Gold ore dressing and smelting combined recovery process

A combination of beneficiation and smelting technology, applied in the direction of process efficiency improvement, flotation, solid separation, etc., can solve the problems of single, single leaching, smelting and purification, difficult to achieve recovery rate and concentrate grade of minerals, etc., and achieve low process cost. , The effect of high product quality and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

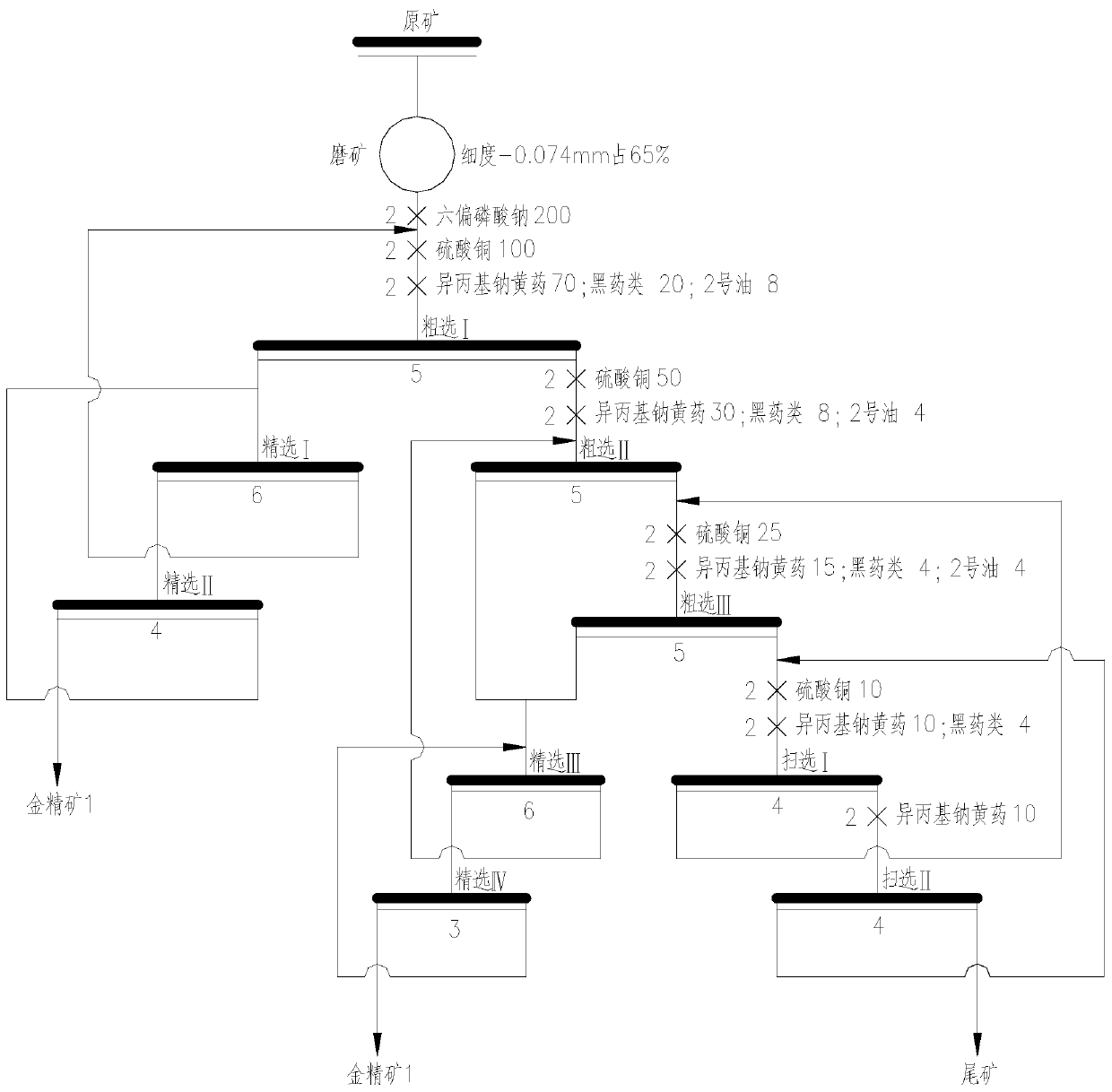

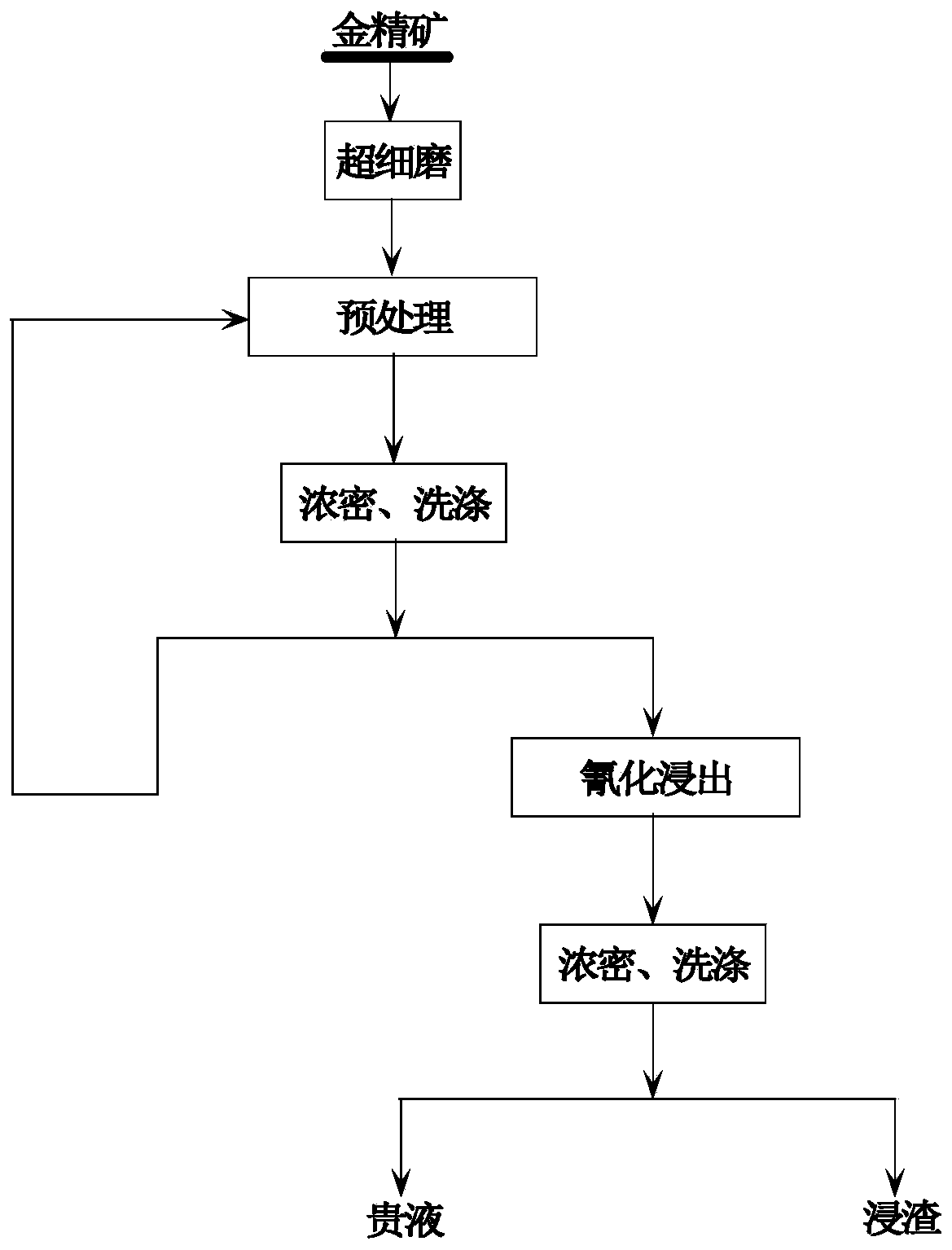

[0030] see figure 1 , figure 2 , a flotation process flow chart of a gold ore dressing and metallurgy combined recovery process, a gold ore beneficiation and metallurgy combined recovery process flow chart of a gold concentrate chemical pretreatment cyanide leaching process, a foreign gold mine, the grade of gold in the raw ore The grade of arsenic in the raw ore is 0.6%; the gangue minerals are mainly quartz, iron dolomite, chlorite, muscovite, albite; the embedded particle size of gold in the raw gold ore is 4-11 microns, and the Wrapped in pyrite, arsenopyrite, sulfide ore, and gangue minerals; the following process is used to recover gold, and the raw ore extracted from mining is crushed, and the crushing particle size is controlled at 10-15 mm; the crushed minerals are ground , the grinding fineness is controlled between 65%-90%; the grinding adopts two closed-circuit grinding processes; the concentration of the pulp after grinding is controlled between 33%-36%, adding ...

Embodiment 2

[0032] A gold mine in Yunnan, China, the grade of gold in the raw ore is 6%; the grade of arsenic in the raw ore is 0.7%; the gangue minerals are mainly quartz, anodolomite, chlorite, muscovite, albite; The embedded particle size is 4-11 microns, and the gold is wrapped in pyrite, arsenopyrite, sulfide ore, and gangue minerals; the following process is used to recover gold, and the raw ore extracted from mining is crushed, and the crushing particle size is controlled at 10- 15 mm; grind the crushed minerals, and the grinding fineness is controlled between 65% and 90%; the grinding adopts a two-stage closed-circuit grinding process; the concentration of the pulp after grinding is controlled at 33% -36% In between, add flotation agents, sodium hexametaphosphate 200-400g / t; copper sulfate 100-200g / t; isopropyl sodium xanthate 70-150g / t; black drug collector 20-50g / t; The flotation adopts the flotation closed-circuit process of three times of roughing, two times of sweeping and fo...

