High-barrier environment-friendly degradable coffee capsule cover film and preparation method thereof

A coffee capsule, high barrier technology, applied in the direction of chemical instruments and methods, sustainable manufacturing/processing, adhesives, etc., can solve the problems of non-degradable, environmental pollution, coffee capsule waste plastics, etc., achieve good water and oxygen barrier performance, alleviate Pollution, the effect of mitigating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

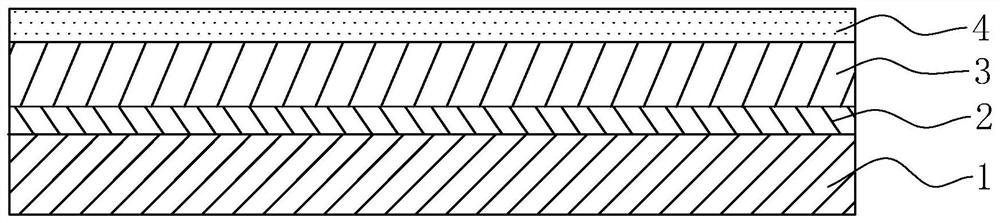

Image

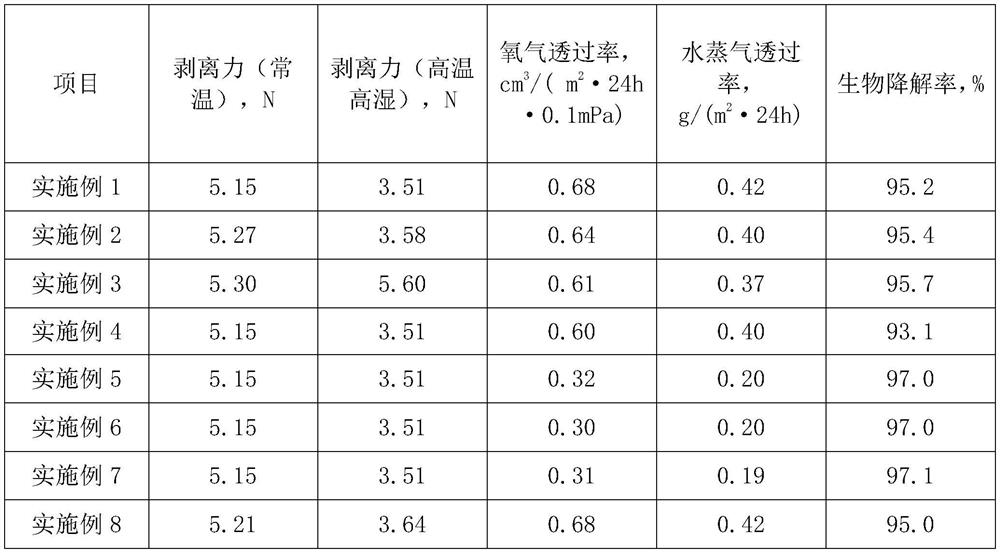

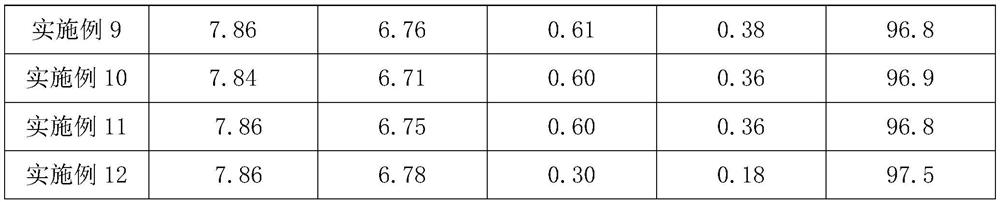

Examples

preparation example 1

[0041] Preparation example 1 of water-based adhesive: take 20kg of water, heat it to 95°C, add 10kg of absolute ethanol, 40kg of ethylene-vinyl acetate copolymer emulsion, 5kg of polyvinyl alcohol, and 2kg of polyvinyl butyral while stirring , 2kg of polyvinylpyrrolidone and 0.3kg of phenyl-o-hydroxybenzoate were stirred for 20min at a speed of 200r / min, then 0.06kg of bactericide and 0.2kg of defoamer were added, and stirring was continued for 5min. After cooling, a water-based adhesive was obtained.

preparation example 2

[0042] Preparation example 2 of water-based adhesive: Take 22.5kg of water, heat it to 97°C, add 11kg of absolute ethanol, 42.5kg of ethylene-vinyl acetate copolymer emulsion, 7.5kg of polyvinyl alcohol, 2.5kg of polyethylene while stirring Alcohol butyral, 2.5kg polyvinylpyrrolidone and 0.4kg phenyl o-hydroxybenzoate were stirred for 25min at a speed of 250r / min, then added 0.08kg bactericide and 0.3kg defoamer, continued to stir for 8min, and after cooling, obtained Water-based adhesive.

preparation example 3

[0043] Preparation example 3 of water-based adhesive: take 25kg of water, heat it to 98°C, add 12kg of absolute ethanol, 45kg of ethylene-vinyl acetate copolymer emulsion, 10kg of polyvinyl alcohol, and 3kg of polyvinyl butyral while stirring , 3kg of polyvinylpyrrolidone and 0.5kg of phenyl o-hydroxybenzoate were stirred for 30min at a speed of 300r / min, then 0.1kg of bactericide and 0.4kg of defoamer were added, and stirring was continued for 10min. After cooling, a water-based adhesive was obtained.

[0044] Preparation example of water-based barrier coating

[0045] The polyvinyl alcohol in the following preparation examples is selected from the PVA100-27 of 1799 provided by Sinopec; the nano-montmorillonite is provided by Shandong Sishui Shengfeng Bentonite Co., Ltd.; the nano-titanium dioxide is provided by Jinan Baolijin Chemical Co., Ltd.; The content of sodium metaphosphate provided by Shandong Zhenhua Industrial Co., Ltd. is 68%; the polyvinyl butyral is selected fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com