Preparation method of chemical slurry plunger pump with composite coating and product thereof

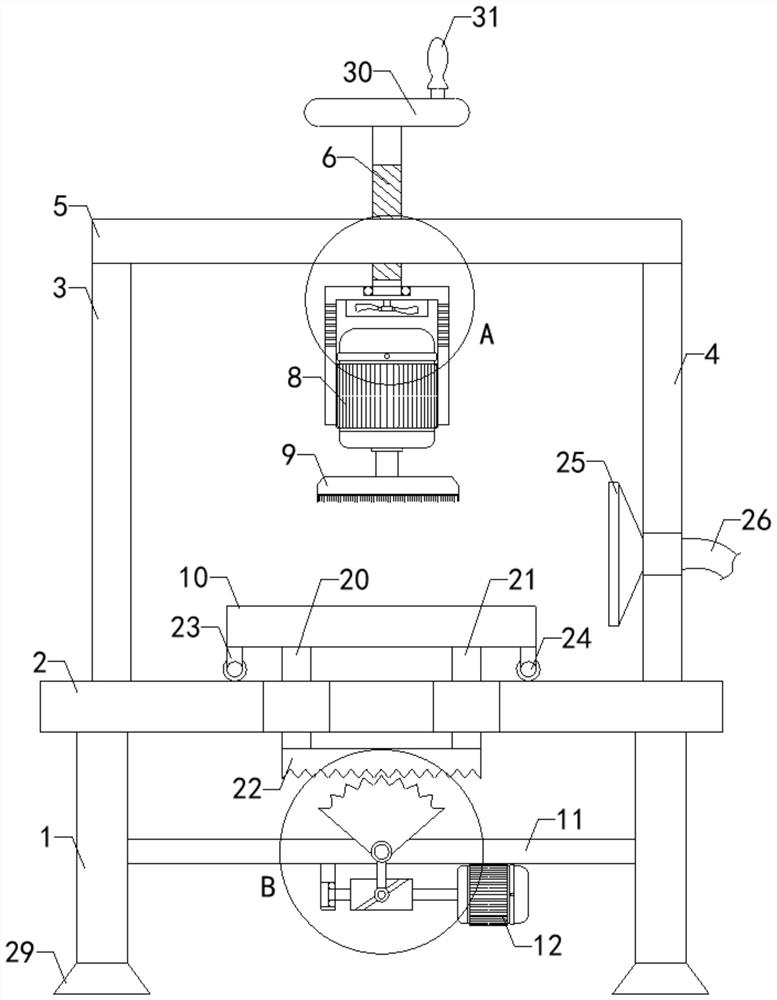

A composite coating and plunger pump technology, which is applied in the field of plunger pumps, can solve the problems of enhanced corrosion strength and lack of corrosion and wear resistance, and achieve good high temperature stability, reduce polishing time, and improve polishing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

