Tibial prosthesis as well as preparation method and application thereof

A prosthesis, tibia technology, applied in the field of medical orthopedic bionic materials, can solve the problems of loosening, dislocation, poor fixation effect, etc., and achieve the effect of reducing stress shielding, low difficulty, and beneficial to initial stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a kind of preparation method of tantalum pentachloride gas: specifically comprise the following steps:

[0035] (1) Put medical pure tantalum in the reaction chamber (the reaction chamber is a quartz reaction chamber or a high-purity graphite reaction chamber);

[0036] (2) Vacuumize the reaction chamber, and then feed argon into the reaction chamber at a flow rate of 10000-13000ml / min, and ensure that the vacuum in the reaction chamber is greater than or equal to 4Pa and less than or equal to 13.3Pa;

[0037] (3) Feed high-purity chlorine gas into the reaction chamber, the feed rate of high-purity chlorine gas is 200-240ml / min, react under the condition of 900-1050°C, high-purity chlorine gas and medical pure tantalum generate tantalum pentachloride gas.

[0038] The invention provides a method for preparing a medical porous tantalum trabecular shell by chemical vapor deposition, which specifically includes the following steps:

[0039] The temp...

preparation example

[0042] A kind of tantalum pentachloride gas is prepared as follows:

[0043] (1) Put medical pure tantalum in the quartz reaction chamber;

[0044] (2) Vacuumize the quartz reaction chamber, then feed argon gas into the quartz reaction chamber, the flow rate of feeding argon gas is 10000ml / min, and make the vacuum degree in the quartz reaction chamber be 10Pa;

[0045] (3) Feed high-purity chlorine gas into the quartz reaction chamber, the feed rate of high-purity chlorine gas is 240ml / min, fully react under the condition of 1050 ℃, can make tantalum pentachloride gas.

Embodiment 1

[0048] Porous tantalum trabecular shells were prepared as follows:

[0049] The temperature in the high-purity graphite reaction chamber is 900°C and the vacuum degree is 4Pa; the porous carbon substrate is placed in the high-purity graphite reaction chamber; the tantalum pentachloride gas is passed into the high-purity In the graphite reaction chamber, at the same time, high-purity hydrogen gas is passed into the high-purity graphite reaction chamber at a rate of 530ml / min, and reacted for 9 hours. The tantalum metal will be deposited on the surface of the porous carbon substrate to produce Porous tantalum trabecular shell.

[0050] A tibial prosthesis was prepared as follows:

[0051] Firstly, the surface of the titanium alloy tibial plateau was pretreated to make its smoothness reach 0.2; then, the porous tantalum trabecular shell prepared above and the surface pretreated titanium alloy tibial plateau were placed in an argon protective atmosphere by diffusion welding Weld...

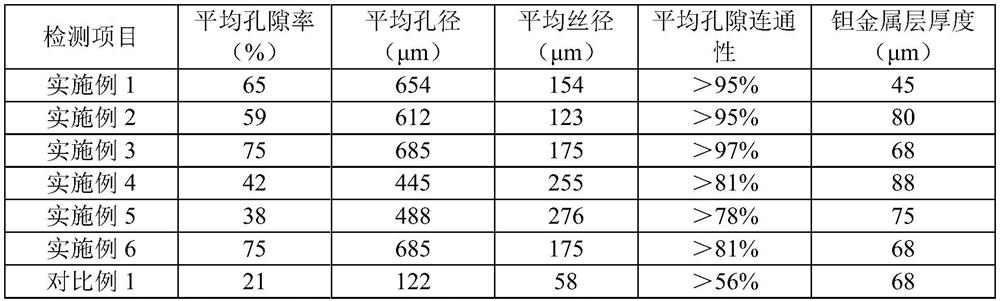

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com