Composite for cathode of Li-ion battery, preparation process thereof, cathode of Li-ion battery, and Li-ion battery

A lithium-ion battery, composite material technology, applied in electrode manufacturing, battery electrodes, secondary batteries and other directions, can solve the problems of poor cycle stability, loss, low battery capacity, etc., to achieve good high voltage stability, high voltage capacity, The effect of long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The second aspect of the present invention provides a method for preparing a composite material for lithium-ion battery cathodes, the method comprising: mixing the first component and the second component in proportion to obtain the composite material;

[0034] Wherein, the first component is an active material or a surface-treated active material, and the active material is composed of the general formula Li1+a (Ni 1-b-c co b mn c )O 2 Indicates that 0≤a≤0.5, 0≤b≤0.4, 0≤c≤0.6, and b+c0.5 mn 1.5 o 2 express;

[0035] The amount of the second component is 1-30% by weight of the total amount of the composite material.

[0036] In some embodiments of the present invention, preferably, the amount of the second component is 5-25% by weight of the total amount of the composite material.

[0037] In some embodiments of the present invention, preferably, based on the total amount of the composite material, the content of the first component is 70-99% by weight, more prefe...

Embodiment 1

[0069] Composites with different weight percentages of HVS and NCM111.

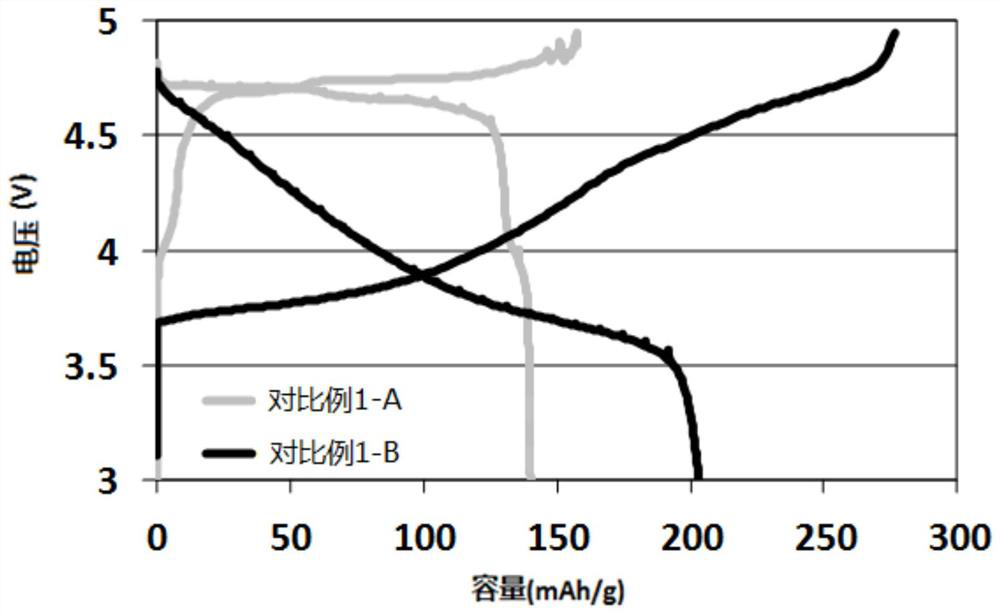

[0070] Add 0.53g of acetylene black and 0.21g of graphite into the polyvinylidene fluoride binder solution (the concentration of polyvinylidene fluoride is 10% by weight), and stir with a stirrer for 30min, then follow the LiNi 0.5 mn 1.5 o 2 (HVS), Li 1+a (Ni 1-b- c co b mn c )O 2 (a=0, b=c=1 / 3, NCM111) these powder components are sequentially added to the above solution and stirred with a stirrer for 1-2 hours to form a slurry, wherein the amount of HVS and NCM111 is as follows 1. The slurry was coated on an aluminum foil current collector using an experimental coater, and dried at 85° C. for 2 h to form a cathode material layer on the current collector, thereby obtaining a cathode. The cathode prepared above, the Celgard porous polyolefin separator, the metal lithium anode, and 1.2mol / L LiPF 6 EC / DEC (3:7 by weight) electrolyte was assembled into a CR2032 button cell.

[0071] Among them, th...

Embodiment 2

[0088] It was prepared by the same method as in Example 1-A, except that 5 wt% HVS-95 wt% NCM111 was replaced by 10 wt% HVS-90 wt% TR-NCM111.

