A metal fiber mesh dust collector

A metal fiber and dust collector technology, applied in chemical instruments and methods, separation methods, transportation and packaging, etc., can solve the problems of sticky, high-temperature, flammable and explosive dust, etc., to reduce the volume and weight of equipment, and achieve high dust removal efficiency , Improving the effect of using safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

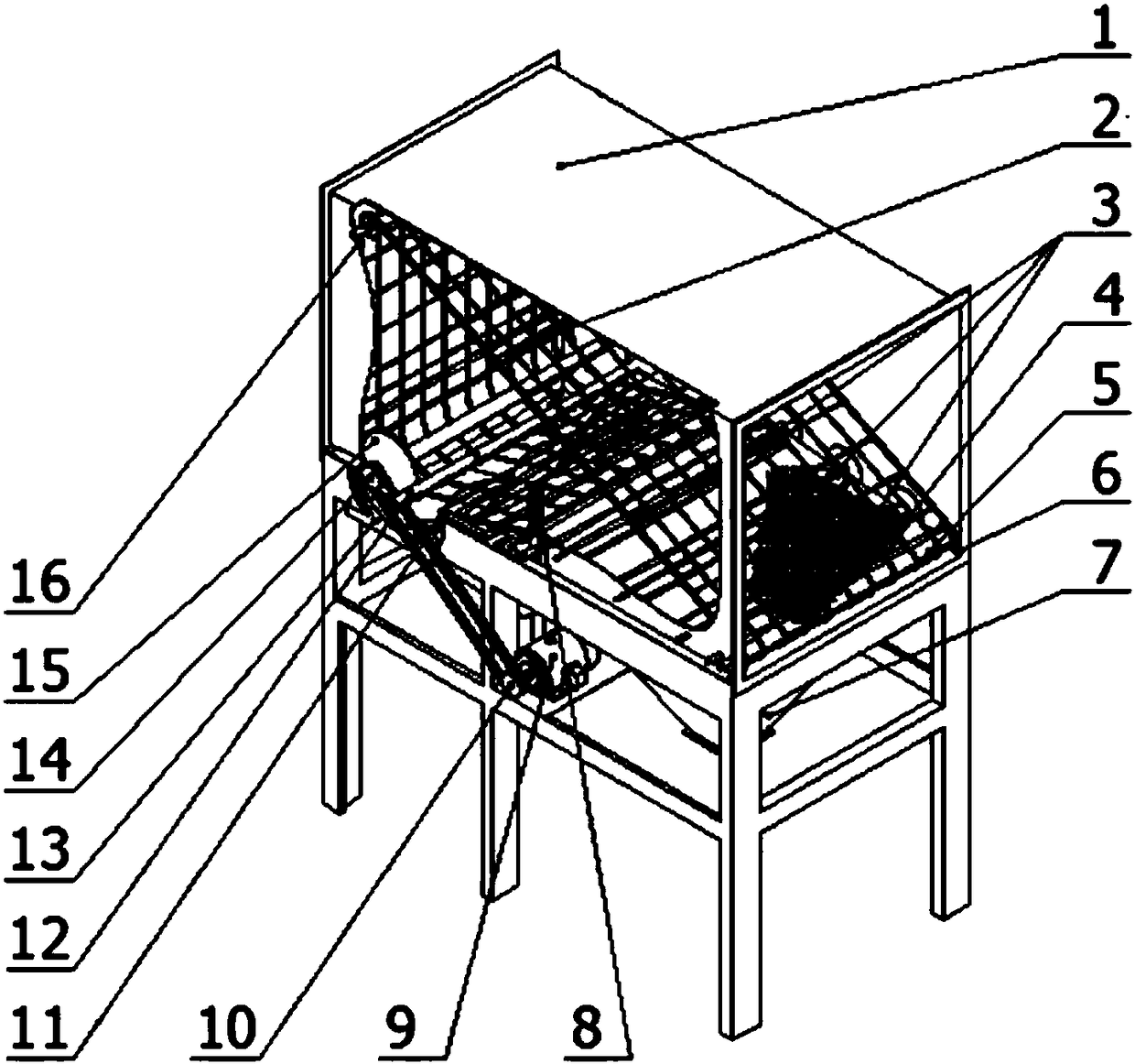

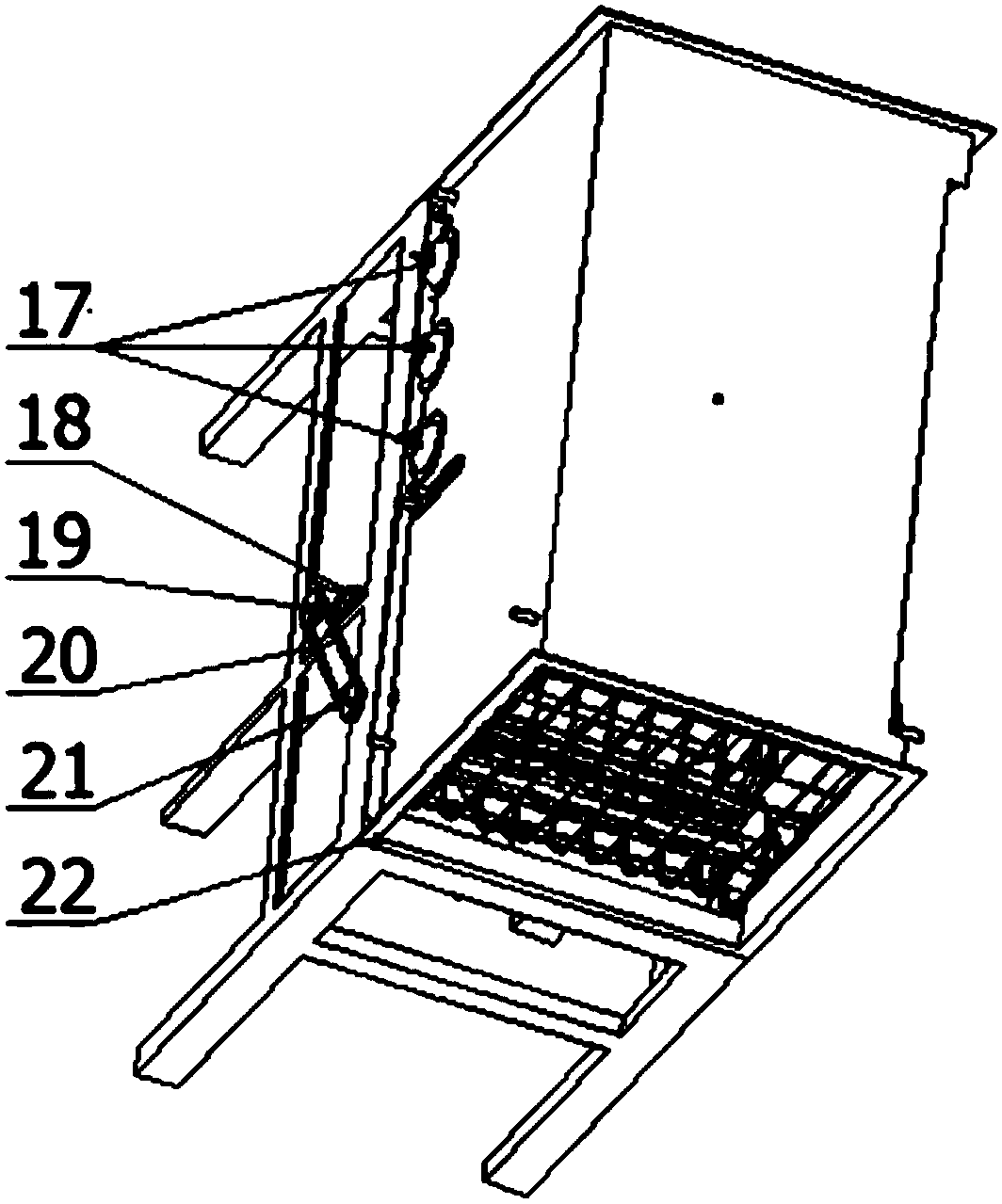

