Retreatment method of recycled carbon fibers

A carbon fiber recycling and reprocessing technology, applied in fiber treatment, ultrasonic/sonic fiber treatment, physical treatment, etc., can solve the problems of limiting the comprehensive performance of composite materials, difficult to ensure the stability of quality, disordered fiber shape, etc., to achieve expanded reuse Fields, improved thermal conductivity, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

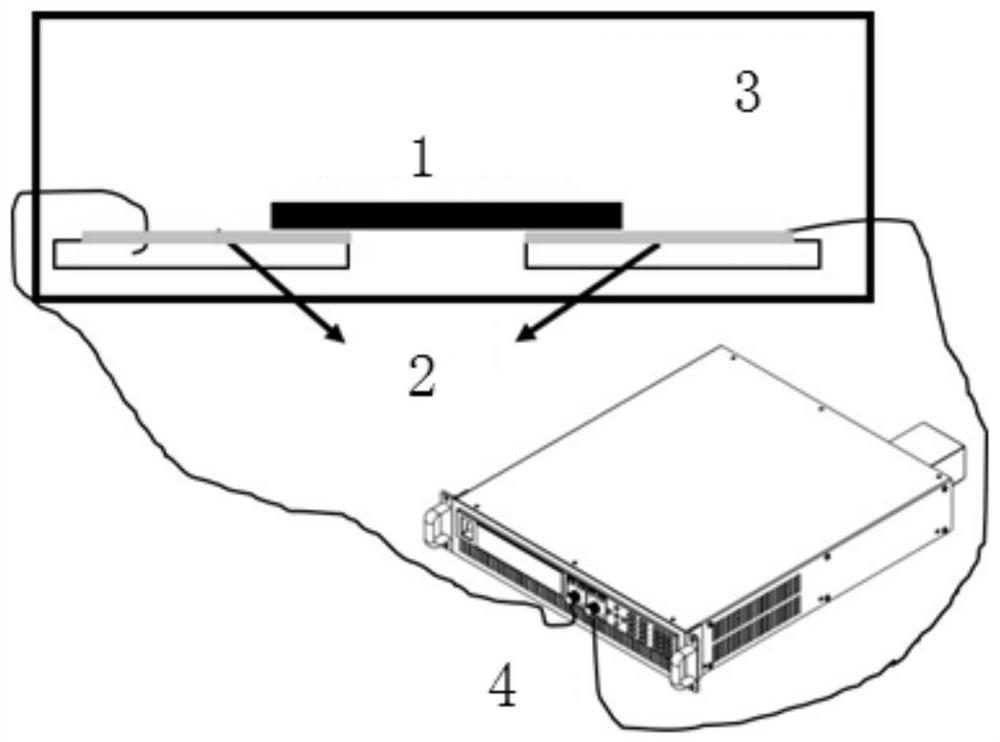

Image

Examples

Embodiment 1

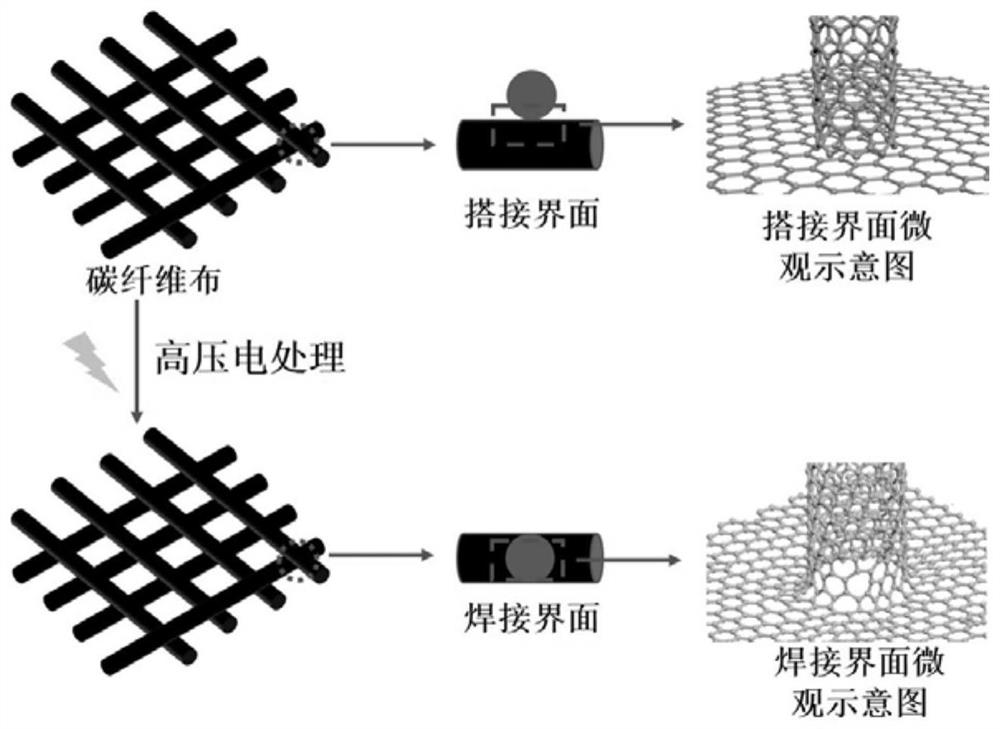

[0029] The bidirectional carbon fiber cloth recovered by pyrolysis was ultrasonically cleaned with ethanol for 1 h. Then the cleaned carbon fiber cloth was placed in a vacuum oven at 60°C and dried for 12 hours. Then the recycled carbon fiber cloth is non-woven and cut into rectangular pieces of 10cm×5cm for later use. Using conductive silver paste, two copper sheet electrodes with a size of 4cm×5cm were bonded to both sides of the cut recycled carbon fiber cloth, placed in a vacuum oven at 70°C, and dried for 3 hours. The dried sample was transferred to a closed box with an argon protective atmosphere, and the positive and negative poles of the regulated DC power supply were connected to the copper sheet electrodes. Use a voltage of 150V to conduct electricity treatment on carbon fiber cloth, and the voltage density is 3V / cm 2 , the power-on time is 1min. After energizing, take out the sample, remove the copper electrode lugs at both ends, use acetone to clean the carbon f...

Embodiment 2

