Method for preparing zinc-tantalum alloy by solvating ionic liquid

An ionic liquid and solvation technology, applied in the field of metallurgy, can solve problems such as complex operation, difficulty in zinc-tantalum alloy, and narrow electrochemical window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A 1,3-dimethyl-2-imidazolinone-ZnCl 2 -TaCl 5 A preparation method for preparing a zinc-tantalum alloy by solvating an ionic liquid, the specific operation comprising the following steps:

[0026] Step 1, at room temperature, under the atmospheric atmosphere, 2.933g of ZnCl 2 Slowly add to 10ml 1,3-dimethyl-2-imidazolidinone to dissolve, then slowly add 0.175g of TaCl 5 , forming 1,3-dimethyl-2-imidazolinone-ZnCl 2 -TaCl 5 Solvated ionic liquids;

[0027] Step 2. Stir and heat the intelligent digital display magnetic heating plate, control the temperature of the electrolytic cell to 40°C, and use the three-electrode system to conduct electrodeposition for 0.3h under the conditions of a constant potential of -0.4V (vs. Ag); the working electrode is the cathode Tungsten sheet (99.99%, area 1cm 2 ), the counter electrode is a platinum sheet (99.99%, with an area of 1cm 2 ), the reference electrode is a silver wire (99.99%, radius=1mm); before electrodeposition, th...

Embodiment 2

[0030] The operation steps of this example are the same as those of Example 1, except that in this example, the electrodeposition temperature is 60°C, the working electrode potential is -0.6V, and the reaction is carried out for 1 hour; a dense and uniform micro-nano zinc-tantalum alloy is obtained coating. It is detected by EDS, and it can be known that the weight percentages of zinc and tantalum are 59.12% and 3.09% respectively.

Embodiment 3

[0032]The operation steps of this example are the same as those of Example 1, the difference is that in this example, the electrodeposition temperature is 80°C, the working electrode potential is -1.2V, and the reaction is carried out for 2 hours; a dense and uniform micro-nano zinc-tantalum alloy is obtained coating. It is detected by EDS, and it can be seen that the weight percentages of zinc and tantalum are 31.66% and 31.37% respectively.

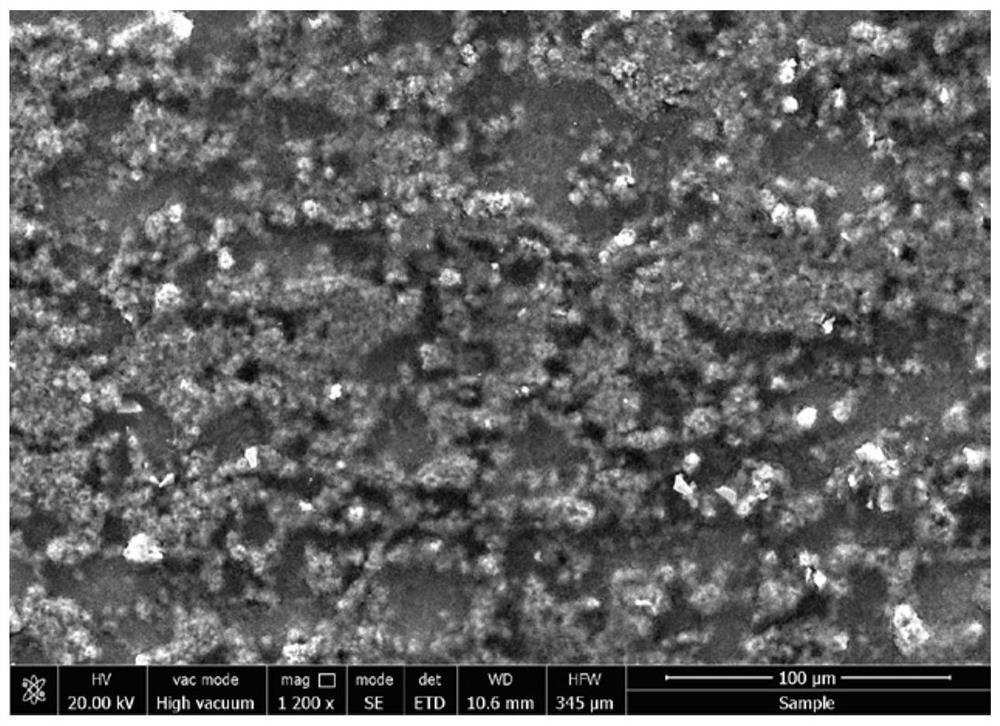

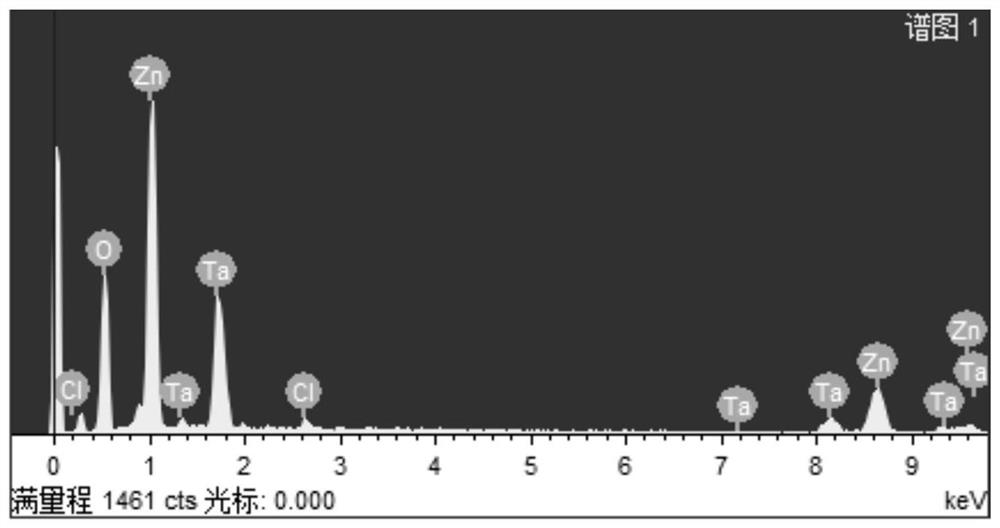

[0033] The scanning electron microscope picture of the zinc-tantalum alloy obtained in the present embodiment is as follows figure 1 As shown, the X-ray energy spectrum is shown as figure 2 shown. From figure 1 It can be seen that the obtained zinc-tantalum alloy has a dense and uniform microstructure, from figure 2 It can be seen that the obtained zinc-tantalum alloy has high content of zinc and tantalum, and only a small amount of other impurities.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com