High-toughness insulating epoxy resin cured product as well as preparation method and application thereof

A technology of epoxy resin curing and epoxy resin, applied in the field of high toughness insulating epoxy resin cured products and its preparation, can solve the problems of impact toughness, heat resistance and insulation, etc., and achieve the elimination of microporous defects , reduce the water content, reduce the viscosity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

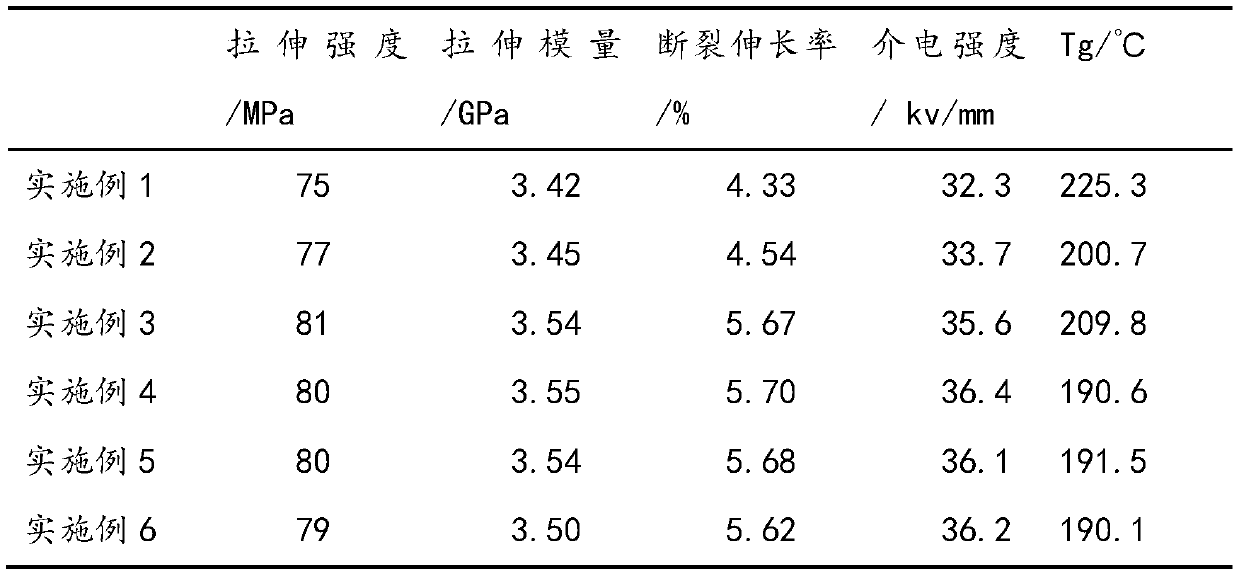

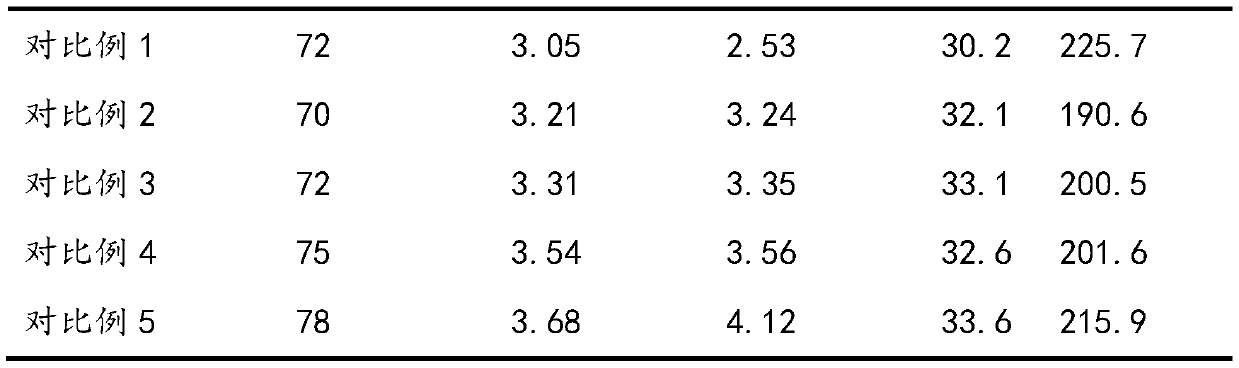

Examples

Embodiment 1

[0038] Prepare raw materials: 50g of matrix resin, composed of Cardolite LITE2020 and tetrafunctional glycidylamine epoxy resin TT410, wherein the mass of Cardolite LITE2020 is 7% of the mass of tetrafunctional glycidylamine epoxy resin TT410; curing Methyltetrahydrophthalic anhydride 42g, accelerator dimethylbenzylamine 0.5g and toughening agent 7.5g, wherein the toughening agent is composed of cardanol glycidyl ether and nano silicon dioxide with a mass ratio of 1:1.

[0039] Preparation of matrix resin: put inactive resin Cardolite LITE2020 and tetrafunctional glycidylamine epoxy resin TT410 in a beaker and mix well;

[0040] Prepare the toughening agent: put cardanol glycidyl ether and nano silicon dioxide into the mixer, pre-mix, and stir evenly;

[0041]Preparation of epoxy resin cured product: mix matrix resin, toughening agent, curing agent and accelerator in a beaker, place in a 70°C constant temperature oil bath, stir for 10 minutes with a stirring paddle, then vacuu...

Embodiment 2

[0043] Prepare raw materials: 40g of matrix resin, composed of Cardolite NX2026 and trifunctional epoxy resin AFG-90, wherein the mass of Cardolite NX2026 is 5% of the mass of trifunctional epoxy resin AFG-90; curing agent A Base hexahydrophthalic anhydride 48g, accelerator triethanolamine 2g and toughening agent 10g, wherein the toughening agent is composed of cardanol glycidyl ether and nano rubber with a mass ratio of 3:7.

[0044] The preparation method is the same as in Example 1.

Embodiment 3

[0046] Prepare raw materials: matrix resin 58g, composed of Cardolite NX2026 and bisphenol A epoxy resin E-51, wherein the mass of Cardolite NX2026 is 10% of the mass of bisphenol A epoxy resin E-51; curing agent A 30 g of kinadic anhydride, 2 g of accelerator 2-ethyl-4-methylimidazole and 10 g of toughening agent, wherein the toughening agent is composed of cardanol glycidyl ether and nano calcium carbonate with a mass ratio of 7:3.

[0047] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com