction, cool to room temperature, filter, wash and soak the reactants in methanol; (3) Use 99.7% methanol solvent to replace once every 12 hours for the next 84 hours, and then replace the above The prepared CeMn-MOFs product was placed in a vacuum oven at 60°C for drying overnight, and finally stored in a des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com