A mobile powder injection process

A process method and mobile technology, applied in the direction of conveying bulk materials, transportation and packaging, conveyors, etc., can solve problems such as unfavorable production, damage to stirring mechanism, dust adhesion, etc., to achieve uniform airflow purging pressure distribution, avoid powder The effect of material sticking to the wall and eliminating the system material residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

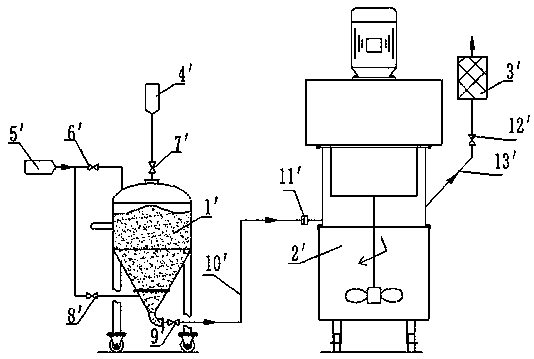

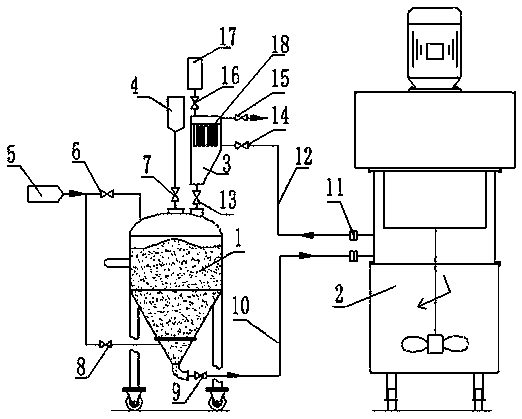

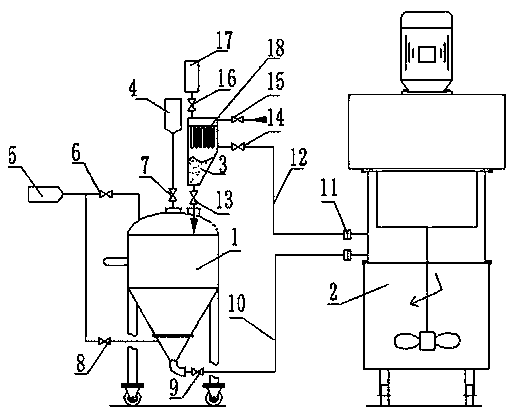

[0024] Such as figure 2 and image 3 As shown, the process method of the system includes the following steps:

[0025] Step (1) The third valve 7 of the sending tank 1 is opened, and the powder enters the sending tank 1 from the feeding port 4 to the set value;

[0026] Step (2) sending tank 1 moves to receiving tank 2, is connected to receiving tank 2 by connector 11 with discharge connecting pipe 10;

[0027] Step (3) The third valve 7 and the fourth valve 9 are closed, the first valve 6 and the second valve 8 are opened, and the compressed air enters the sending tank 1 from the air inlet port 5 to be fluidized and pressurized. After reaching the set pressure, The fourth valve 9 is opened, and the powder material starts to be transported into the receiving tank 2. At this time, the fifth valve 14 and the vacuum breaking valve 15 are opened, and most of the material remains in the receiving tank 2. A small amount of powder material passes through the return pipe 12 along w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com