Multilayer type power inductor

一种功率电感、间隙层的技术,应用在电感器、固定电感器、电感/变压器/磁铁制造等方向,能够解决电感变化较大、多层型功率电感器厚度增加、功率电感器产生应力等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0105] According to the interstitial layer composition of the present invention by adding TiO based on 100mol% 2 The raw material is 0.001mol% CuO, 0.001mol% ZnO, 0.001mol% Fe 2 o 3 , and 0.001mol% Bi 2 o 3 to prepare.

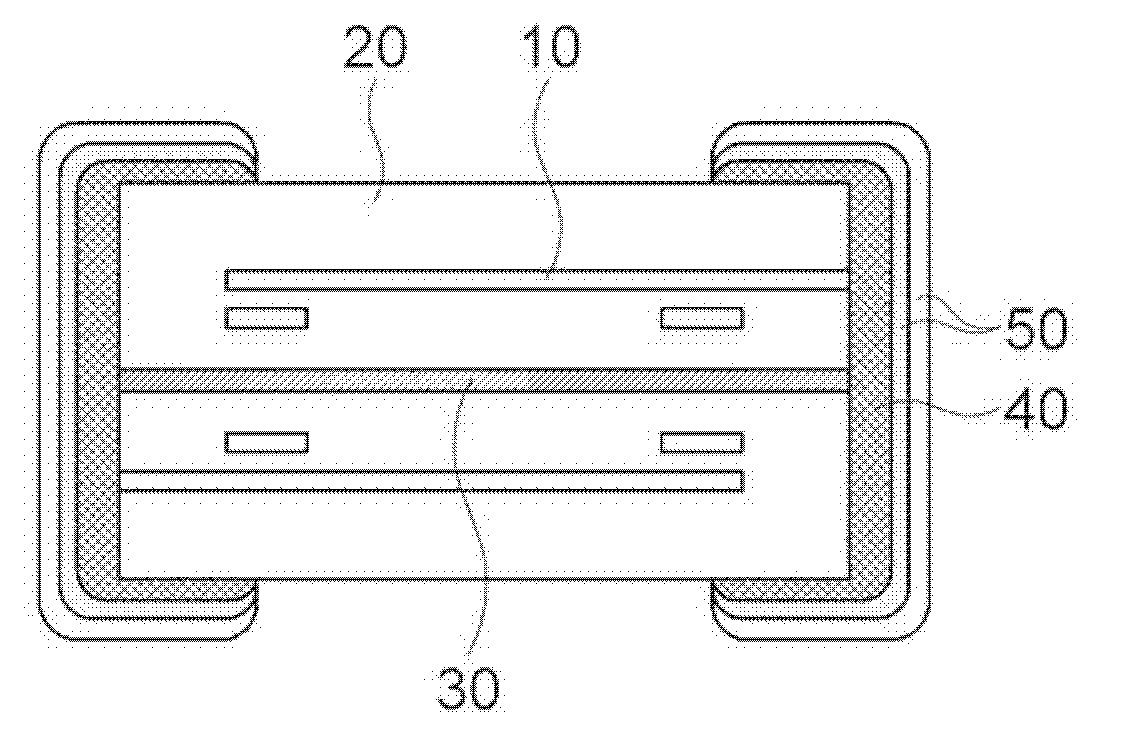

[0106] A gap layer comprising a gap layer composition prepared and having such as Figure 8 The structure shown is a multilayer type power inductor.

[0107] Ag is used as the material of the internal electrodes, and the bulk layer is formed by adding thereto at least one additive selected from Bi within 0.2 mol% based on 100 mol% of NiZnCu ferrite 2 o 3 , CoO and TiO 2 composed of groups.

[0108] The multilayer type power inductor according to the present invention has a structure in which three gap layers (15 μm) are formed between bulk layers.

experiment example 1

[0112] Experimental Example 1: Structure Confirmation

[0113] The structures of the gap layer and the bulk layer of the multilayer type power inductors manufactured according to Example 1 and Comparative Example 1 of the present invention were observed using a scanning electron microscope (SEM). The observed results are shown in Figure 9A to Figure 9C and Figure 10 middle.

[0114] In accordance with Comparative Example 1 in which the existing ZnCu ferrite was used as the material of the gap layer Figure 9A In the case of , the gap layer and the bulk layer are formed separately. However, it was confirmed from actual SEM photographs that the gap layer 30 and the bulk layer 20 were almost indistinguishable from each other.

