A kind of ternary cathode material coated with organic double layer and its preparation and application

A positive electrode material, double-layer coating technology, applied in the field of lithium-ion battery electrode material preparation, can solve problems such as damage, not conducive to improving the rate performance of particle materials, poor ion/electronic conductivity of inorganic coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

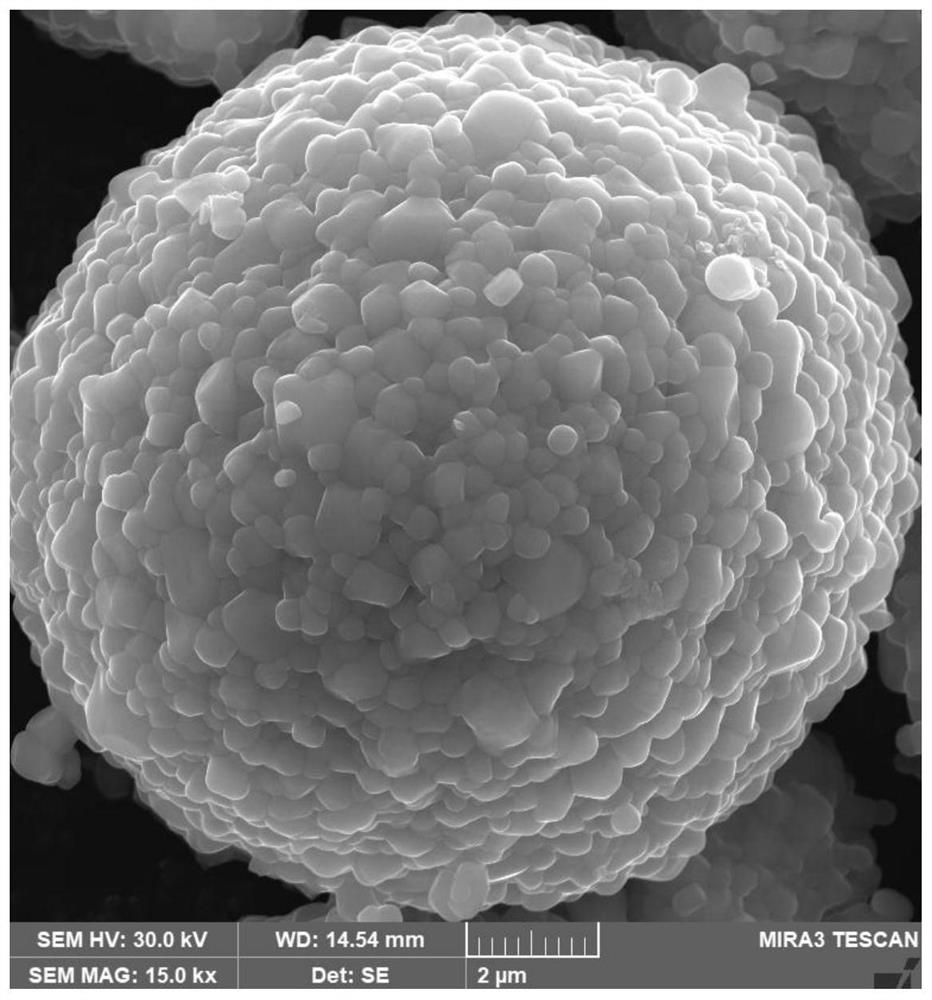

[0051] Accurately weigh 0.05g of polyacrylic acid, 10g of lithium nickel cobalt aluminate (LiNi 0.8 co 0.15 Al 0.05 o 2 ) was dissolved in 10mL isopropanol, stirred for 2 hours to obtain mixed solution A, 2mL water, 0.05g KH550 and 0.05g polyacrylic acid were sealed and stirred in a water bath at 60°C for 2 hours to obtain solution B, and then added solution B to solution A Stirring was continued for 3 hours. The obtained liquid was placed in an oven at 100° C. for 12 hours to evaporate the isopropanol and water to dryness, and a rigid-flexible blend polymer-coated ternary material with a coating amount of 1.5 wt % was obtained.

[0052] Weigh 0.32g rigid-flexible blend polymer-coated ternary material sample, add 0.04g conductive carbon black and 0.04g PVDF, mix and grind manually in an agate mortar for 20min, add appropriate amount of NMP, and prepare a slurry with a certain viscosity. Coat the prepared slurry on an aluminum foil with a thickness of 18 μm, dry it under va...

