PVC/PCA composite coating fabric of sanitary tent and processing technology of PVC/PCA composite coating fabric

A composite coating and coating composition technology, applied in the field of fabrics, can solve problems such as poor anti-aging performance, low-temperature embrittlement and cracking, and flammability, and achieve high peel strength, strong durability, and improved durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

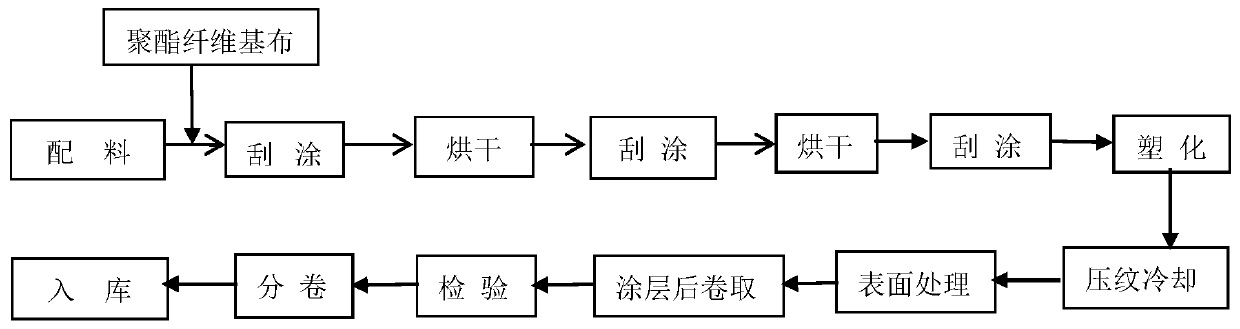

Method used

Image

Examples

Embodiment 1

[0042] A sanitary tent PVC / PCA composite coating fabric fabric is made by coating the surface of a polyester fiber fabric with the sanitary tent PVC / PCA composite coating composition. The polyester fiber fabric surface is coated with the sanitary tent PVC / PCA composite coating composition, thereby forming a PVC / PCA functional coating on the polyester fiber fabric surface. The PVC / PCA functional coating is also provided with an anti-pollution layer coated with PVDF / acrylic resin slurry.

[0043] Wherein, sanitary tent PVC / PCA composite coating composition is mixed by the following raw materials of weight part:

[0044] 50 parts of PVC paste resin,

[0045] 50 parts of PCA copolymer resin,

[0046] 50 parts of 1,2-cyclohexane-diisononyl dicarboxylate (environmentally friendly plasticizer),

[0047] 5718T (environmental protection composite stabilizer) 3 parts,

[0048] Antimony trioxide (flame retardant) 15 parts,

[0049] Antibacterial and antifungal agent JYK ABF-2483 par...

Embodiment 2

[0059] A sanitary tent PVC / PCA composite coating fabric fabric is made by coating the surface of a polyester fiber fabric with the sanitary tent PVC / PCA composite coating composition. The polyester fiber fabric surface is coated with the sanitary tent PVC / PCA composite coating composition, thereby forming a PVC / PCA functional coating on the polyester fiber fabric surface. The PVC / PCA functional coating is also provided with an anti-pollution layer coated with polyvinylidene fluoride / acrylic (PVDF / acrylic) resin slurry.

[0060] Wherein, sanitary tent PVC / PCA composite coating composition is mixed by the following raw materials of weight part:

[0061] 70 parts of PVC paste resin,

[0062] 30 parts of PCA copolymer resin,

[0063] Acetyl tributyl citrate (ATBC) (environmentally friendly plasticizer) 40 parts,

[0064] Environmentally friendly composite stabilizer: 1.5 parts of calcium stearate, 1.5 parts of zinc stearate,

[0065] DPK (flame retardant) 10 parts, aluminum hy...

Embodiment 3

[0075] A sanitary tent PVC / PCA composite coating fabric fabric is made by coating the surface of a polyester fiber fabric with the sanitary tent PVC / PCA composite coating composition. The polyester fiber fabric surface is coated with the sanitary tent PVC / PCA composite coating composition, thereby forming a PVC / PCA functional coating on the polyester fiber fabric surface. The PVC / PCA functional coating is also provided with an anti-pollution layer coated with acrylic resin slurry.

[0076] Wherein, sanitary tent PVC / PCA composite coating composition is mixed by the following raw materials of weight part:

[0077] 90 parts of PVC paste resin,

[0078] 10 parts of PCA copolymer resin,

[0079] 1,2-cyclohexane-diisononyl dicarboxylate (UN899) (environmentally friendly plasticizer) 50 parts,

[0080] 5718T (environmentally friendly composite stabilizer): 4 parts,

[0081] 30 parts of composite flame retardant (4 parts of zinc borate, 10 parts of DPK, 5 parts of antimony trioxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com