Single-component epoxy resin flowing type underfill adhesive and preparation method thereof

An epoxy resin and underfill technology, which is applied in the directions of epoxy resin glue, adhesive, polymer adhesive additives, etc., can solve the problems of unhelpful heat dissipation of electronic components, unable to meet the glue filling effect, and reduced glue fluidity. , to achieve the effect of good adhesion, good thermal conductivity and insulation, and low hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

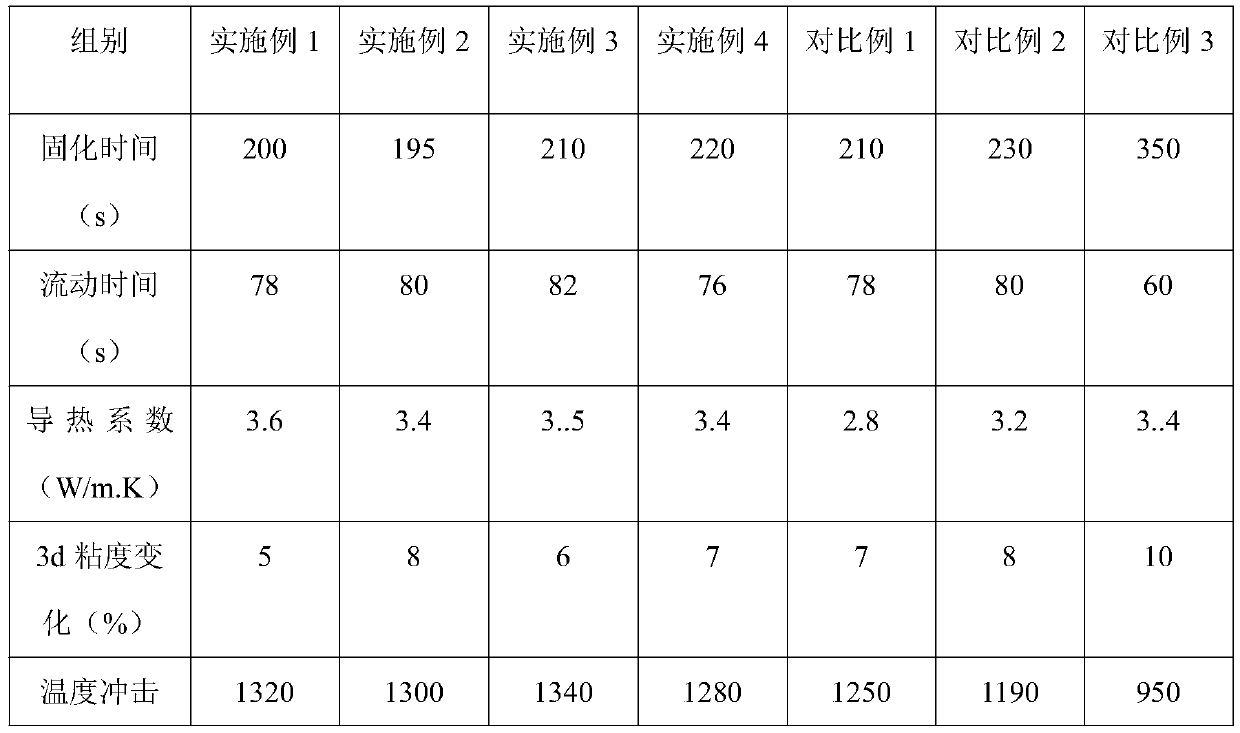

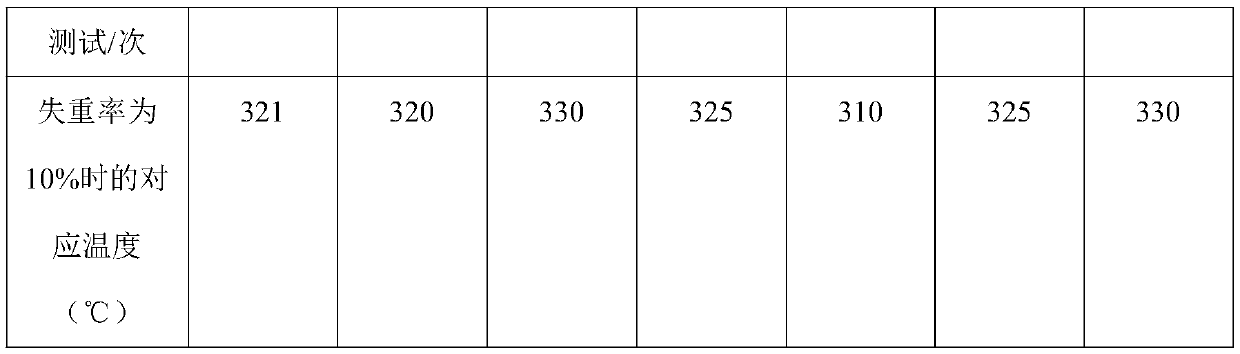

Examples

Embodiment 1

[0026] This embodiment provides a one-component epoxy resin flow type underfill adhesive, including the following components by mass: 40 parts of bisphenol F epoxy resin, 15 parts of the first filler, 8 parts of the second filler, and 8 parts of curing agent , 4 parts of curing accelerator, 10 parts of reactive diluent, 3 parts of toughening agent, 2 parts of ion trapping agent, 2 parts of toner, 0.5 part of coupling agent.

[0027] Wherein, the first filler is spherical silica with a particle size of 15 μm, and the second filler is modified spherical alumina with a particle size of 5 μm. The toughening agent is acrylic rubber with spherical core-shell structure. The structural formula of the ion capture agent is Mg 1-n Al n (OH) 2 (CO 3 ) n / 2 .mH 2O wherein, 0<n≤0.5, the particle size of the ion trapping agent is 2 μm. The reactive diluents are glycidyl methacrylate and butyl glycidyl ether. The curing agent is dicyandiamide curing agent, and the curing accelerator in...

Embodiment 2

