Powder material and machining method for metal injection molding

A metal powder, injection molding technology, used in metal processing equipment, transportation and packaging, etc., can solve the problems of low efficiency of CNC processing methods, unable to meet environmental protection requirements, difficult to produce circulators, etc., to increase corrosion resistance and ductility. , The effect of improving product organization, increasing density and static particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

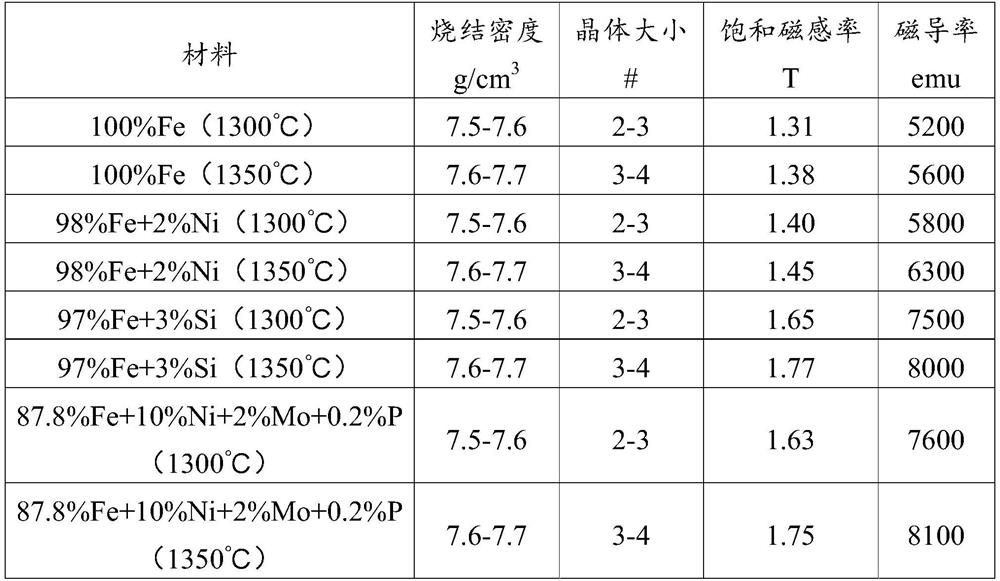

[0055] Select a nearly spherical iron powder with powder particle size D90<15μm, C content<0.05%, O content<3500ppm, and configure metal powder according to the weight ratio of 87.8% Fe, 10% Ni, 2% Mo and 0.2% P.

[0056] Add binder (5% EVA, 6% HDPE, 3% stearic acid, 1% antioxidant, 85% POM (polyoxymethylene) to the metal powder at a weight ratio of 9:1, of which the antioxidant is B900) , uniformly granulated through a honey mixer to obtain metal powder injection feed.

[0057] Put the granulated metal powder injection feed into the metal powder injection molding machine, inject the metal powder feed into the mold cavity under the conditions of mold temperature 100°C, material temperature 185°C, and injection pressure 60MPa, and then hold the pressure for 2s , cooled for 5s to obtain a green body.

[0058] Put the green body into the degreasing furnace for degreasing. During the degreasing process, the amount of nitric acid added is 2ml / min, and nitrogen gas is filled at 80L...

Embodiment 2

[0066] Select a nearly spherical iron powder with powder particle size D90<15μm, C content<0.05%, O content<3500ppm, and configure metal powder according to the weight ratio of 87.8% Fe, 10% Ni, 2% Mo and 0.2% P.

[0067] Add binder (EVA 5%, HDPE 6%, stearic acid 3%, antioxidant 1%, POM 85% in metal powder with the weight ratio of 9:1, wherein, antioxidant is antioxidant 1010), Uniform granulation through honey mixer to obtain metal powder injection feed.

[0068] Put the granulated metal powder injection feed into the metal powder injection molding machine, inject the metal powder feed into the mold cavity under the conditions of mold temperature 120°C, material temperature 190°C, and injection pressure 100MPa, and then hold the pressure for 3s , cooled for 8s to obtain a green body.

[0069] Put the green body into the degreasing furnace for degreasing. During the degreasing process, the amount of nitric acid added is 3ml / min, and nitrogen gas is filled at 85L / min for flush...

Embodiment 3

[0077] Select a nearly spherical iron powder with powder particle size D90<15μm, C content<0.05%, O content<3500ppm, and configure metal powder according to the weight ratio of 87.8% Fe, 10% Ni, 2% Mo and 0.2% P.

[0078] Add binder (EVA 5%, HDPE 6%, stearic acid 3%, antioxidant 1%, POM 85% to metal powder with the weight ratio of 9:1, wherein, antioxidant is BHT), through honey smelting Machine uniform granulation to obtain metal powder injection feeding.

[0079] Put the granulated metal powder injection feed into the metal powder injection molding machine, inject the metal powder feed into the mold cavity under the conditions of mold temperature 125°C, material temperature 200°C, and injection pressure 150MPa, and then hold the pressure for 4s , cooled for 15s to obtain a green body.

[0080] Put the green body into the degreasing furnace for degreasing. During the degreasing process, the amount of nitric acid added is 4ml / min, and nitrogen gas is filled at 80L / min for was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com