Internal combustion engine exhaust particulate matter purification device with flexible and adjustable working parameters

A technology of working parameters and purification devices, applied in exhaust devices, exhaust treatment, noise reduction devices, etc., can solve problems affecting performance, cleaning and regeneration of purification devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

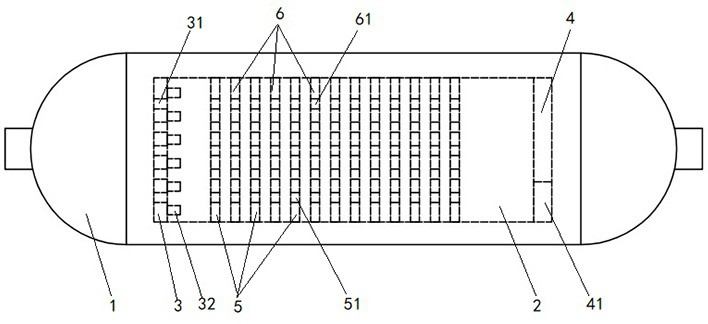

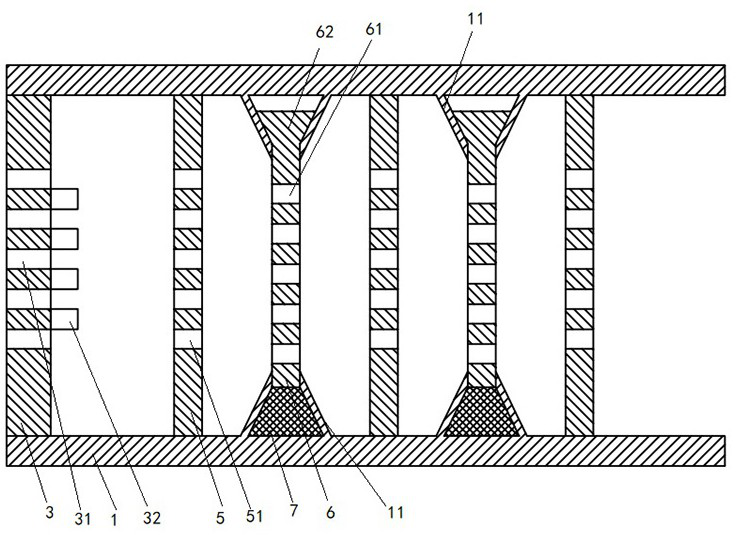

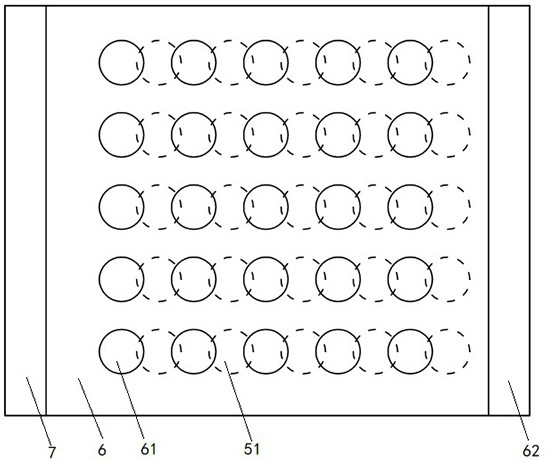

[0019] Please combine figure 1 As shown, the structure of the internal combustion engine exhaust particulate matter purification device with flexible and adjustable working parameters involved in this embodiment includes a cylindrical body 1. vehicle installation. A rectangular parallelepiped exhaust flow channel 2 is formed inside the cylindrical body 1 , and a sealing plate 3 is formed at the front end of the exhaust flow channel 2 , through which exhaust gas from the internal combustion engine enters the exhaust flow channel 2 . The rearmost end of the exhaust circulation channel 2 is the tail end plate 4, and the tail end plate 4 is provided with an exhaust outlet 41, and the exhaust gas of the internal combustion engine is discharged from the cylindrical body 1 through the exhaust outlet 41 after passing through the exhaust ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com