Composite solid electrolyte and preparation method thereof

A solid electrolyte, a certain amount of technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve problems such as narrow electrochemical stability window, low room temperature ionic conductivity, low density, strong salt dissociation ability, etc. Achieve the effects of eliminating ion transport resistance, enhancing high voltage stability, and wide electrochemical stability window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

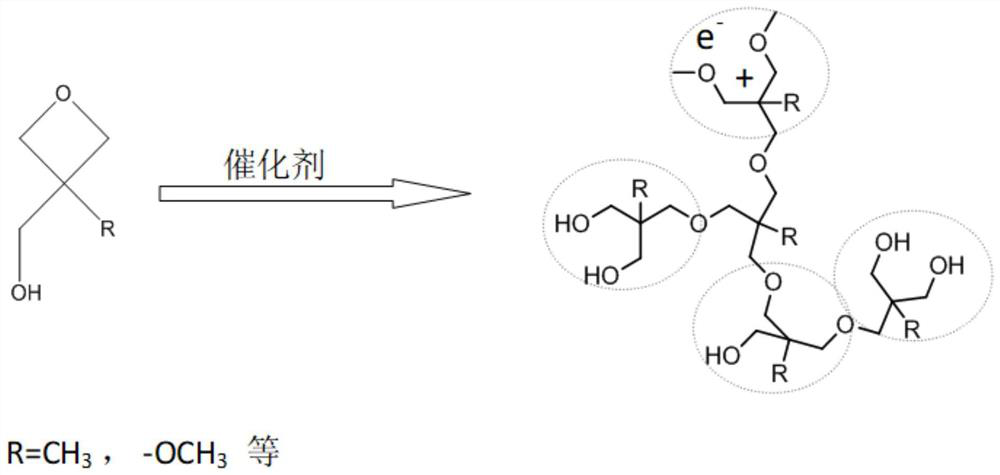

[0036] S1: Mix 15 parts by volume of boron trifluoride ether with 25 parts by volume of dichloromethane to obtain a mixed solution, heat the mixed solution to 35°C, and then add 25 parts by volume of 3-methyl-3 -Hydroxymethyloxetane, and then react at a constant temperature at 35°C for 25h to obtain solution A;

[0037] S2: adding solution A dropwise to ice water for precipitation, filtering, and freeze-drying the filter residue to obtain hyperbranched ether polymer particles;

[0038] S3: Dissolve 7.5 parts by mass of hyperbranched ether polymer particles in 100 parts by mass of N,N-dimethylformamide to obtain solution B, and dissolve 7.5 parts by mass of PVDF-HFP in 100 parts by mass of N,N- - in dimethylformamide, solution C is obtained;

[0039] S4: After mixing 30 parts by mass of solution B and 40 parts by mass of solution C, add 2.5 parts by mass of LiTFSI, mix evenly to obtain a slurry, and coat the slurry on both sides of a PP diaphragm with a thickness of 5 μm (one-...

Embodiment 2

[0042] S1: Mix 10 parts by volume of oxalic acid and 20 parts by volume of propane to obtain a mixed solution, heat the mixed solution to 50°C, and then add 20 parts by volume of 3-ethyl-3-hydroxymethyloxaphrine dropwise to the mixed solution Cyclobutane, and then react at a constant temperature of 50°C for 20h to obtain solution A;

[0043] S2: adding the solution A dropwise into ice water for precipitation, filtering, and freeze-drying the filter residue to obtain hyperbranched ether polymer particles;

[0044] S3: Dissolving 5 parts by mass of hyperbranched ether polymer particles in 100 parts by mass of N,N-dimethylformamide to obtain solution B, dissolving 10 parts by mass of PPSU in 100 parts by mass of N,N-dimethylformamide In base formamide, solution C is obtained;

[0045] S4: After mixing 20 parts by mass of solution B and 50 parts by mass of solution C, add 3.5 parts by mass of LiPF 6 , mixed evenly to obtain a slurry, the slurry was coated on both sides of a 5 μm...

Embodiment 3

[0047] S1: Mix 13 parts by volume of stannous oxalate and 10 parts by volume of n-hexane to obtain a mixed solution, heat the mixed solution to 25°C, and then add 30 parts by volume of 3,3-bismethylol- 1-Oxetane, and then react at a constant temperature at 25°C for 30h to obtain solution A;

[0048] S2: adding the solution A dropwise into ice water for precipitation, filtering, and freeze-drying the filter residue to obtain hyperbranched ether polymer particles;

[0049] S3: Dissolve 10 parts by mass of hyperbranched ether polymer particles in 100 parts by mass of N,N-dimethylformamide to obtain solution B, and dissolve 5 parts by mass of PVDF-HFP in 100 parts by mass of N,N- In dimethylformamide, solution C is obtained;

[0050] S4: After mixing 40 parts by mass of solution B and 40 parts by mass of solution C, add 1.0 parts by mass of LiBF 4 , mixed evenly to obtain a slurry, the slurry was coated on both sides of a 5 μm pp separator (one-side coating thickness 8 μm), and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com