Method for preparing Al-Cr composite coating through laser cladding

A technology of laser cladding and composite coating, which is applied in coating, metal material coating process, etc., can solve the problems of laser cladding technology application difficulty, difficult laser rapid prototyping, large thermal expansion coefficient, etc., and reduce cracking sensitivity , Realize the automation of industrial production and increase the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A preferred embodiment of the present invention provides a method for preparing an Al-Cr composite coating by laser cladding, the specific steps are as follows:

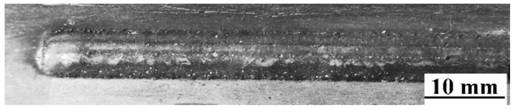

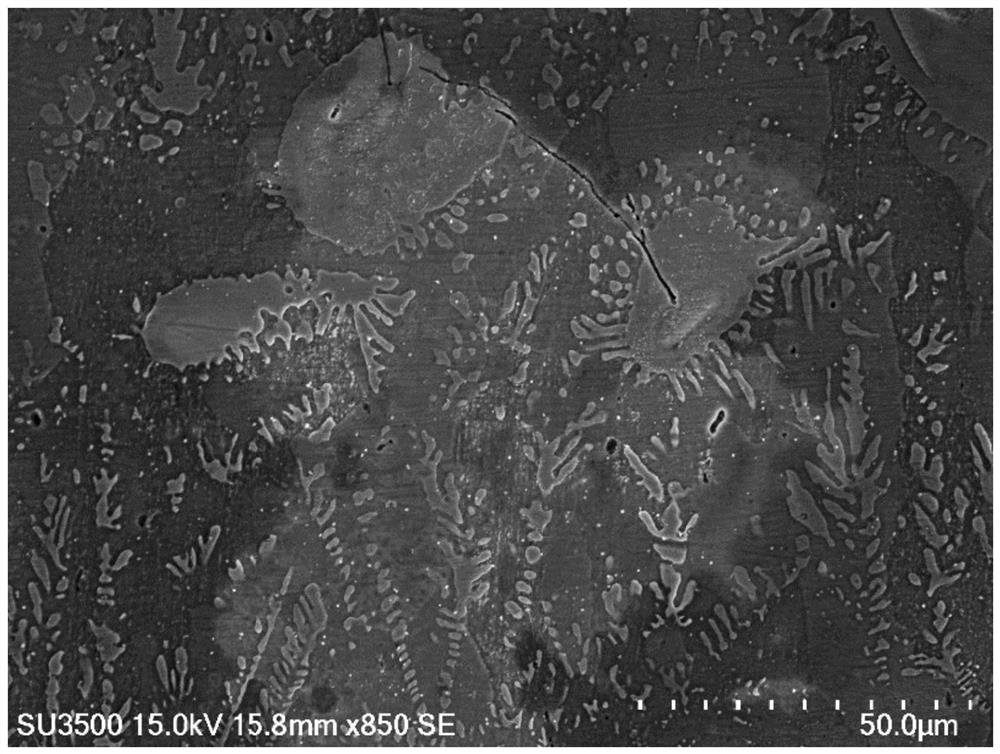

[0048] Put Al powder with a purity ≥ 99.0% and a particle size of 58 μm and Cr powder with a purity ≥ 99.0% and a particle size of 45 μm in the proportion of 50% of the mass of the Cr powder to the mass of the Al powder, and mix for 2 hours , where the forward and reverse interval time is 1min, the rotation speed is 100rpm, wrapped with aluminum foil, and placed in a drying oven at 40°C for 30min. Use 400 and 800 mesh sandpaper to grind off the oxide layer on the surface of the 7075 aluminum alloy plate in turn, then clean it with ultrasonic waves for 5 minutes, and dry it with a hair dryer. The surface is then sandblasted to increase the absorption of the laser light. The method of laser cladding is used to clad Al-Cr composite coating on the surface of 7075 aluminum alloy plate. The laser power is 1.7kW, t...

Embodiment 2

[0050] A preferred embodiment of the present invention provides a method for preparing an Al-Cr composite coating by laser cladding, the specific steps are as follows:

[0051] Put the Al powder with a purity ≥ 99.0% and a particle size of 58 μm and the Cr powder with a purity ≥ 99.0% and a particle size of 45 μm in the proportion of 30% of the mass of the Cr powder to the mass of the Al powder, and mix them for 2 hours , where the forward and reverse interval time is 1min, the rotation speed is 100rpm, wrapped with aluminum foil, and placed in a drying oven at 40°C for 30min. Use 400 and 800 mesh sandpaper to grind off the oxide layer on the surface of the 7075 aluminum alloy plate in turn, then clean it with ultrasonic waves for 5 minutes, and dry it with a hair dryer. The surface is then sandblasted to increase the absorption of the laser light. The method of laser cladding is used to clad Al-Cr composite coating on the surface of 7075 aluminum alloy plate. The laser powe...

Embodiment 3

[0053] A preferred embodiment of the present invention provides a method for preparing an Al-Cr composite coating by laser cladding, the specific steps are as follows:

[0054] Put Al powder with a purity ≥ 99.0% and a particle size of 58 μm and Cr powder with a purity ≥ 99.0% and a particle size of 45 μm in the proportion of 40% of the mass of the Cr powder to the mass of the Al powder, and mix for 2 hours , where the forward and reverse interval time is 1min, the rotation speed is 100rpm, wrapped with aluminum foil, and placed in a drying oven at 40°C for 30min. Use 400 and 800 mesh sandpaper to grind off the oxide layer on the surface of the 7075 aluminum alloy plate in turn, then clean it with ultrasonic waves for 5 minutes, and dry it with a hair dryer. The surface is then sandblasted to increase the absorption of the laser light. The method of laser cladding is used to clad Al-Cr composite coating on the surface of 7075 aluminum alloy plate. The laser power is 1.7kW, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com