Titanium alloy and stainless steel dissimilar vacuum electronic beam welding method

A technology of vacuum electron beam and welding method, which is applied in the direction of electron beam welding equipment, welding equipment, welding/welding/cutting articles, etc., can solve the problems such as poor welding quality of C4 titanium alloy and 316L stainless steel dissimilar metals, and achieve favorable Precise control, prevention of deformation, favorable effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Grind and polish the surface to be welded between TC4 titanium alloy and AISI 316L stainless steel to make the surface roughness Ra≤1.0μm; then pickle the polished sample, and use hydrofluoric acid for the oxide film on the titanium alloy surface and nitric acid mixed solution to remove; for the oxide film on the surface of copper foil, dilute H 2 SO 4 Then, put the treated titanium alloy, stainless steel, copper foil and niobium foil together into acetone for ultrasonic cleaning for 15 minutes, then wipe the surface of the sample to be welded with alcohol, dry it with cold wind, and finally get Treated titanium alloy, stainless steel, copper foil and niobium foil; the above-mentioned cleaning methods are prior art known in the art;

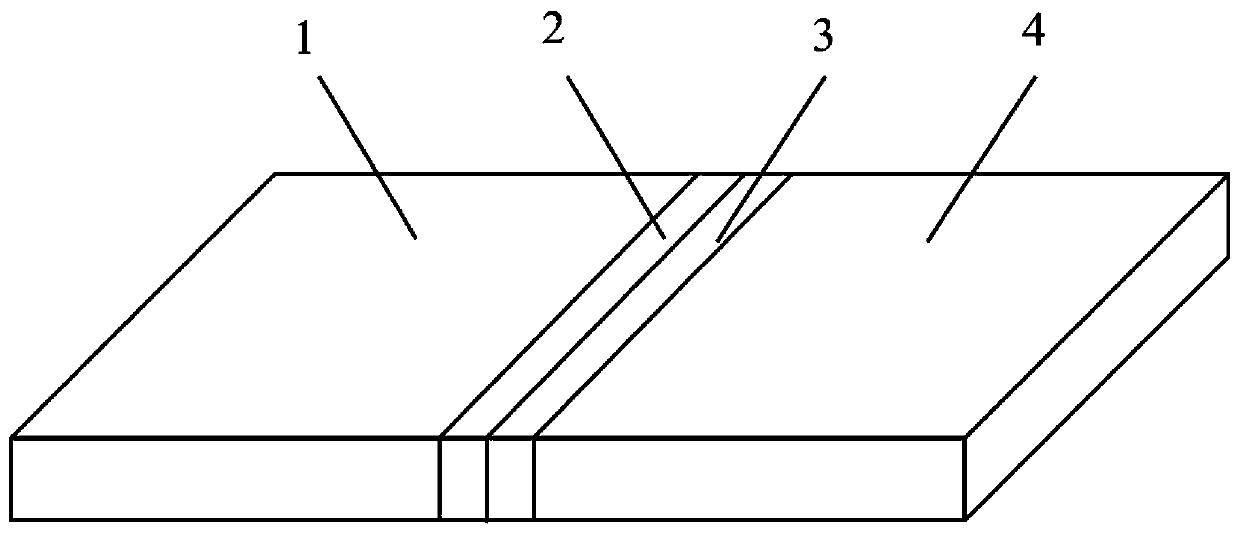

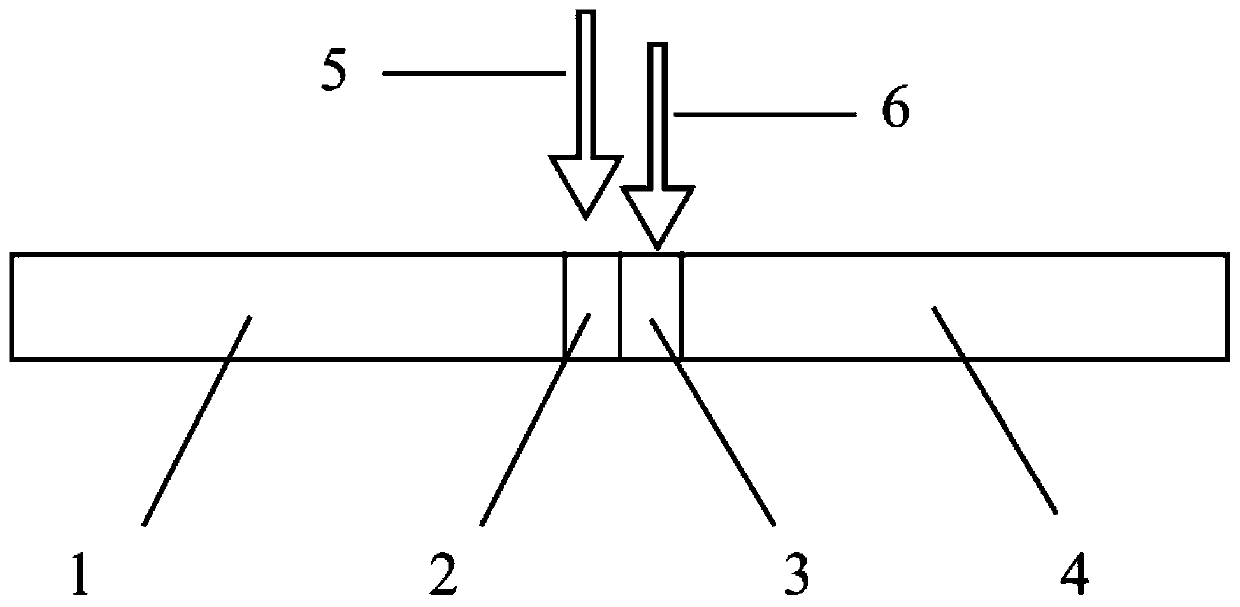

[0046] The processed titanium alloy, stainless steel, 500 μm copper foil and 550 μm niobium foil are docked and placed in a certain order, the sequence is stainless steel-copper foil-niobium foil-titanium alloy. Specific as figure 1 As ...

