Red perovskite light emitting diode based on mixed halogen and preparation method thereof

A technology of light-emitting diodes and perovskites, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor spectral stability and low efficiency of red light devices, so as to reduce movement, improve charge transport performance, and improve Effects of Brightness and Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

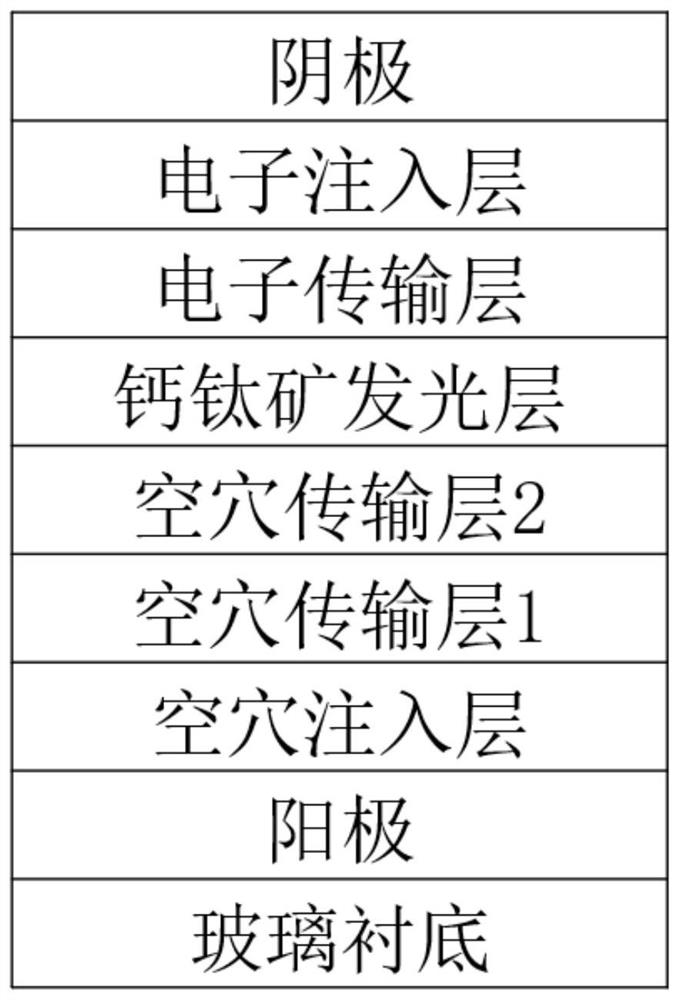

[0056] This embodiment provides a red-light perovskite light-emitting diode mixed with halogen. The formation of the perovskite layer uses ethyl acetate as an anti-solvent to accelerate the crystallization of the perovskite. It sequentially includes a glass substrate, an anode, a hole injection layer, a hole transport layer 1, a hole transport layer 2, a red perovskite light-emitting layer, an electron transport layer, an electron injection layer and a cathode. The preparation method is as follows:

[0057] (1) According to CsI is 0.3mol / L, PbI 2 The perovskite precursor solution was prepared at a concentration of 0.3mol / L and PEABr of 0.18mol / L, and the solvent used was DMSO.

[0058] (2) After the cleaned ITO glass was placed in a UV ozone cleaning machine for 15 minutes, the commercial PEDOT:PSS aqueous solution was directly spin-coated on the treated ITO glass at a speed of 4000rpm. The spin-coating time was 30 seconds, and Annealed at 150°C for 30 minutes to obtain a PED...

Embodiment 2

[0071] The device structure and preparation method of the perovskite light-emitting diode in this embodiment are basically the same as in Example 1, and ethyl acetate is used as the anti-solvent. The difference is that the ratio CsI of the perovskite precursor solution in this embodiment is 0.3mol / L, PbI 2 The concentration is 0.36mol / L and PEABr is 0.18mol / L. That is, compared to Pb / Cs=1 in Example 1, Pb / Cs=1.2 in this example.

