Co-extrusion adhesive film, solar cell module and double-layer glass

An adhesive film layer and adhesive film technology, applied in electrical components, glass/slag layered products, circuits, etc., can solve the problems of long cross-linking time affecting the preparation cycle, easy delamination of co-extruded adhesive films, etc., to reduce delamination Layer risk, facilitate industrialization, improve the effect of viscosity performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

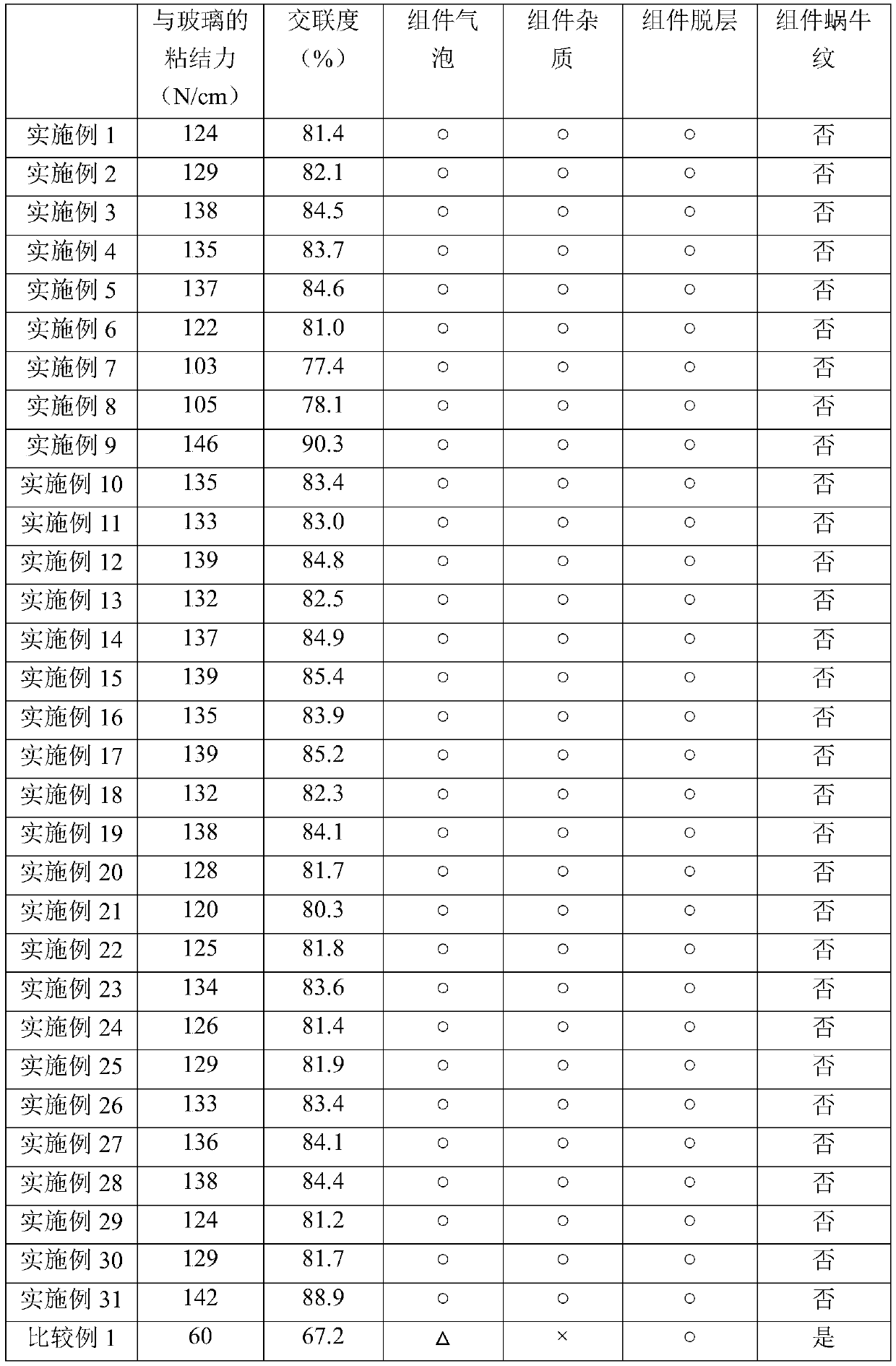

Examples

Embodiment 1

[0048] The raw material of the first adhesive film layer: by weight, get 30 parts of base resin ethylene-vinyl acetate copolymers (VA content is 28wt%, U.S. Dupont), 70 parts of vinyltrimethoxysilane grafted ethylene-acetic acid Vinyl ester copolymer (VA content is 28wt%, graft rate 2wt%, U.S. DuPont), add 1.5 parts of catalyst N, N-dimethylbenzylamine, 0.8 parts of crosslinking agent 2,5-dimethyl-2, 5-bis(tert-butylperoxy)hexane, 0.8 parts of trimethylolpropane trimethacrylate as a co-crosslinking agent.

[0049] The raw material of the second adhesive film layer: in parts by weight, get 10 parts of base resin ethylene-hexene copolymers (U.S. Dow), 80 parts of vinyltrimethoxysilane grafted ethylene-hexene copolymers (grafting rate 2wt%, American Dow), 10 parts of water producing agent calcium disulfate monohydrate masterbatch, 10 parts of water producing agent 1,3-propanediol. Among them, the calcium sulfate monohydrate master batch is obtained by granulating calcium sulfate...

Embodiment 2