[0032] Ultrasonic cleaning is performed on the carbon fiber precursors obtained by the method of supercritical dissolution of thermosetting composite materials, and the cleaning time is 1 h. Then the cleaned carbon fiber cloth was placed in a vacuum oven at 60°C and dried for 12 hours. Then the recycled carbon fiber cloth is non-woven and cut into 8cm×6cm rectangular pieces for later use. Two pieces of copper foil with a size of 6 cm × 5 cm were bonded on both sides of the cut recycled carbon fiber cloth with conductive adhesive IAC, and placed in a vacuum oven at 70 ° C for 3 h. The dried sample was transferred to a closed box with an argon protective atmosphere, and the positive and negative electrodes of the regulated DC power supply were connected to the copper foil. Use a voltage of 120V to conduct electricity treatment on carbon fiber cloth, and the voltage density is 2.5V / cm 2 , power-on time is 3min. After electrification, take out the sample, remove the copper foil...

Embodiment 3

[0035] During high voltage treatment, the applied voltage density is 1V / cm 2 , the processing time is 300s. All the other are with embodiment 1.

[0036] The carbon fiber cloth before and after electrification treatment was used as reinforcement, and thermosetting resin-based composite materials were prepared respectively. Bisphenol A epoxy resin (E-51) was used as the resin matrix, methyl nadic anhydride was used as the curing agent, and tertiary amine salt was used as the curing agent. Accelerator, mixed uniformly at room temperature, wherein the mass ratio of resin, curing agent and accelerator is 100:98.5:4. The vacuum-assisted molding process is used for molding, and the curing system is 100°C for 1h+130°C for 4h to obtain a carbon fiber reinforced composite material. After mechanical testing, the composite material made of carbon fiber before treatment has a tensile strength of 377.4MPa and a bending strength of 449.3MPa; while the composite material made of carbon fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com