High-dielectric low-loss resin-based nanocomposites for x-band and methods thereof

A nano-composite material, high dielectric technology, applied in the field of composite materials, can solve the problems of high dielectric loss, inability to meet the requirements of the dielectric properties of materials, limited improvement of the dielectric properties of composite materials, etc., to improve the dielectric constant. , reduce defect density and enhance the effect of interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

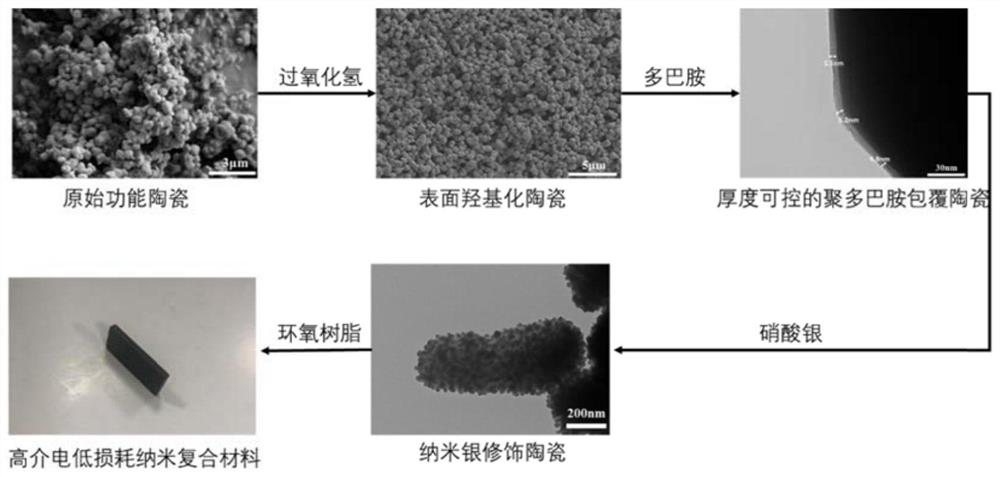

[0035] Such as figure 1 As shown, in this example, a high-dielectric and low-loss resin-based nanocomposite material for the X-band is prepared, and the preparation method is as follows:

[0036] 1) Select barium titanate ceramic particles with an average particle size of 500nm (that is, dielectric ceramics, denoted as BT), and dry them in an oven at 60°C for later use. The thermosetting resin is selected from bisphenol A epoxy resin, wherein the mass ratio of epoxy resin to curing agent is 10:3, and the thermosetting resin is placed in a dry box for use.

[0037] 2) Weigh 30 g of barium titanate ceramic particles and disperse them in 160 ml of 30% H 2 o 2In the aqueous solution, the mixed system was ultrasonically dispersed for 10 min using an ultrasonic cell pulverizer to form a uniform and stable suspension. Then, it was placed in a three-necked flask at 105° C. for 4 hours of magnetic stirring reaction, so that the surface of the barium titanate ceramic particles was hy...

Embodiment 2

[0045] In this example, a high-dielectric and low-loss resin-based nanocomposite material for the X-band is prepared. The preparation method is the same as in Example 1, except that BT, BT-OH, BT-PDA and BT are weighed in step 5). -PDA-Ag 2.695g is used as the added phase, thereby making the barium titanate ceramic particles / resin-based nanocomposite material (BT / EP-10) and the hydroxylated barium titanate particles / resin-based nanocomposite material with an added phase content of 10vol% respectively. Composite material (BT-OH / EP-10), polydopamine-coated barium titanate particles / resin-based nanocomposite (BT-PDA / EP-10), nano-silver particles modified core-shell-satellite hierarchical structure Barium titanate particles / resin matrix nanocomposite (BT-PDA-Ag / EP-10).

