Preparation method of recycled cementing material

A technology of recycled cementitious materials and mixed powder, which is applied in the direction of cement production, etc., can solve the problems of low resource utilization rate of construction solid waste, low proportion of waste concrete powder, high proportion of old mortar attached, and achieve social benefits and Significant economic benefits, solving the shortage of high-quality clay resources, and no effect on compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

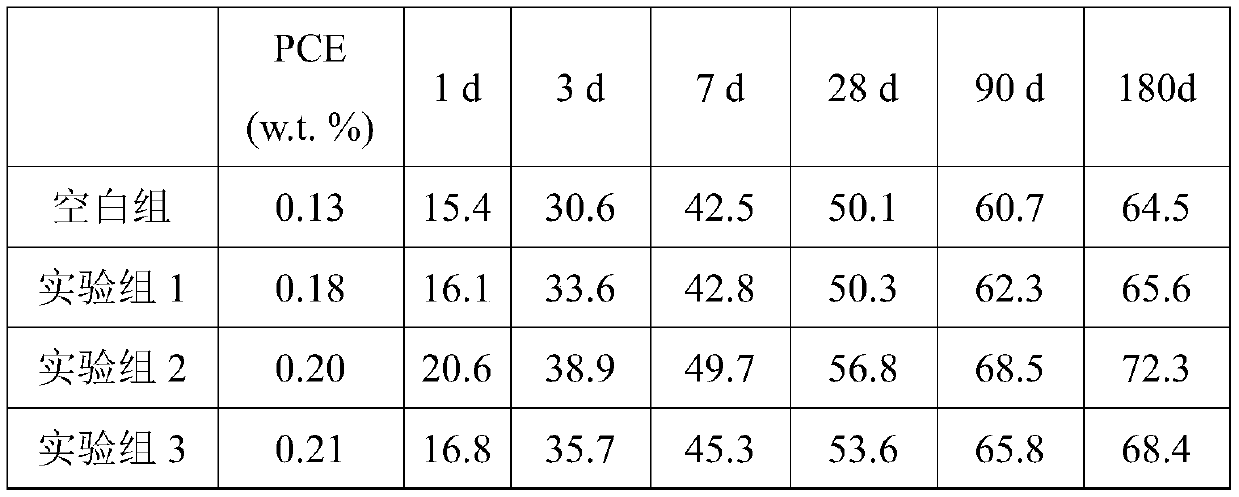

Examples

preparation example Construction

[0015] The applicant found that after the calcareous powder was crushed, cleaned and separated, the calcined and activated powder could make the hydration products calcium silicate hydrate, calcium aluminate hydrate and ferrialuminate hydrate Calcium, ettringite, calcium hydroxide, etc. are transformed into dicalcium silicate and free calcium oxide with hydration activity. When it is directly used for minerals and admixtures, it is easy to increase the water demand of the cement-based material mixture and cause poor stability. At the same time, the clay waste powder contains a certain amount of kaolin, which can be transformed into an aluminosilicate glass body of metakaolin with certain pozzolanic activity after calcination. A large amount of calcium hydroxide can be obtained by reacting the dicalcium silicate and free calcium oxide obtained after the calcareous powder is calcined and activated with water, which can stimulate the active aluminum and silicon components in the ...

Embodiment 1

[0028] Embodiment 1 of the present invention provides a kind of preparation method of regenerated gelling material, comprises the steps:

[0029] (1) Use a laboratory crusher to crush the waste concrete, and use a laboratory small-scale magnetic separator to sort out the iron sundries in the waste concrete; use a 0.125mm sieve to screen the broken waste concrete particles, larger than The 0.125mm waste concrete particles are subjected to secondary crushing until the waste concrete powder smaller than 74um is obtained; the waste concrete powder and clay waste are respectively placed in a ball mill for grinding at a power of 50-100kW for 2 hours until all The particle sizes are all less than 40um. The obtained waste concrete powder and clay powder are placed in a 5L plastic mixing tank according to the mass ratio of 3:1, and processed in the mixer for 12 hours at a speed of 300r / min. For the mixture, mix the mixture and absolute ethanol uniformly according to the solid-to-liquid...

Embodiment 2

[0033] Embodiment 2 of the present invention provides a kind of preparation method of regenerated gelling material, comprises the steps:

[0034](1) Use a laboratory crusher to crush the waste concrete, and use a laboratory small-scale magnetic separator to sort out the iron sundries in the waste concrete; use a 0.125mm sieve to screen the broken waste concrete particles, larger than The 0.125mm waste concrete particles are subjected to secondary crushing until the waste concrete powder smaller than 74um is obtained; the waste concrete powder and clay waste are respectively placed in a ball mill for grinding at a power of 50-100kW for 2 hours until all The particle sizes are all less than 40um. The obtained waste concrete powder and clay powder are placed in a 5L plastic mixing tank according to the mass ratio of 3:1, and processed in the mixer for 12 hours at a speed of 300r / min. For the mixture, mix the mixture and absolute ethanol uniformly according to the solid-to-liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com