Process method and device for high-performance wire rod production

A production process, high-performance technology, applied in the direction of manufacturing tools, metal processing equipment, workpiece surface treatment equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The T2 strip with a thickness of 100μm and a width of 5mm is subjected to a single pass of liquid-cooled temperature controlled ultrasonic rolling continuous impact thinning treatment. The chemical composition of the T2 rolled pure copper foil is shown in Table 1:

[0059] Table 1 Chemical composition of T2 rolled pure copper foil (%)

[0060]

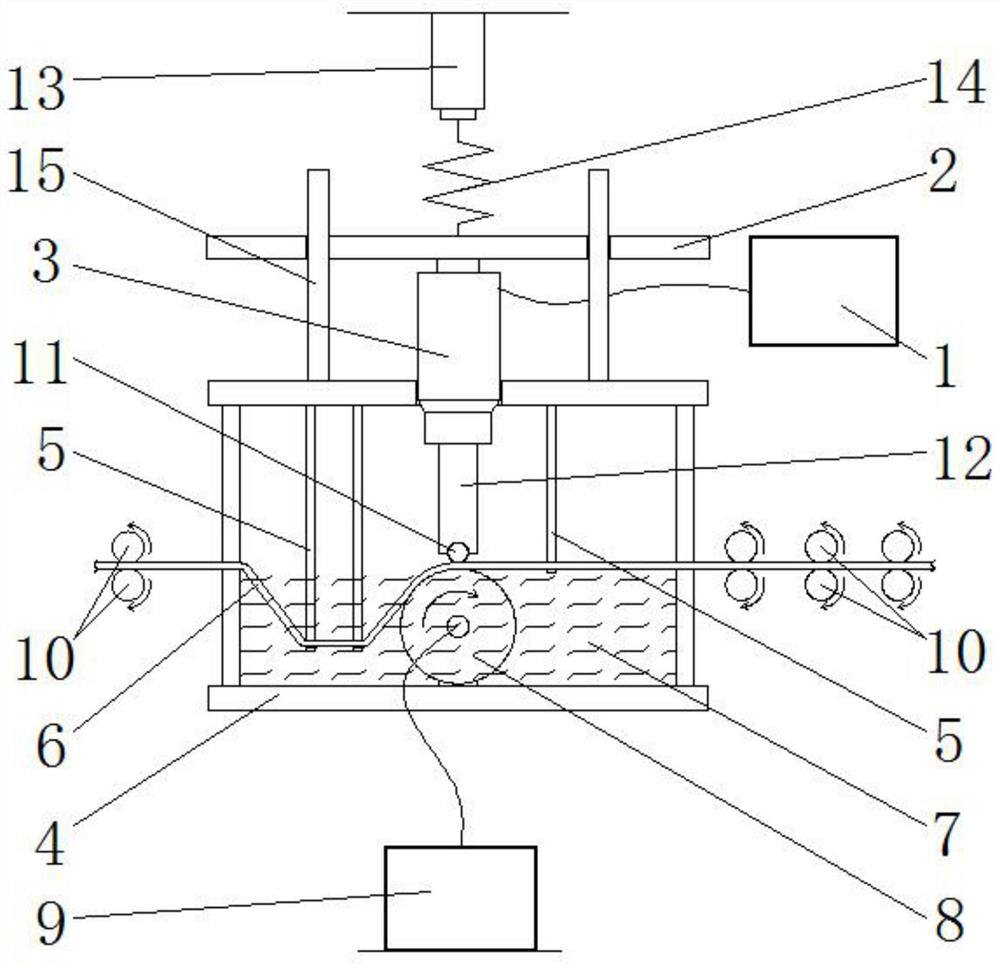

[0061] The low-temperature ultrasonic rolling impact device used is such as figure 1 , figure 2 , image 3 and Figure 4 As shown,

[0062] The device includes a closed liquid cooling temperature control mechanism, a traction transmission mechanism and an ultrasonic rolling impact mechanism;

[0063] The airtight liquid cooling temperature control mechanism includes an airtight container 4 containing a cooling liquid 7 inside. The outer shell of the airtight container 4 has a double-layer structure, and the inner layer is an insulating layer made of an insulating material; the airtight container 4 The two opposite sides in the length d...

Embodiment 2

[0080] The 304 austenitic stainless steel wire rod with a width and thickness of 300 μm was subjected to a multi-pass liquid-cooled temperature-controlled ultrasonic rolling continuous impact treatment, and the low-temperature ultrasonic rolling impact device was the same as that in Example 1.

