Marine plastic pipe and preparation method thereof

A technology of plastic pipes and plastic pipe fittings, which is applied in the field of marine plastic pipes and their preparation, and can solve the problems of occupying limited resources of the country, heavy weight, and restricted applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

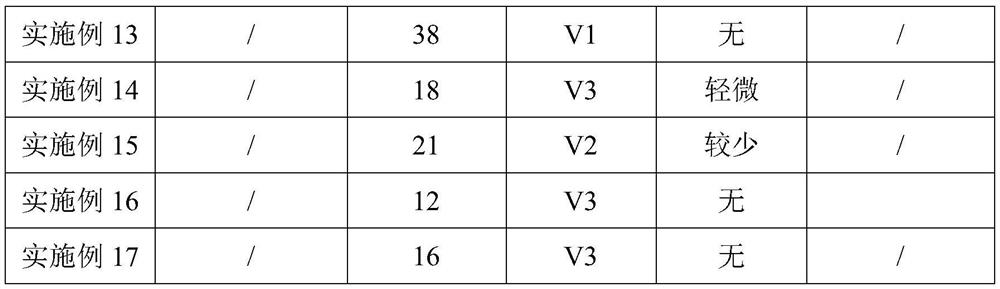

Examples

preparation example Construction

[0073] In the present invention, the preparation method of the polyolefin grafted inorganic filler comprises the following steps:

[0074] (1) The inorganic filler is placed in the plasma generator, and the surface treatment is carried out under the condition that the flow rate of the gas medium is 45-70mL / min and the discharge time is 10-15min;

[0075] (2) Mix the inorganic filler and coupling agent treated in step (1), stir at 50-70°C for 30-80min, then add polyolefin monomer and initiator and mix evenly, and finally extrude through an extruder Granulation for standby, extrusion temperature is 150-300°C.

[0076] In a preferred embodiment, the weight ratio of the inorganic filler, coupling agent, polyolefin monomer and initiator is 100:(1-5):(20-40):(0.01-0.1).

[0077] In a more preferred embodiment, the weight ratio of the inorganic filler, coupling agent, polyolefin monomer and initiator is 100:2:25:0.05.

[0078] In a preferred embodiment, the olefin monomer is a mono...

Embodiment 1

[0131] Example 1 provides a plastic pipe for marine use. The raw materials for the preparation of the plastic pipe include the following components in parts by weight: 81 parts of base resin, 18 parts of filler, 16.2 parts of toughening agent, 1.5 parts of initiator, 8 parts of flame retardant, 2 parts of antioxidant, 2 parts of lubricant.

[0132] The base resin is homopolypropylene, copolypropylene and polybutene with a combined weight ratio of 1:1.2:0.5; the homopolymer polypropylene is selected from ExxonMobil Chemical, ExxonMobil series, model PP2822E2; The polypropylene copolymer is selected from Yanshan Petrochemical, model 4400; the polybutene is selected from Mitsui, Japan, model P5050; the toughening agent is selected from ExxonMobil, EXACT series, model 0203; the initiator It is azobisisobutyronitrile; the antioxidant is 2,6-di-tert-butyl-4-n-butylphenol; the lubricant is polydimethylsiloxane; the filler is polyolefin branch Connected inorganic fillers;

[0133] T...

Embodiment 2

[0144] Embodiment 2 provides a plastic pipe for marine use. The raw materials for the preparation of the plastic pipe include the following components in parts by weight: 50 parts of base resin, 10 parts of filler, 5 parts of toughening agent, 0.1 part of initiator, 1 part of fuel, 0.3 part of antioxidant, 0.2 part of lubricant.

[0145] The base resin is homopolymerized polypropylene, copolymerized polypropylene and polybutene with a combined weight ratio of 1:0.8:0.3; the homopolymerized polypropylene is selected from ExxonMobil Chemical, ExxonMobil series, model PP2822E2; The polypropylene copolymer is selected from Yanshan Petrochemical, model 4400; the polybutene is selected from Mitsui, Japan, model P5050; the toughening agent is selected from ExxonMobil, EXACT series, model 0203; the initiator It is azobisisobutyronitrile; the antioxidant is 2,6-di-tert-butyl-4-n-butylphenol; the lubricant is polydimethylsiloxane; the filler is polyolefin branch Connected inorganic fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com