Filter plate assembly with split feed channel and backwashing and back blowing air drying functions

A feed filter plate and feed channel technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of easy blockage of feed holes, decrease of filter cake degree, loss of filtrate, etc., and achieve feed filtration High efficiency, clean and smooth cake unloading, high performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to understand the characteristics and technical content of the present invention in more detail, the implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The attached drawings are only for reference and description, and are not intended to limit the present invention.

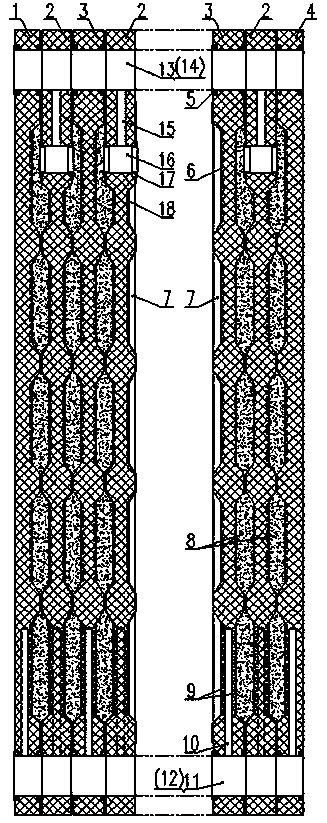

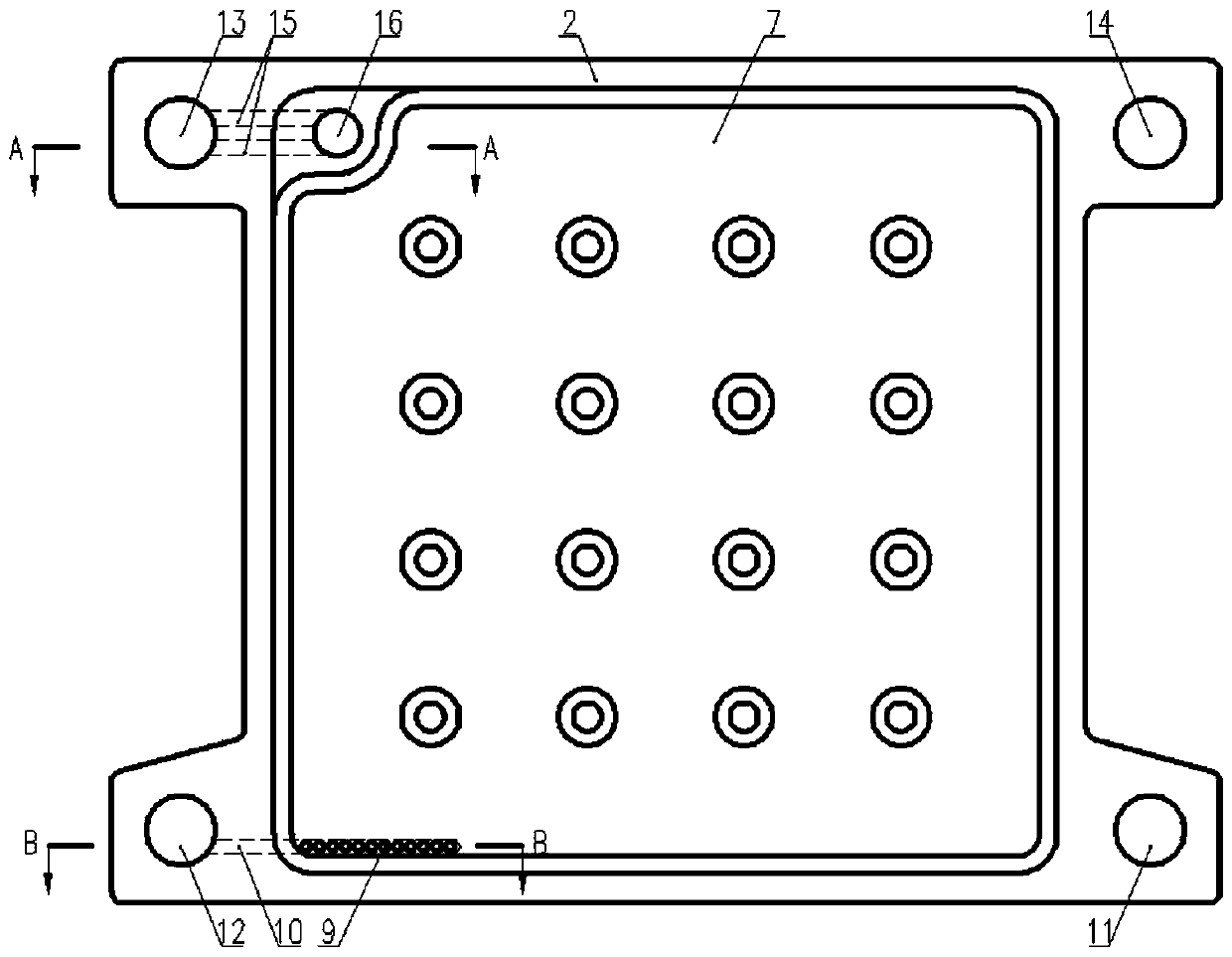

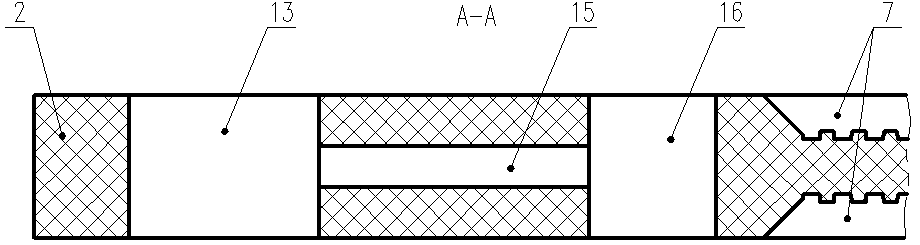

[0037] like Figure 1-10 As shown, as one of the preferred structural forms, the embodiment of the present invention is a filter plate assembly with a split feed channel and backwashing and blow-drying. Each filter plate is designed as an ear plate type, including the tail filter plate 1, the middle filter plate , the head filter plate 4, the filter cavity 7 is formed between the filter plates, and the middle filter plate includes the feed filter plate 2 and the filter filter plate 3 arranged alternately starting and ending with the feed filter plate 2, and There is at least one feed filter plate 2; channels are provided above a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com