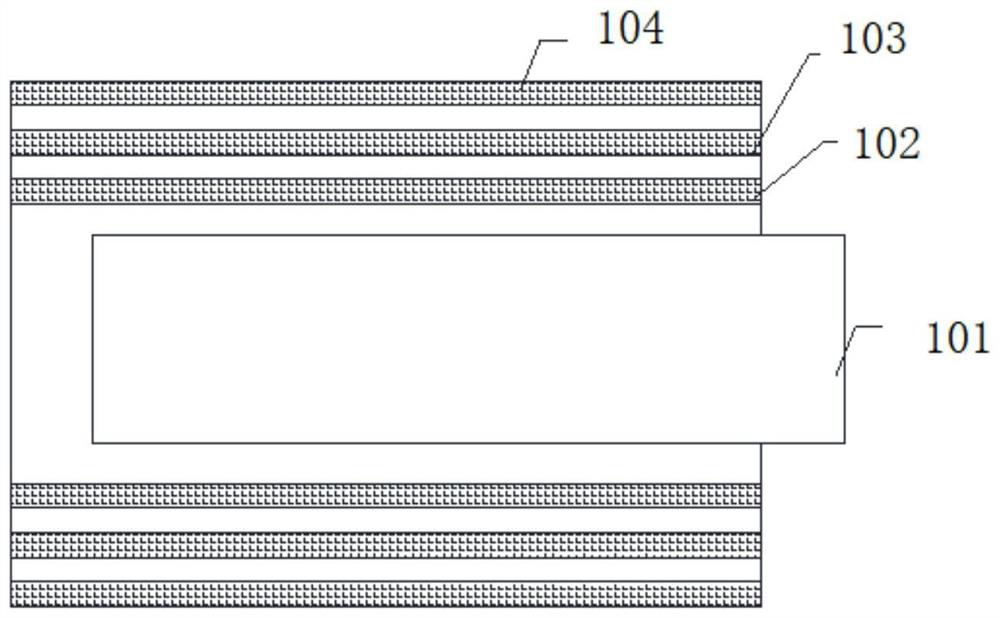

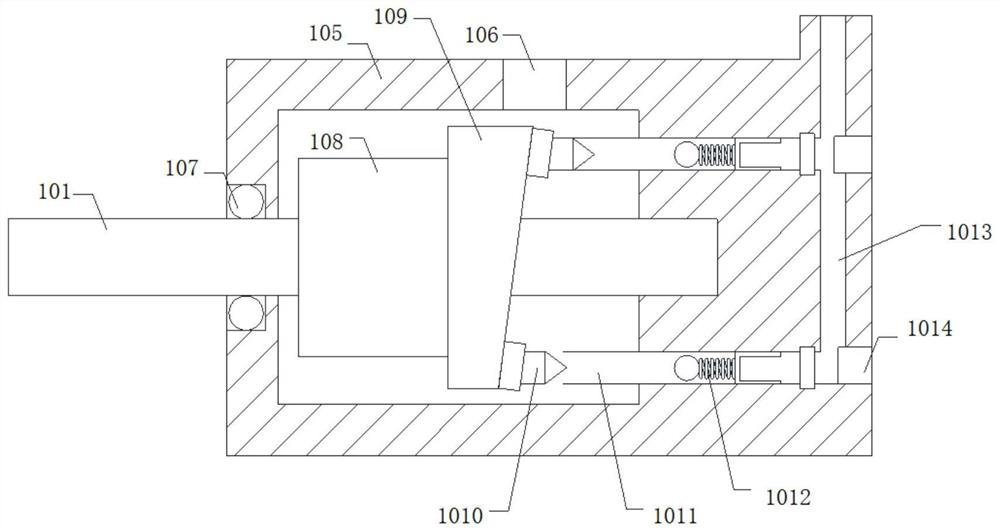

[0064] A chemical slurry plunger pump with a ceramic coating plunger, the technological process of which is:

[0065] 1. The part of the plunger base coating is cut down to reserve a coating thickness of 0.3mm, and the connection between the edge of the coating and the base should be chamfered at 45 degrees.

[0066] 2. The substrate is degreasing and baking treatment by organic solvent. Sandblasted with 24-grit brown corundum grit, and protected the non-coated area with a jig. Sandblasting compressed air pressure 5kg, distance 15cm, sandblasting angle 80°. After sandblasting, the surface of the substrate is evenly roughened and reaches Sa3 level.

[0067] 3. The substrate is preheated to 100°C, and the nickel-chromium primer coating is sprayed with the SG100 spray gun 730 nozzle of the plasma equipment of Thermach Company in the United States, the spraying current is 400A, the voltage is 38V, and the coating thickness is 0.1mm.

[0068] 4. Use the plasma equipment SG100 sp...

Embodiment 2

[0073] A preparation method of a chemical slurry plunger pump with a ceramic coating plunger, comprising the following preparation steps:

[0074] (1) Cut the part where the plunger base coating is located to reserve a coating thickness of 0.25mm, and the connection part between the coating edge and the base body is chamfered at 40 degrees;

[0075] (2) The substrate is degreased and baked by organic solvent; then sandblasted, the sandblasting compressed air pressure is 6kg, the sandblasting distance is 12cm, and the sandblasting angle is 85°; the non-coating area is protected by a fixture; thus the roughness can be increased ;

[0076] (3) The substrate is preheated to 90°C, and the nickel-chromium bottom coating is sprayed with a spray current of 350-450A, a voltage of 35V, and a coating thickness of 0.08mm;

[0077] (4) Spray chromium oxide coating, spray current 500A, voltage 40V, coating thickness 0.2mm;

[0078] (5) vacuum dipping and sealing is performed on the coatin...

Embodiment 3

[0082] A preparation method of a chemical slurry plunger pump with a ceramic coating plunger, comprising the following preparation steps:

[0083] (1) Cut down the part where the plunger base coating is located, and reserve a coating thickness of 0.25-0.35 mm, and the connection part between the coating edge and the base is chamfered at 40-50 degrees;

[0084] (2) The substrate is degreased and baked with organic solvent; then sandblasted, the sandblasting compressed air pressure is 4kg, the sandblasting distance is 8cm, and the sandblasting angle is 75°; the non-coating area is protected by a fixture;

[0085] (3) The substrate is preheated to 110°C, and the nickel-chromium bottom coating is sprayed with a spray current of 450A, a voltage of 40V, and a coating thickness of 0.12mm;

[0086] (4) Spray chromium oxide coating, spray current 600A, voltage 50V, coating thickness 0.4mm;

[0087] (5) vacuum dipping and sealing is carried out on the coating, the dipping time is 20 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com