Quaternary ammonium salt type dendritic polythioether modified polymer microsphere

A dendritic, polysulfide technology, used in biocides, animal repellents, plant growth regulators, etc., can solve problems such as affecting the bactericidal effect, and achieve high bactericidal performance, controllable graft structure, and good stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

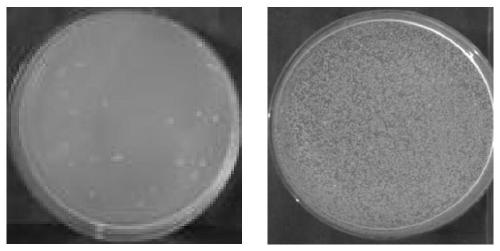

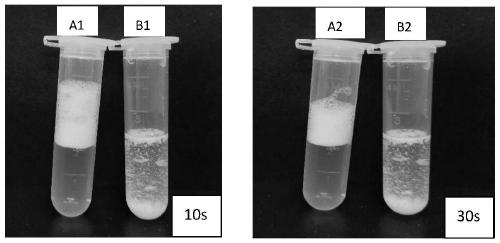

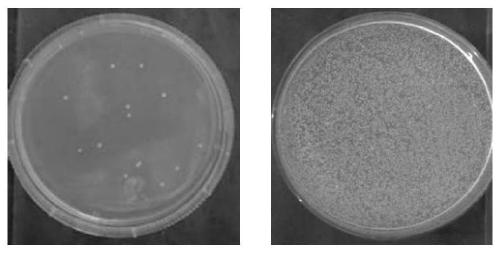

Image

Examples

Embodiment 1

[0051] The preparation method of quaternary ammonium salt type dendritic polysulfide modified polymer microsphere comprises the following steps:

[0052] S1: The mixture of 1,5-pentanedithiol (0.477 g, 3.50 mmol), propargyl glycidyl ether (0.196 g, 1.75 mmol) and 1,7-octadiyne (0.0934 g, 0.875 mmol) was Base material, then add the chloroform of described base material mass 80% (0.613 g), the polyethylene glycol (molecular weight is 5000 g / mol) of described base material mass 25% (0.192 g) and the described base material mass 3% (23 mg) of 2-hydroxy-2-methyl-1-phenyl-1-propanone was stirred into a homogeneous mixture, and the above mixture was slowly added dropwise to a solution with a concentration of 5% sodium dodecylbenzenesulfonate. ionic aqueous solution, then sealed and passed through high-purity nitrogen for 20 minutes, placed in an ice-water mixed bath and irradiated with an ultraviolet lamp for 1 hour until the reaction was completed, then washed and dried to obtain ep...

Embodiment 2

[0062] S1: The mixture of 1,8-octanedithiol (0.571 g, 3.20 mmol), propargyl glycidyl ether (0.269 g, 2.40 mmol) and 1,7-octanediyne (0.043 g, 0.401 mmol) was base material, and then add chloroform of 120% (1.061 g) of the base material mass, polyethylene glycol (molecular weight: 100000 g / mol) of the base material mass 25% (0.221 g) and the base material mass 3% (27 mg) of 1-hydroxycyclohexyl phenyl ketone was stirred into a homogeneous mixture, and the above mixture was slowly added dropwise to a deionized aqueous solution with a concentration of 5% sodium dodecylbenzenesulfonate, and then sealed and ventilated. After entering high-purity nitrogen for 60 minutes, put it in an ice-water mixed bath and irradiate it with an ultraviolet lamp for 3 hours until the reaction is completed, then wash and dry to obtain epoxy-based porous polymer microspheres.

[0063] S2: At room temperature, mix the epoxy-based porous polymer microspheres with propargyl amine according to a mass ratio...

Embodiment 3

[0072] S1: The mixture of 1,3-propanedithiol (0.4534 g, 4.19 mmol), propargyl glycidyl ether (0.283 g, 2.52 mmol) and 1,7-octadiyne (0.052 g, 0.48 mmol) was base material, and then add chloroform of 100% (0.789 g) of the base material mass, polyethylene glycol (molecular weight: 20000 g / mol) of the base material mass 35% (0.276 g) and the base material mass 3% (24 mg) of benzoin dimethyl ether was stirred to form a homogeneous mixture, and the above mixture was slowly added dropwise to a deionized aqueous solution with a concentration of 5% sodium dodecylbenzenesulfonate, then sealed and passed through high-purity nitrogen 40 Minutes later, place in an ice-water mixed bath and irradiate with an ultraviolet lamp for 2.5 hours until the reaction is complete, then wash and dry to obtain epoxy-based porous polymer microspheres.

[0073] S2: At room temperature, mix the epoxy-based porous polymer microspheres with 3-butenyl-1-amine according to a mass ratio of 1:0.5, and react for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com