Embodiment 2

[0050] The same welding process as in Example 1 was used to weld the titanium alloy and stainless steel. The other conditions are the same as in Example 1 except that the electron beam is shifted to the copper foil side by 0.2mm when the first welding is performed on the interface between the copper foil and the stainless steel.

Embodiment 3

[0052] The same welding process as in Example 1 was used to weld the titanium alloy and stainless steel. The other conditions are the same as in Example 1 except that the electron beam is shifted to the copper foil side by 0.3mm when the first welding is performed on the interface between the copper foil and the stainless steel.

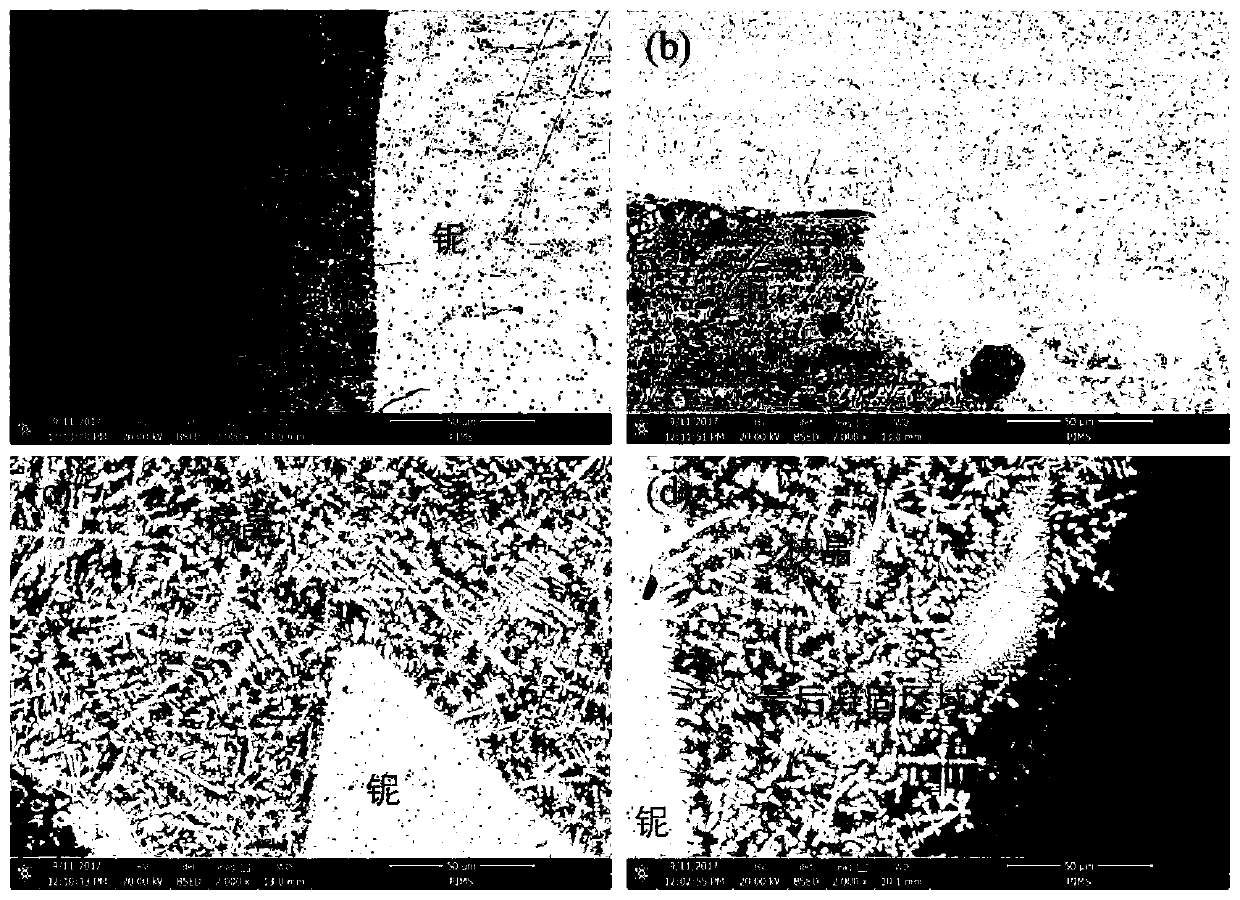

[0053] The microstructure topography figure in the weld zone of this embodiment is shown in image 3 , it can be seen from the figure that the side of the copper foil is mainly composed of copper-iron solid solution, and the side of the niobium foil is mainly composed of titanium-niobium solid solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com