[0033] This embodiment provides a one-component epoxy resin flow type underfill adhesive, including the following components by mass: 50 parts of bisphenol F epoxy resin, 10 parts of the first filler, 5 parts of the second filler, and 5 parts of curing agent , 5 parts of curing accelerator, 5 parts of reactive diluent, 3 parts of toughening agent, 0.1 part of ion trapping agent, 3 parts of toner, 3 parts of coupling agent.

[0034] Wherein, the first filler is spherical silica with a particle size of 10 μm, and the second filler is modified spherical alumina with a particle size of 3 μm. The toughening agent is acrylic rubber with spherical core-shell structure. The structural formula of the ion capture agent is Mg 1-n Al n (OH) 2 (CO 3 ) n / 2 .mH 2 O wherein, 0<n≤0.5, the particle size of the ion trapping agent is 3 μm. The reactive diluent is allyl glycidyl ether. The curing agent is a polythiol curing agent, and the curing accelerator is 2-phenyl-4-methyl-5-hydroxyme...

Embodiment 3

[0040] This embodiment provides a one-component epoxy resin flow type underfill adhesive, including the following components by mass: 10 parts of bisphenol F epoxy resin, 20 parts of the first filler, 10 parts of the second filler, and 10 parts of curing agent , 5 parts of curing accelerator, 15 parts of reactive diluent, 3 parts of toughening agent, 3 parts of ion trapping agent, 1 part of toner, and 1 part of coupling agent.

[0041] Wherein, the first filler is spherical silica with a particle size of 25 μm, and the second filler is modified spherical alumina with a particle size of 9 μm. The toughening agent is acrylic rubber with spherical core-shell structure. The structural formula of the ion capture agent is BiO x (OH) y (NO) z , wherein, 0.9≤x≤1.1, 0.6≤y≤0.8, 0.2≤z≤0.4, and the particle size of the ion trapping agent is 0.1 μm. The reactive diluent is n-butyl glycidyl ether. The curing agent is dicyandiamide curing agent, and the curing accelerator is 2-phenyl-4,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com