Polyurethane adhesive with three-dimensional structure and preparation method thereof

A polyurethane adhesive, three-dimensional structure technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of insufficient bonding performance of adhesives, low shear strength of adhesives, etc., and achieves short synthesis time. The synthesis conditions are mild and controllable, and the production operability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

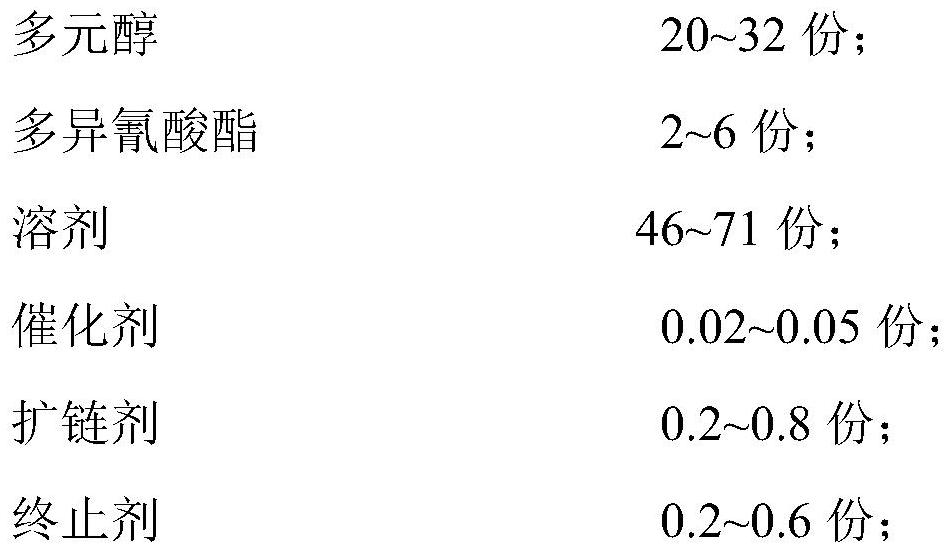

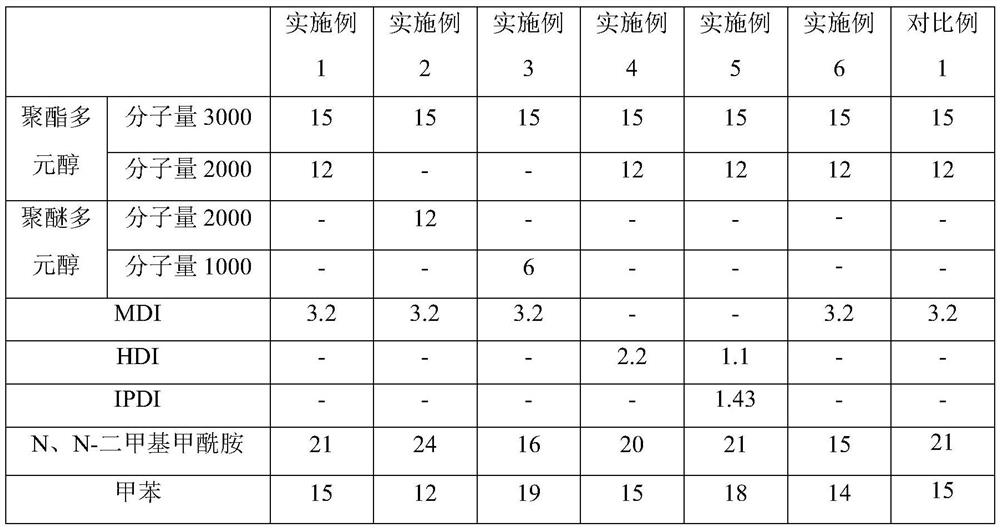

[0042] The polyurethane adhesive with three-dimensional structure provided in this example includes polyol, polyisocyanate, solvent, catalyst, chain extender, terminator, viscosity modifier and cellosolve, and the contents of each component are shown in Table 1.

[0043] in,

[0044] The polyester polyol adopting molecular weight is the polyester polyol of 3000 (from Asahikawa Chemical Company, the trade mark is SH3000B) and the polyester polyol with molecular weight of 2000 (from Asahikawa Chemical Company, the trade mark is SH2000B);

[0045] Polyisocyanate adopts MDI;

[0046] Solvents include N,N-dimethylformamide, toluene, dimethyl carbonate;

[0047] The catalyst adopts stannous octoate;

[0048] Chain extenders include ethylene glycol, 1,4-butanediol, and trimethylolpropane;

[0049] Terminators use ethylene glycol and isopropanol.

[0050] Viscosity modifier adopts acetone;

[0051] Cellosolve uses ethylene glycol monomethyl ether.

[0052] The preparation method...

Embodiment 2

[0060] The difference between Example 2 and Example 1 is that the polyols include polyester polyols with a molecular weight of 3000 and polyether polyols with a molecular weight of 2000 (sourced from China Taiwan Dalian Company, brand name PTMG2000). In this example, the content of each component is shown in Table 1.

Embodiment 3

[0062] The difference between Example 3 and Example 1 is that the polyols include polyester polyols with a molecular weight of 3000 and polyether polyols with a molecular weight of 1000 (sourced from Taiwan Dalian Company, trade name PTMG1000). In this example, the content of each component is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com