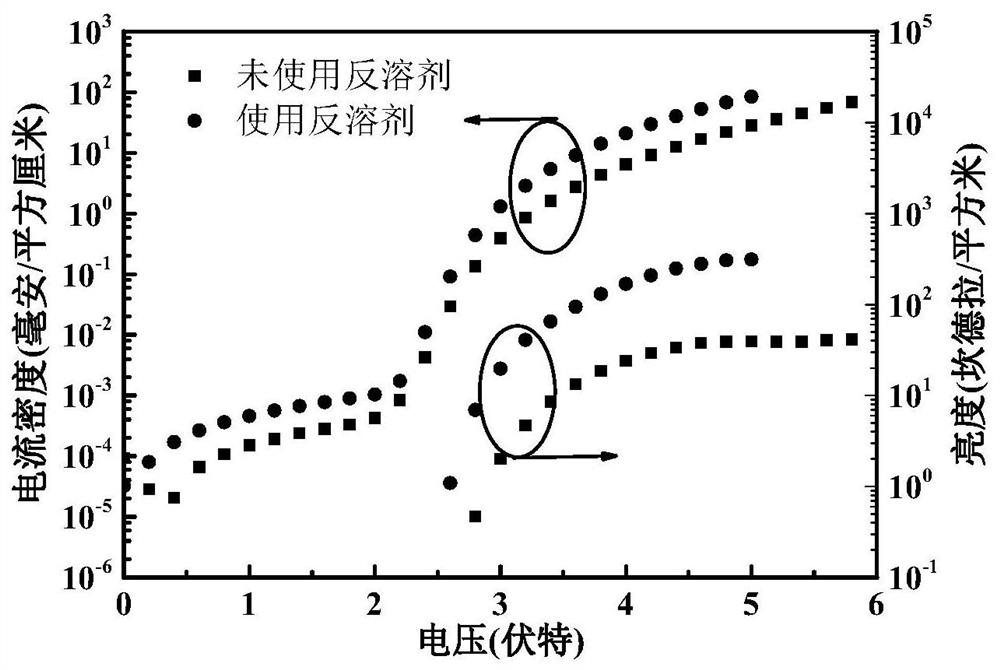

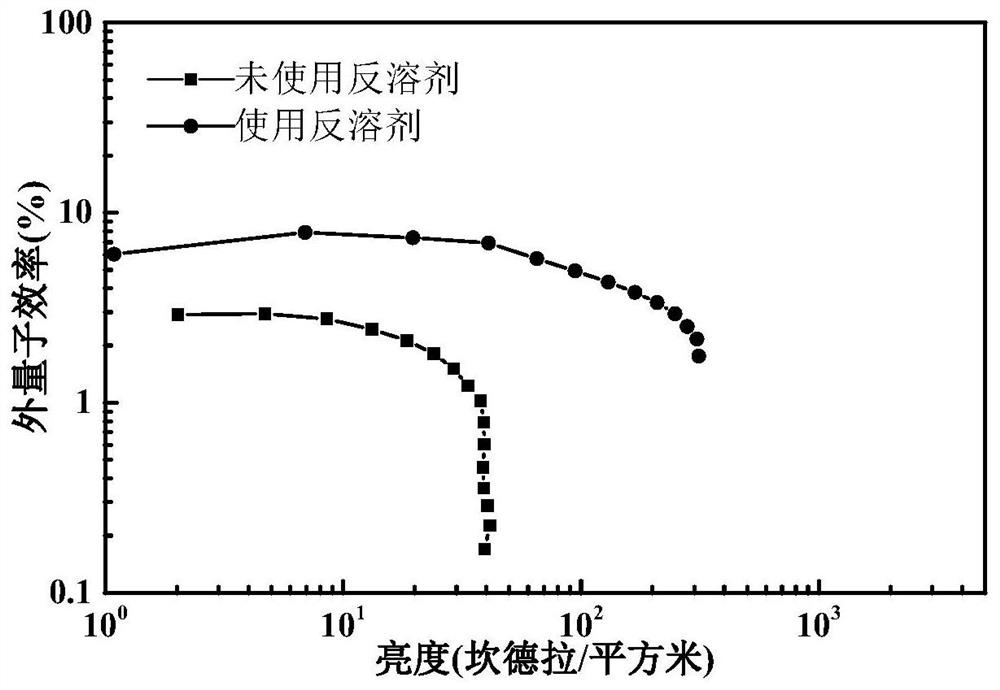

[0072] according to Figure 10 In (b) and (c), it can be seen that in the formation process of red light perovskite, a slight excess of Pb over Cs is more conducive to the crystallization of the perovskite film, and the perovskite film with Pb / Cs=1.2 is more favorable than Pb / The perovskite film with Cs=1 can form more columnar crystal structures, and the performance comparison in Table 2 and Figure 5 and Figure 6 It can be seen that this columnar crystal has a great impact on the performance of the device. After a slight excess of Pb over Cs,...

Embodiment 3

[0076] The device structure and preparation method of the perovskite light-emitting diode in this embodiment are basically the same as in Example 1, and the concentration of each anion and cation in the perovskite precursor solution is also the same, the difference is that in the precursor solution of this embodiment Br - From lead bromide (PbBr 2 ). The ratio of each component is shown in Table 3

[0077] Table 3. Comparison of the distribution ratio of each component of the red light perovskite precursor solution (unit: mol / L)

[0078]

[0079] According to Table 4 and Figure 7 as well as Figure 8 The results in show that under the same ionic composition of the red light perovskite, the Br - From PbBr 2 The performance of the device is better, the maximum external quantum efficiency can reach 16%, and the maximum brightness can reach 3631 candela / square meter.

[0080] Table 4. Comparison of device performance parameters of red perovskite light-emitting diodes

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com