Embodiment 3

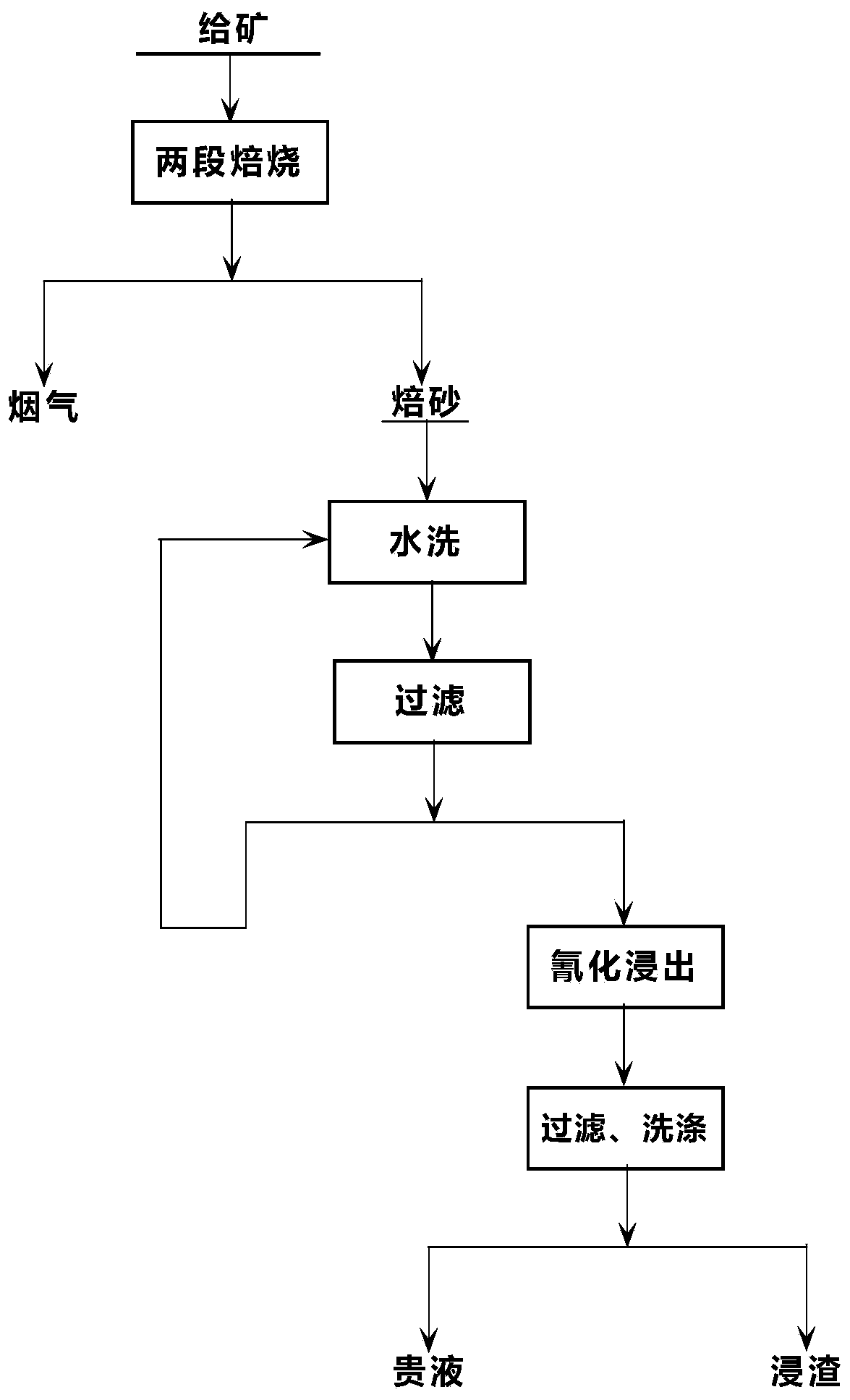

[0034] see figure 1 , image 3 , a flow chart of the flotation process for a combined recovery process of gold ore dressing and smelting, a process flow chart of the roasting and cyanidation leaching of gold concentrate for a combined recovery process of gold ore dressing and metallurgy, a domestic gold mine in Yunnan, the grade of gold in the raw ore is 6%; the grade of arsenic in the raw ore is 0.7%; the gangue minerals are mainly quartz, iron dolomite, chlorite, muscovite, and albite; In pyrite, arsenopyrite, sulfide, and gangue minerals; use the following process to recover gold, crush the raw ore extracted from mining, and control the crushing particle size at 10-15 mm; grind the crushed minerals, Grinding fineness is controlled between 65%-90%; grinding adopts two-stage closed-circuit grinding process; the concentration of pulp after grinding is controlled between 33%-36%, adding flotation reagents, sodium hexametaphosphate 200-400g / t; copper sulfate 100-200g / t; isopro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com