Environment-friendly clean production method of high-purity glycolic acid

A high-purity glycolic acid, clean production technology, applied in general water supply conservation, separation/purification of carboxylic acid compounds, chemical industry, etc. Concentration requirements, improving single-pass yield, and reducing the effect of concentration difference osmosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

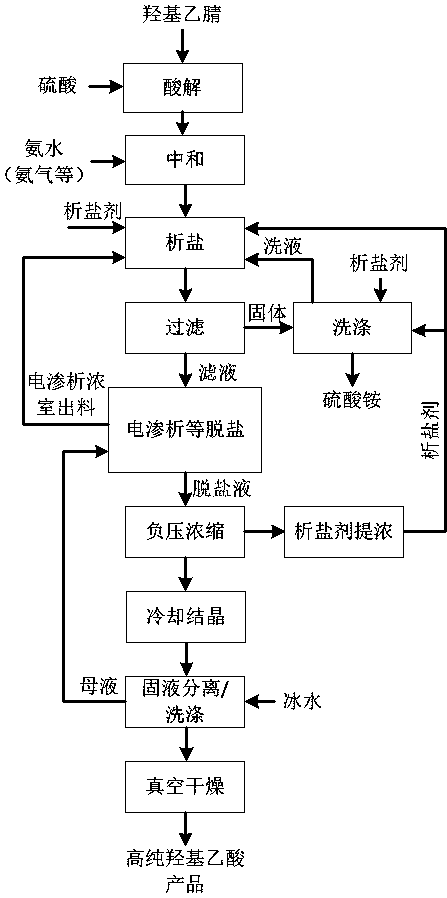

Image

Examples

Embodiment 1

[0045] Example 1: 191kg of sulfuric acid with a concentration of 90wt% was added to the reaction kettle, and 312.5kg of hydroxyacetonitrile with a concentration of 40% was slowly added dropwise to carry out acidolysis reaction. And the acid solution of ammonium sulfate acid salt. After the acidolysis solution was cooled to normal temperature, 18 wt% ammonia water was added with stirring until the pH value of the reaction solution was 2.0 to obtain a neutralization solution.

[0046] Slowly add the ethanol of concentration 96wt% in the neutralization liquid to carry out salt analysis, the ethanol addition is 1.1 times of the water yield in the neutralization liquid, filter and separate the ammonium sulfate solid to obtain the filtrate, add the filtrate amount after the water dilution of 0.2 times of glycolic acid amount is 605.1kg (containing 27.34wt% of glycolic acid, 2.55wt% of ammonium sulfate, 36.64% of water, and 32.92% of ethanol); the ammonium sulfate solid was washed wi...

Embodiment 2

[0048] Embodiment 2: Add 217.3kg of sulfuric acid of 80wt% concentration in the reaction kettle, slowly dropwise add 310.7kg of hydroxyacetonitrile with a concentration of 35% to carry out acidolysis reaction, after the dropwise addition, heat preservation reaction at 95~105°C for 6.5h to obtain Acid hydrolyzate of glycolic acid and ammonium sulfate acid salt. After the acidolysis solution was cooled to normal temperature, 23 wt% ammonia water was added with stirring until the pH value of the reaction solution was 3.8 to obtain a neutralization solution.

[0049] Slowly add tert-butanol with a concentration of 85wt% to the neutralization solution to carry out salt precipitation. The mass of tert-butanol added is 0.7 times the amount of water in the neutralization solution, and the solid ammonium sulfate is filtered to obtain the filtrate, which is diluted with water of 0.15 times the amount of glycolic acid The amount of filtrate is 584.7kg (containing 24.66wt% of glycolic aci...

Embodiment 3

[0051] Embodiment 3: same as embodiment 2, hydroxyacetonitrile and sulfuric acid are neutralized after acidolysis to obtain a neutralization solution, and slowly add n-propanol with a concentration of 70wt% in the neutralization solution to carry out salt precipitation, and the quality of n-propanol added is the neutralization solution 0.7 times the amount of water in the middle, filter and separate the ammonium sulfate solid to obtain the filtrate, add 0.35 times the amount of glycolic acid to dilute the amount of the filtrate after water dilution is 561.0kg (containing glycolic acid 21.81wt%, ammonium sulfate 3.18wt%, water 51.14%, n-propyl Alcohol 23.39%); wash the ammonium sulfate solid with an appropriate amount of n-propanol, and apply the lotion to remove salt; dry the wet ammonium sulfate to obtain by-product ammonium sulfate, condense and recover the n-propanol in the exhaust gas to remove salt. Add modified zeolite molecular sieve to the filtrate for decolorization an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com