Embodiment 2

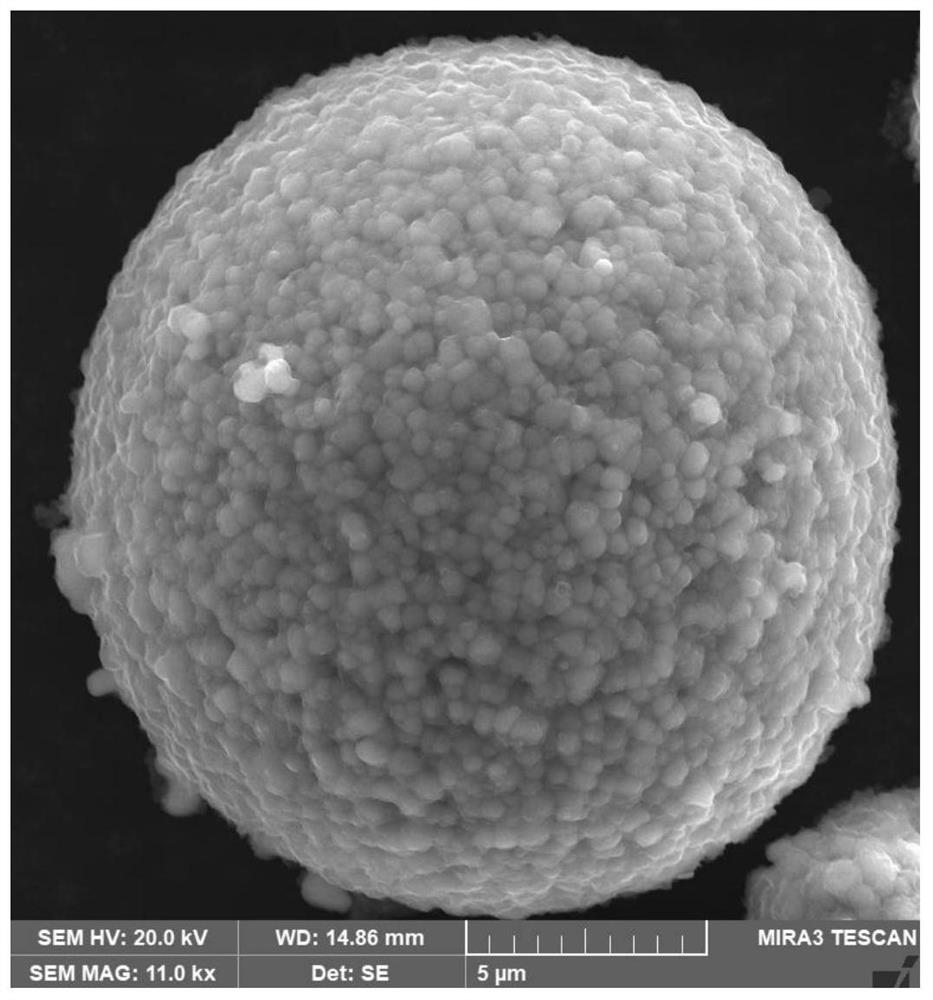

[0054] Accurately weigh 0.05g of alginic acid, 10g of lithium nickel cobalt aluminate (LiNi 0.8 co 0.15 Al 0.05 o 2 ) was dissolved in 10mL isopropanol, stirred for 2 hours to obtain mixed solution A, 2mL water, 0.05g KHT-103 and 0.05g alginic acid were sealed and stirred in a water bath at 60°C for 2 hours to obtain solution B, and then added to Solution A was stirred continuously for 3 hours. The resulting liquid was placed in an oven at 100° C. for 12 hours to evaporate the isopropanol and water to dryness to obtain a rigid-flexible blend polymer-coated ternary material with a coating amount of 1.5 wt%.

[0055] Weigh 0.3200g rigid-flexible blend polymer-coated ternary material sample, add 0.04g conductive carbon black and 0.04g PVDF, mix and grind manually in an agate mortar for 20min, add appropriate amount of NMP, and prepare a slurry with a certain viscosity. Coat the prepared slurry on an aluminum foil with a thickness of 18 μm, dry it under vacuum at 120 ° C, and ...

