Shaping Color Pavement Coatings

A color and coating technology, applied in the field of shaping color pavement coatings, can solve the problems of inability to combine the advantages of inorganic and organic anti-slip materials, short impact resistance construction period, etc., to achieve good adhesion fastness and increase adhesion fastness. , the effect of good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0066] Embodiments 1-6 all relate to a kind of shaping colored road paint, including component A, component B and component C.

[0067] The raw material ratio of component A is shown in Table 2.

[0068] Table 2. Raw material ratio table of component A in embodiment 1-6 (by mass percentage)

[0069]

[0070] Weigh the raw materials according to the ratio in Table 2, stir and mix evenly to obtain component A.

[0071] The component B raw material ratio (by mass percentage) of embodiment 1-6 is identical, specifically:

[0072] AEH-2014 Environment-friendly Floor Coating Emulsion 90wt%

[0073] BYK022 1wt%

[0074] Hytrel G5544 (Shore hardness 55D) 9wt%;

[0075] Weigh AEH-2014 environment-friendly floor paint emulsion, BYK022 and Hytrel G5544 (Shore hardness 55D) according to the proportion, stir and mix evenly to obtain component B.

[0076] The raw material ratio (by mass percentage) of the component C of embodiment 1-6 is identical, specifically:

[0077] CIMENT FON...

Embodiment 7-8

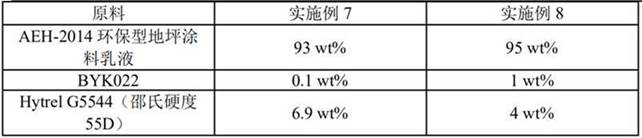

[0089] Examples 7-8 are all based on Example 4, and the only difference from Example 4 is the raw material ratio of component B, as shown in Table 3.

[0090] Table 3. Raw material ratio table of component B in embodiment 7-8 (by mass percentage)

[0091]

[0092] Weigh the raw materials according to the ratio in Table 3, and mix them evenly to obtain Component B. In other embodiments, the AEH-2014 environment-friendly floor coating emulsion can also be replaced by other commercially available commercial emulsions such as DOW MAINCOTE AEH-20 water-based acrylic epoxy hybrid emulsion or self-made acrylic epoxy hybrid emulsion; as a toughening agent The added Hytrel G5544 (Shore hardness 55D) can also be replaced by acrylonitrile rubber particles and TPU particles, but the effect is slightly worse than that of thermoplastic polyester elastomer (TPEE).

Embodiment 9-12

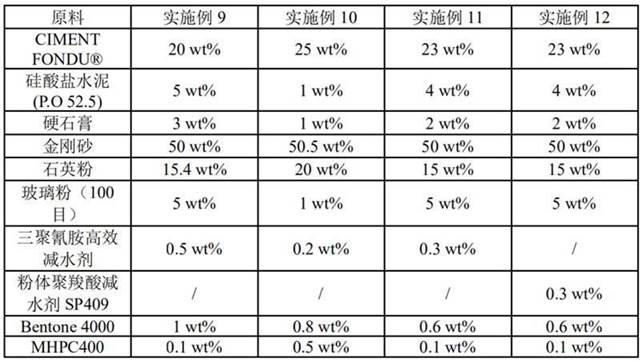

[0094] Examples 9-12 are all based on Example 7, and differ from Example 7 only in that the raw material ratio of component C is different, see Table 4 for details.

[0095] Table 4. Raw material ratio table of component C in embodiment 9-12 (by mass percentage)

[0096]

[0097] The mesh numbers of emery used in Examples 9-12 are 80 mesh, 70 mesh, 60 mesh, and 60 mesh in turn; the mesh numbers of quartz powder used in Embodiment 9-12 are 120 mesh, 80 mesh, 100 mesh, and 100 mesh in turn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com