Chemical mechanical polishing solution and application thereof

A chemical mechanical and polishing liquid technology, which is applied to the polishing composition containing abrasives, etc., can solve the problems of unstable polishing liquid, difficult removal, decomposition failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

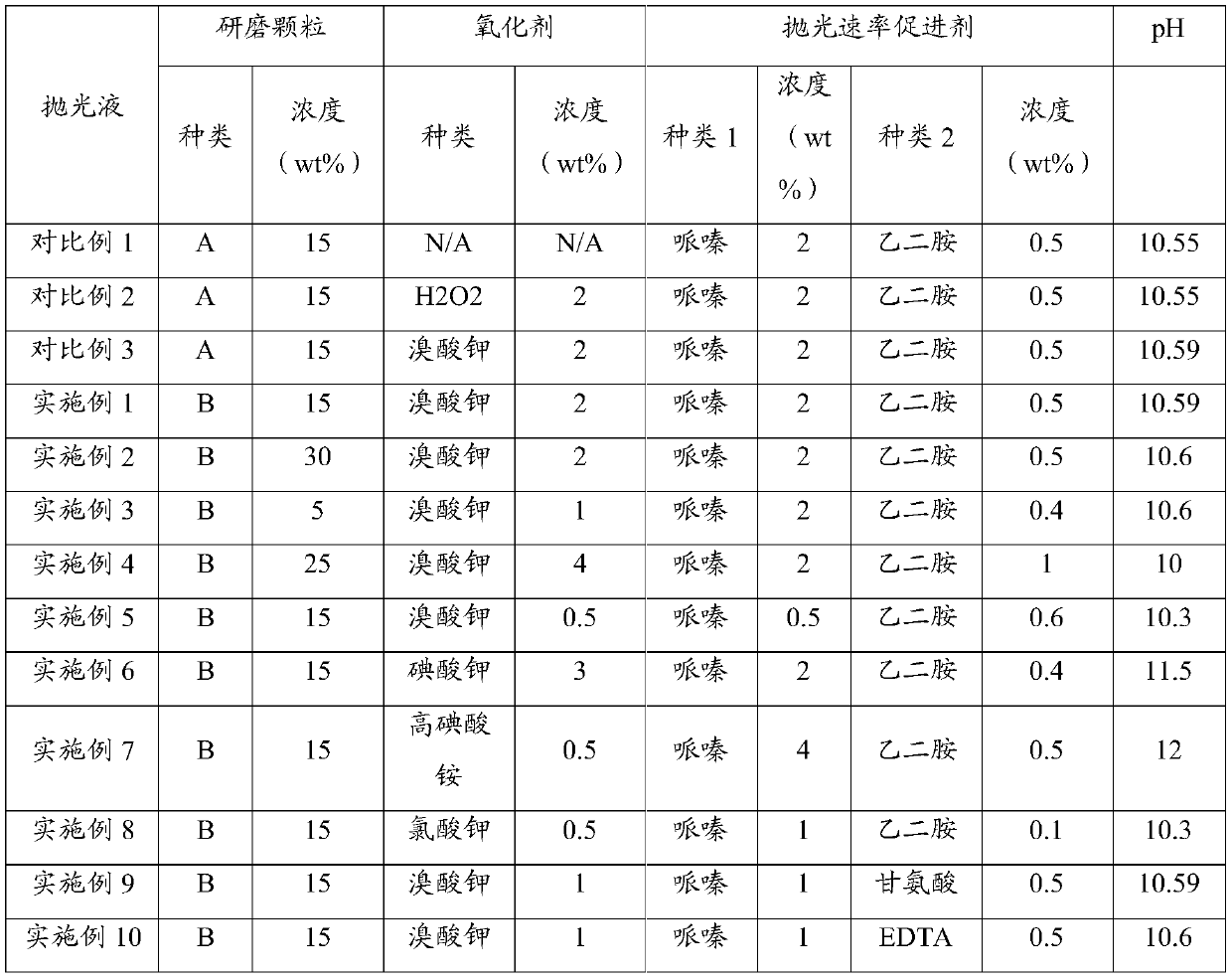

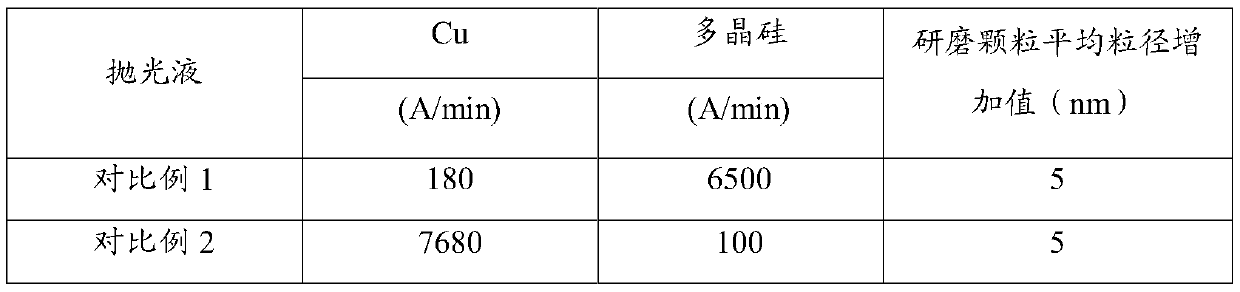

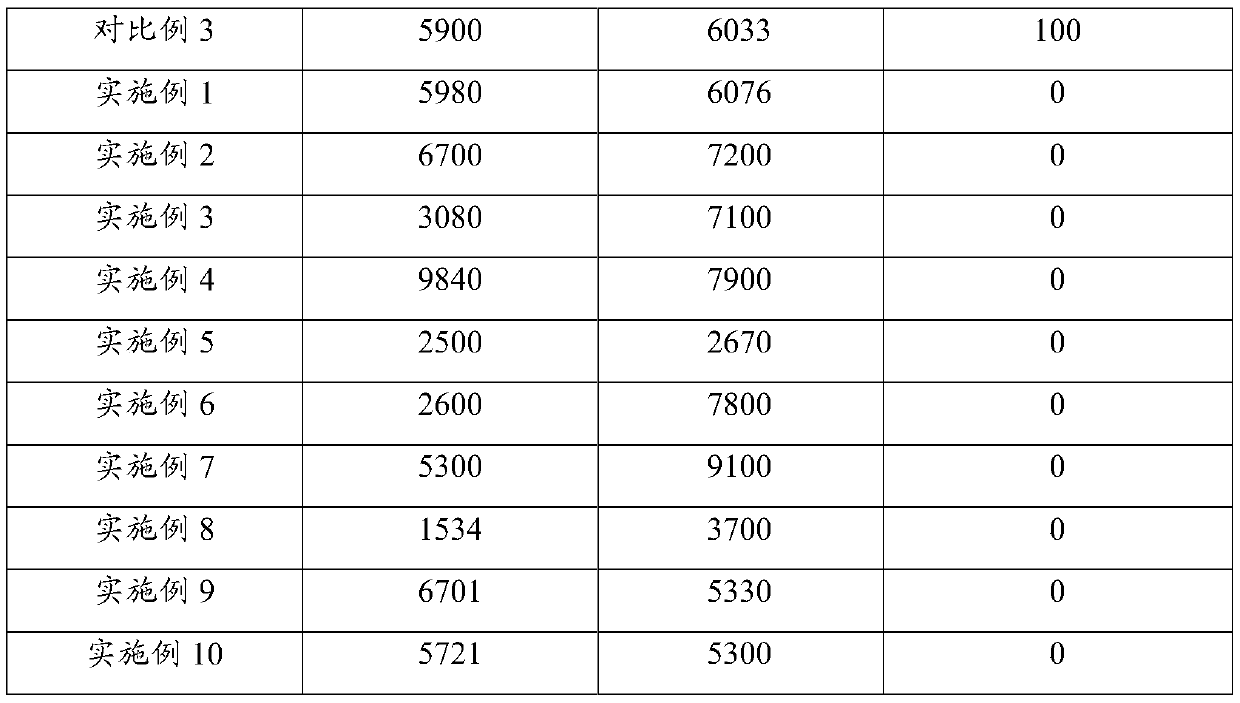

[0038] Table 1 shows the composition and content of the polishing solutions of Examples 1-10 of the present invention and Comparative Examples 1-3. Mix evenly according to the ingredients and their proportions in Table 1, and make up the mass percentage to 100% with water. Adjust the required pH value with nitric acid, KOH or tetramethylammonium hydroxide to obtain the polishing solutions of the examples and comparative examples in Table 1.

[0039] In Table 1, type A of abrasive grains is conventional silica abrasive grains, and type B of abrasive grains is silica abrasive grains grafted on the surface with organic substances with terminal sulfonic acid groups.

[0040] The polishing liquid formula of table 1 embodiment 1-10 of the present invention and comparative example 1-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com