[0115] However, from Figure 9B It can be confirmed that the interstitial layer 30 formed according to the present invention has a non-porous structure 31 at a portion in contact with the bulk layer 20, and has a porous structure 32 at a portion n...

experiment example 2

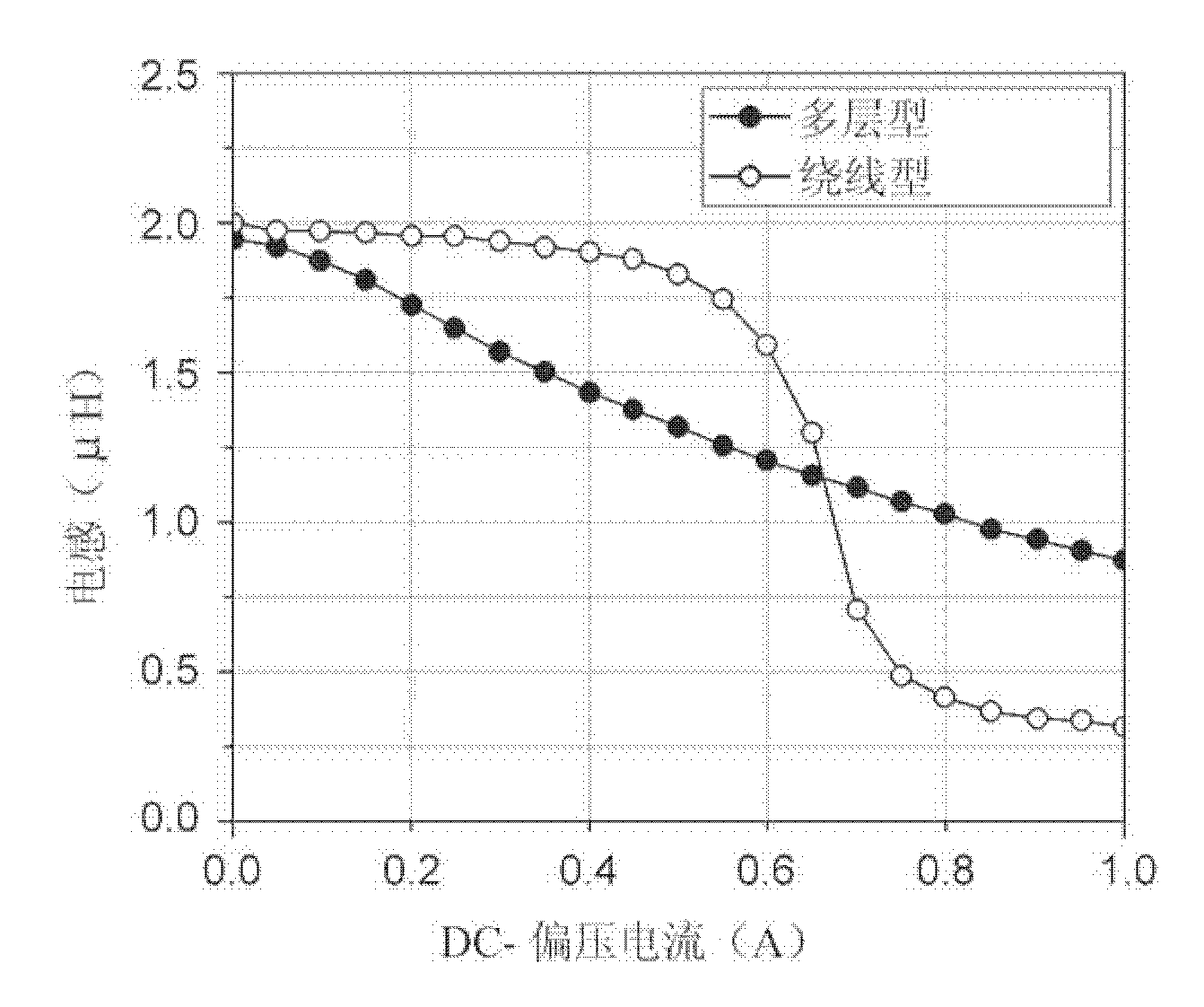

[0117] Experimental Example 2: Confirmation of Bias-TCL Characteristics

[0118] The bias-TCL characteristics of the multilayer power inductors manufactured according to Example 1 and Comparative Example 1 of the present invention were confirmed. Confirmed results are shown in Figure 11 and Figure 12 middle.

[0119] The upper limit of the inductance value of the bias-TCL of each of the multilayer type power inductors manufactured according to Example 1 and Comparative Example 1 of the present invention was about 6 μH, and each of the bias-TCL characteristics was at 0.5 A The following is confirmed based on the inductance value of 2.25μH.

[0120] In the case of the multilayer type power inductor manufactured according to Comparative Example 1, it was confirmed that the bias-TCL characteristics significantly differed with temperature, as Figure 11 shown. That is, it was confirmed that the initial inductance value has a significant difference with temperature. In add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com