Toughened abrasion-resistant epoxy resin cement gum and preparation method thereof

A technology of epoxy resin mastic and epoxy resin, which is applied in the direction of epoxy resin coatings and coatings, can solve the problems of brittleness, poor impact resistance, high cross-linking density, poor weather resistance, etc., and achieve strength compensation Loss, improve UV resistance, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

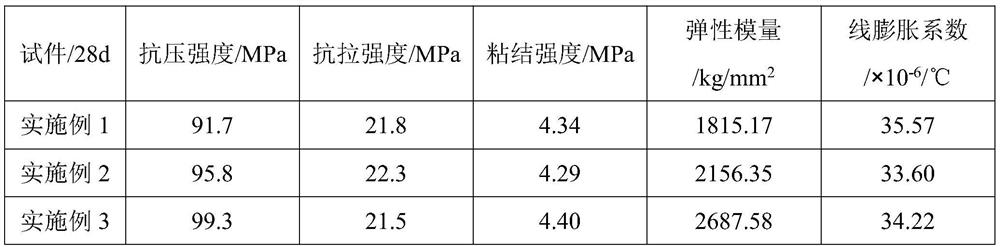

Examples

preparation example Construction

[0042] The embodiment of the present application also relates to a preparation method of the aforementioned toughened anti-abrasion epoxy resin mastic, comprising the following steps:

[0043](1) Mix the epoxy resin, diluent, and active diluent AGE in component A, stir evenly, put it into a three-roller machine, then add fumed silica and nano light calcium bromide, and grind until the fineness is less than 50;

[0044] (2) Mix the curing agent in component B and the DMP-30 accelerator and stir evenly, put it into a three-roll machine, then add nano light calcium bromide and graphene oxide nanosheets, and grind until the fineness is less than 50;

[0045] (3) Mix the mixture prepared in step (1) and step (2) in proportion, and manually stir with a three-roll machine to obtain the cement.

[0046] As a further optimized solution, this application also provides another method for preparing the aforementioned toughened anti-abrasion epoxy resin mastic. Specifically, the modified b...

Embodiment 1

[0055] A toughened anti-abrasion epoxy resin mastic, composed of component A and component B, the ratio of component A to component B is 4:1, component A is composed of the following components by mass: Epoxy resin: 50 parts, 11 parts of diluent, 6 parts of reactive diluent AGE, 5 parts of KH5605, 12 parts of fumed silica, 20 parts of nano light calcium bromide; component B is composed of the following parts by mass: curing agent 70 parts, 12 parts of DMP-30 accelerator, 15 parts of nano light calcium bromide, 3 parts of graphene oxide nanosheets;

[0056] The epoxy resin is composed of a bonding body and a modified body, the bonding body is a bisphenol A type epoxy resin or a bisphenol F type epoxy resin, and the modified body is an epoxy equivalent of 400-900g / mol of epoxy-terminated polysiloxane, the mass ratio of adhesive main body and modified main body is 10:1;

[0057] The curing agent is a composite curing agent composed of polycondensation modified fatty amine adduc...

Embodiment 2

[0064] A toughened anti-abrasion epoxy resin mastic, composed of component A and component B, the ratio of component A to component B is 4:1, component A is composed of the following components by mass: Epoxy resin: 50 parts, 11 parts of diluent, 6 parts of reactive diluent AGE, 5 parts of KH5605, 12 parts of fumed silica, 20 parts of nano light calcium bromide; component B is composed of the following parts by mass: curing agent 70 parts, 12 parts of DMP-30 accelerator, 15 parts of nano light calcium bromide, 3 parts of graphene oxide nanosheets;

[0065] The epoxy resin is composed of a bonding body and a modified body, the bonding body is a bisphenol A type epoxy resin or a bisphenol F type epoxy resin, and the modified body is an epoxy equivalent of 400-900g / mol of epoxy-terminated polysiloxane, the mass ratio of adhesive main body and modified main body is 10:1;

[0066] The curing agent is a composite curing agent composed of polycondensation modified fatty amine adduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com