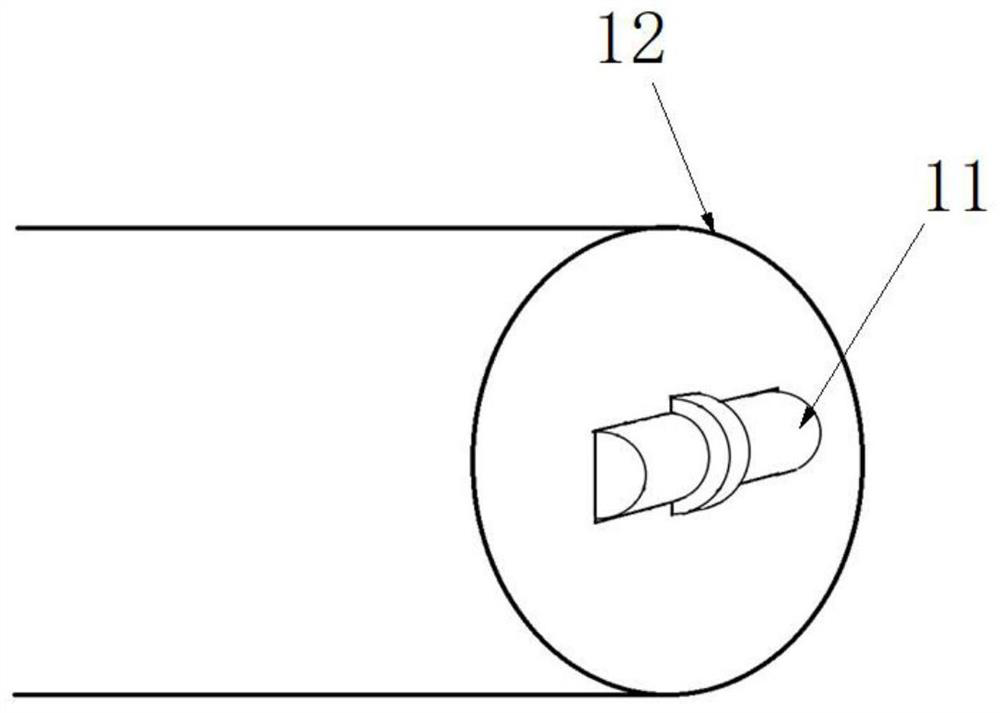

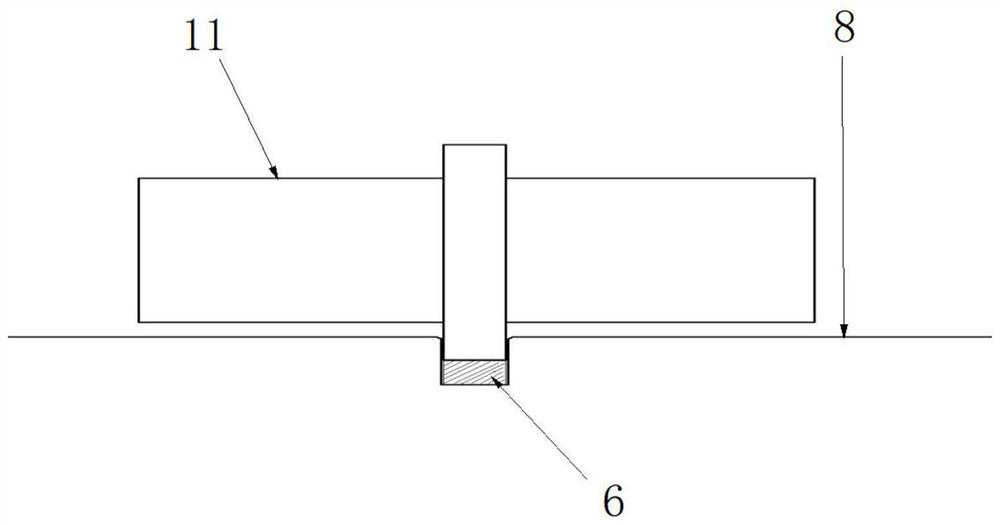

[0081] The above-mentioned ultrasonic transducer 3 converts the electric oscillation into 20kHz ultrasonic, the ultrasonic horn further amplifies the amplitude, and drives the GCr15 bearing steel rigid impact roller 11 on the top of the ultrasonic tool head 12 (diameter 6mm, width 10mm; surface groove width 300μm, Depth 1mm; surface roughness (Ra): 0.1μm, hardness: 64HRC) produce longitudinal high frequency vibration; use laser displacement sensor to measure the vibration amplitude, the end amplitude is 30μm; the ultrasonic horn is fixed to impact the rigid roller The distance between 11 and the rigid roller 8 is the sum of the ultrasonic amplitude and half the thickness of the wire, that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com