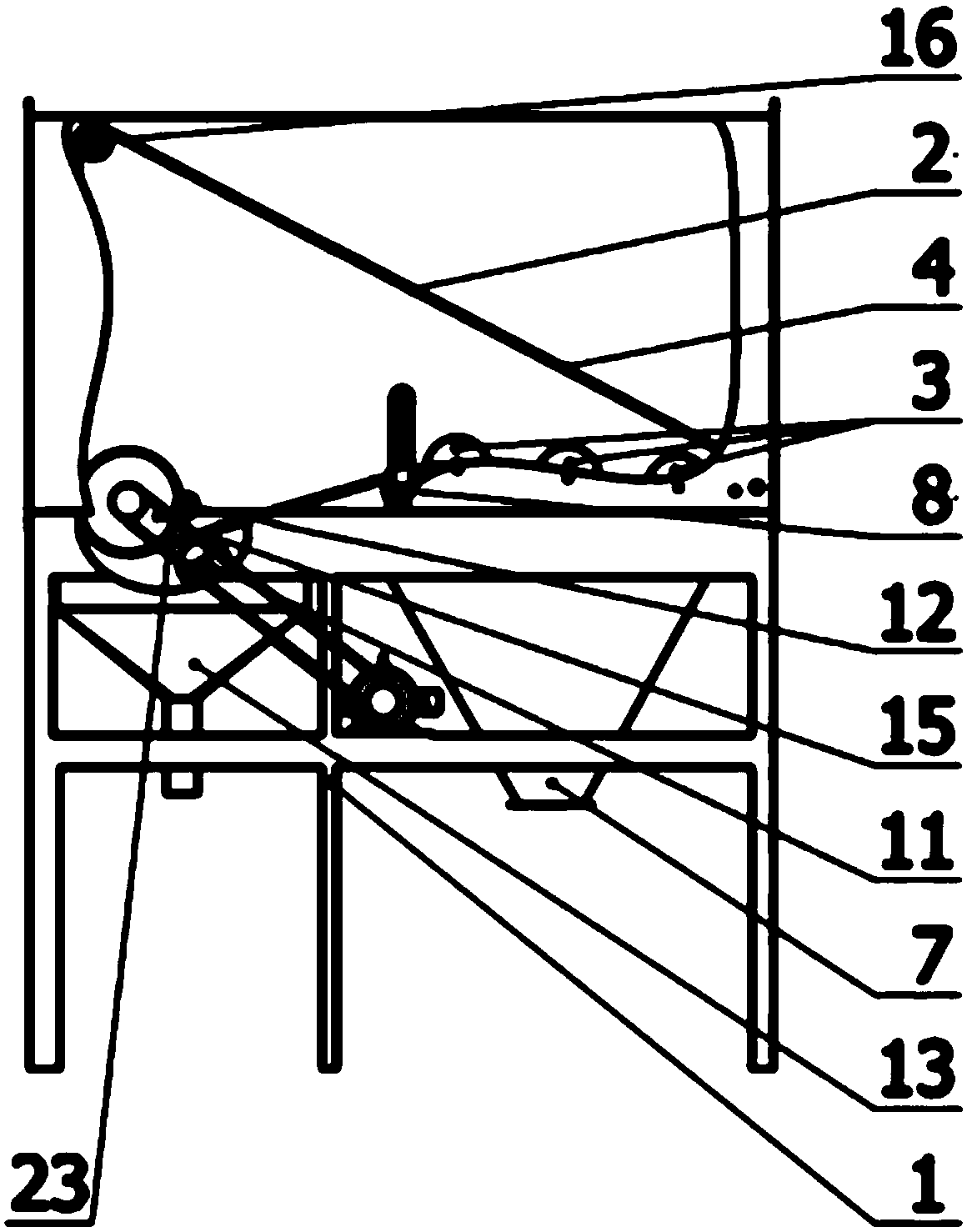

[0034] A metal fiber mesh felt dust collector, its structure is as follows figure 1 , figure 2 and image 3 As shown, the dust collector includes:

[0035] Box 1: including an air inlet 6 and an air outlet 22 oppositely arranged on the side of the box;

[0036] Filter unit: set between the air inlet 6 and the air outlet 22, including the transmission sprocket a5 arranged at the lower end of the air inlet 6, the transmission sprocket b16 arranged at the upper end of the air outlet 22, and the drive chain arranged at the lower end of the air outlet 22 Axle 15, metal mesh belt 2 and the metal fiber mesh felt 4 that is arranged on the outside of metal mesh belt 2, metal mesh belt 2 is connected on the outside of drive sprocket a5, drive sprocket b16 and drive sprocket shaft 15, and is arranged in a right triangle, The circulation direction of the metal mesh belt 2 is drive sprocket a5 → drive sprocket shaft 15 → drive sprocket b16 → drive sprocket a5; the metal fiber mesh felt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com