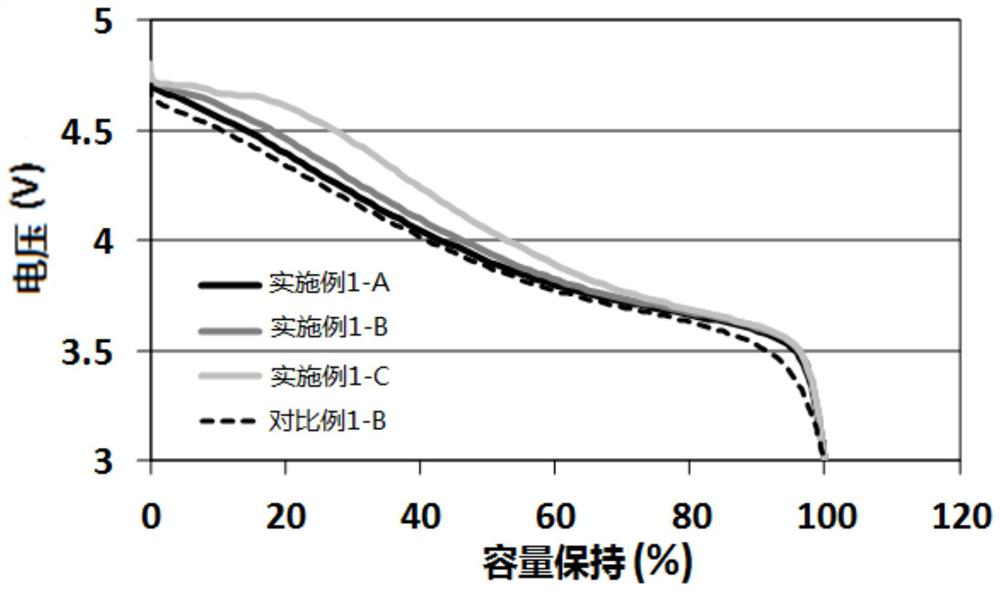

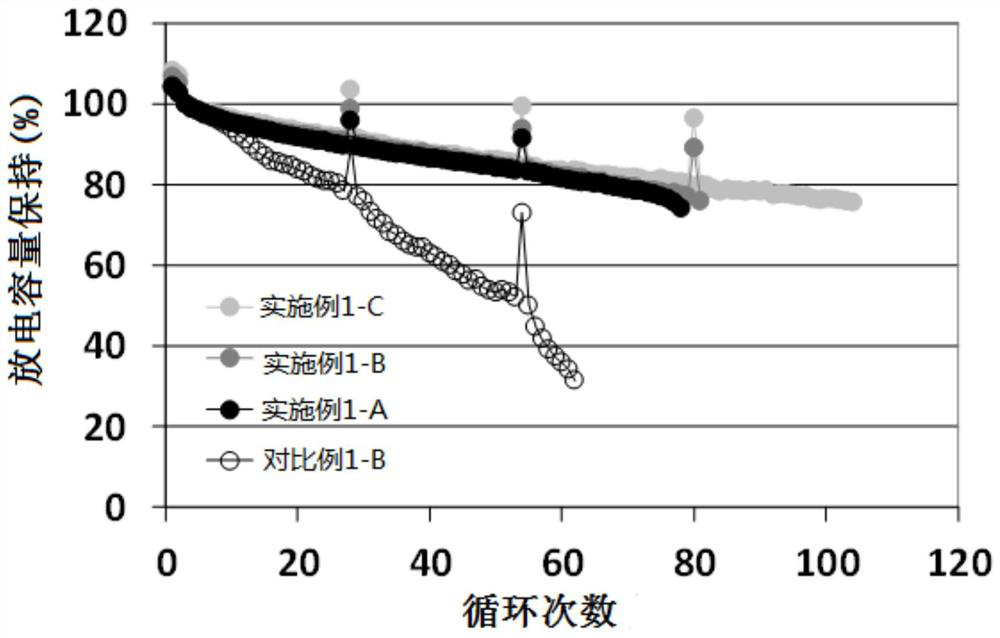

[0089] Using a 10mA LAND battery test system at 30°C with a constant current in the voltage range of 2V to 4.6V, the first two cycles use a low rate C / 15, and then change from the third cycle to a C / 7 rate cycle pair The button battery is tested for discharge capacity retention and cycle times, and the test results are as follows: Figure 4 shown.

[0090] Figure 4 In order to use the composite material with HVS of 10% by weight and NCM111 of 90% by weight, the composite material of TR-NCM111 with 10% by weight of HVS and 90% by weight, and pure Curves of discharge capacity retention (2V-4.6V) and cycle times of batteries prepared with NCM111 and pure TR-NCM111 respectively. This figure shows that the two-component mixture used in the present invention has better high voltage capacity retention compared with a single component, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com