Embodiment 3

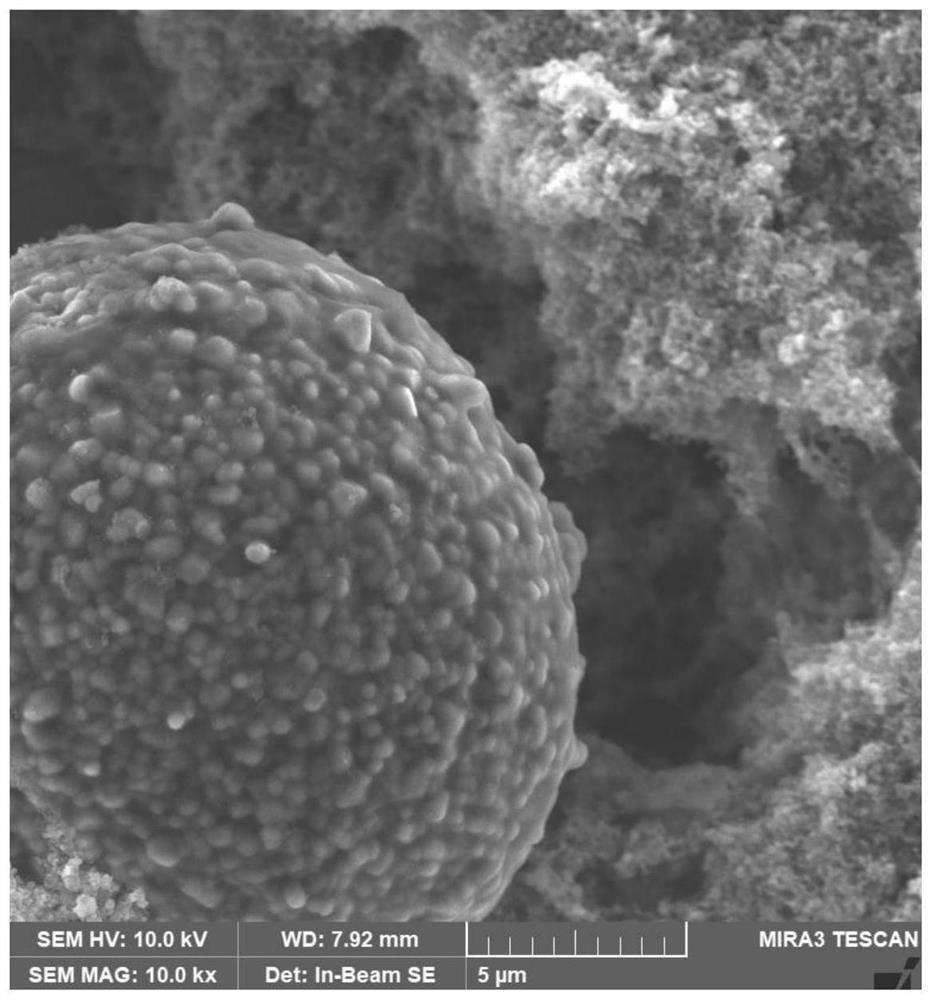

[0057] Accurately weigh 0.05g of alginic acid, 10g of lithium nickel cobalt aluminate (LiNi 0.8 co 0.15 Al 0.05 o 2 ) was dissolved in 10mL isopropanol, stirred for 2 hours to obtain mixed solution A, 2mL water, 0.05g KH570 and 0.05g alginic acid were sealed and stirred in a water bath at 60°C for 2 hours to obtain solution B, and then added solution B to solution A Stirring was continued for 3 hours. The resulting liquid was placed in an oven at 100° C. for 12 hours to evaporate the isopropanol and water to dryness to obtain a rigid-flexible blend polymer-coated ternary material with a coating amount of 1.5 wt%.

[0058] Weigh 0.32g rigid-flexible blend polymer-coated ternary material sample, add 0.04g conductive carbon black and 0.04g PVDF, mix and grind manually in an agate mortar for 20min, add appropriate amount of NMP, and prepare a slurry with a certain viscosity. Coat the prepared slurry on an aluminum foil with a thickness of 18 μm, dry it under vacuum at 120 ° C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com