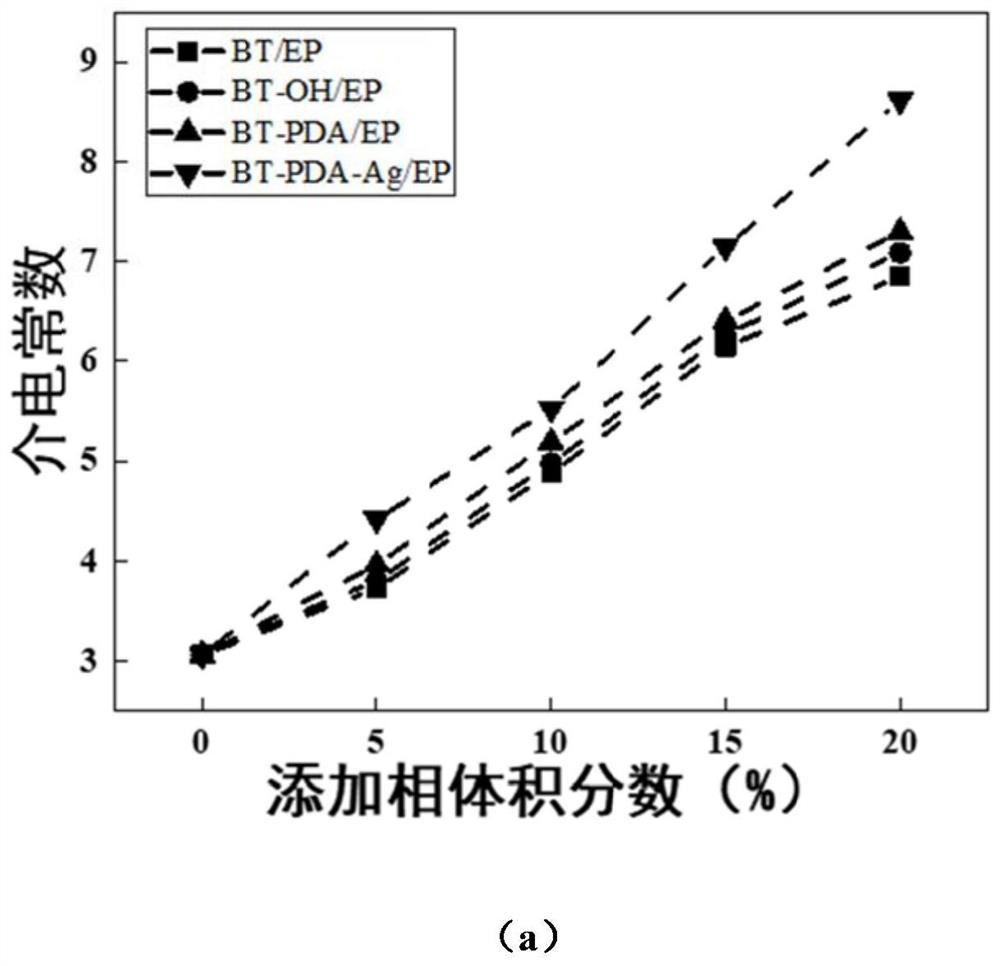

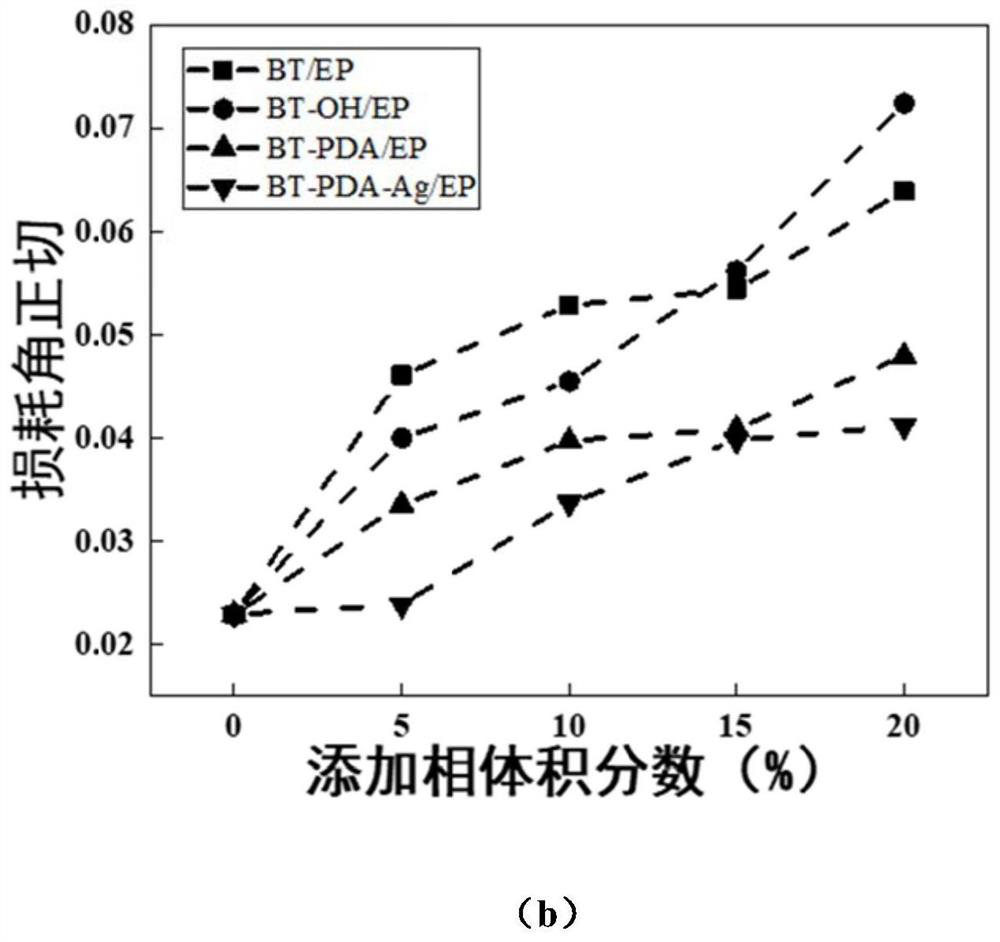

[0046] Such as figure 2 As shown, in this embodiment, the additive phase content in the resin-based nanocomposite is 10vol%, and the dielectric constants in the X-band range from low to high are BT / EP-10, BT-OH / ...

Embodiment 3

[0048] In this example, a high-dielectric and low-loss resin-based nanocomposite material for the X-band is prepared. The preparation method is the same as in Example 1, except that BT, BT-OH, BT-PDA and BT are weighed in step 5). -PDA-Ag 4.279g is used as the added phase, thereby making the barium titanate ceramic particle / resin-based nanocomposite material (BT / EP-15) and the hydroxylated barium titanate particle / resin-based nanocomposite material with an added phase content of 15vol% respectively. Composite material (BT-OH / EP-15), polydopamine-coated barium titanate particles / resin-based nanocomposite material (BT-PDA / EP-15), nano-silver particles modified core-shell-satellite hierarchical structure Barium titanate particles / resin matrix nanocomposite (BT-PDA-Ag / EP-15).

[0049] Such as figure 2 As shown, in this embodiment, the additive phase content in the resin-based nanocomposite is 15vol%, and the dielectric constants in the X-band range from low to high are BT / EP-15,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com