[0052] The raw material of the first adhesive film layer: in parts by weight, get 100 parts of ethylene-octene copolymers grafted by isocyanate groups (grafting rate 3wt%, U.S. Dow), 1 part of catalyst ethylene glycol, 0.01 part of catalyst Stannous octoate, 2 parts crosslinker 1,1-bis(tert-amylperoxy)cyclohexane, 0.02 part crosslinker trimethylolpropane triacrylate, 1.0 part crosslinker ethoxylated triglyceride 0.8 parts of acrylate tackifier vinyl triperoxy tert-butyl silane, 0.8 parts of light stabilizer bis-2,2,6,6-tetramethylpiperidinol sebacic acid, 20 parts of titanium dioxide.

[0053] The raw material of the second adhesive film layer: in parts by weight, get 100 parts of ethylene-octene copolymers (grafting rate 3wt%, U.S. Dow) of isocyanate group grafting, 5 parts of water producing agents (calcium oxide and lauryl acid masterbatch), 20 parts of water generating agent 1,4-butanediol. Among them, the masterbatch of calcium oxide and lauric acid is obtained by granul...

Embodiment 3

[0056] The raw material of the first adhesive film layer: in parts by weight, 50 parts of base resin ethylene-propylene copolymers (U.S. Dow), 50 parts of ethylene-propylene copolymers (U.S. Dow) containing 1.0% acid anhydride, 2.5 parts of catalyst Sanya Ethylenediamine, 0.5 parts of cross-linking agent tert-butyl peroxyisopropyl carbonate, 0.9 parts of auxiliary cross-linking agent triallyl isocyanurate, 0.5 parts of tackifier vinyl triethoxysilane, 0.02 Parts light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate.

[0057] The raw material of the second film layer: in parts by weight, get 20 parts of ethylene-propylene copolymers (U.S. Dow) containing 1.0% acid anhydride, 80 parts of ethylene-pentene copolymers (U.S. Dow) containing 1.2% mercapto , 0.5 parts of catalyst N,N-dimethylcyclohexylamine, 2 parts of first crosslinking agent 1,1-bis(tert-amylperoxy)cyclohexane, 0.02 parts of co-crosslinking agent trimethylolpropane Acrylates, 0.8 parts of the first cross...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com