Y-doped Mg alloy and preparation method thereof

A technology of magnesium alloy and alloy powder, applied in the field of yttrium-doped magnesium alloy and its preparation, can solve the problems of stress corrosion cracking, low strength and ductility, affecting the application effect and service life of magnesium-lithium alloy, etc. The effect of body sticking cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

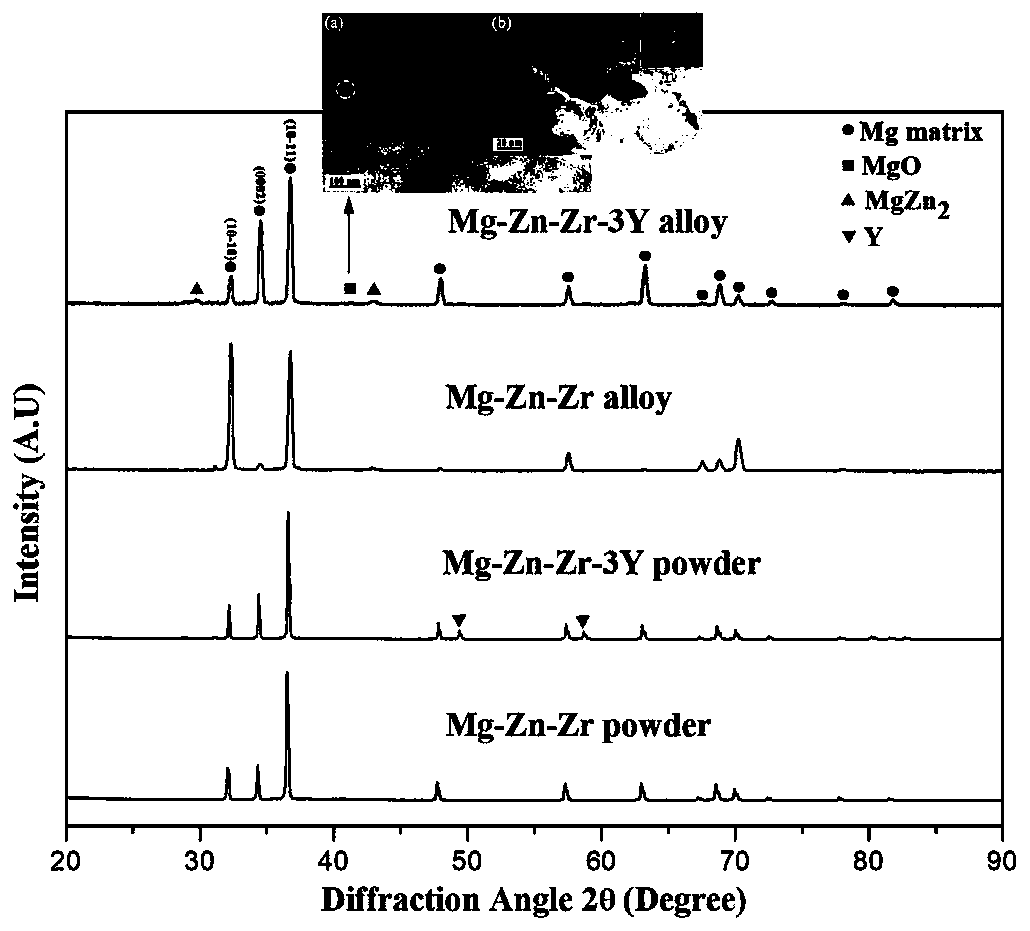

[0043] Magnesium alloy doped with yttrium, composed of Mg, Zn, Zr and Y; the mass of each component in 100g magnesium alloy is Zn: 4.9g; Zr: 0.16g; Y: 2.9g; the balance is Mg and unavoidable impurities .

[0044] Preparation:

[0045] (1) Preparation of alloy powder: first weigh 97.1gMg-4.9wt.%Zn-0.16wt.%Zr powder and 2.9gY powder (purity is 99.9%, nano-scale particle size) into a mechanical ball mill jar, then add 0.05g ethanol , then add 1g of zinc stearate, evacuate to a vacuum of 1Pa, then pass in argon for 10s, add 2kg of stainless steel balls with a particle size of 5mm, then adjust the revolution speed to 150r / min, first rotate forward for 15min, and then stop for 20min , then reversed for 15 minutes, paused for 20 minutes, and circulated ball milled for 10 hours to obtain alloy powder;

[0046] (2) Sintering: Use a vacuum hot-pressing sintering furnace for high-temperature pressureless sintering. First, put the alloy powder obtained in step (1) into the mold, then in...

Embodiment 2

[0049] Magnesium alloy doped with yttrium, composed of Mg, Zn, Zr and Y; the mass of each component in 100g magnesium alloy is Zn: 5.5g; Zr: 0.19g; Y: 3.2g; the balance is Mg and unavoidable impurities .

[0050] Preparation:

[0051] (1) Preparation of alloy powder: first weigh 96.8gMg-5.5wt.%Zn-0.19wt.%Zr powder and 3.2gY powder (purity is 99.9%, nano-scale particle size) into a mechanical ball mill jar, then add 0.15g ethanol , then add 2g of zinc stearate, vacuumize to a vacuum degree of 2Pa, then pass in argon for 15s, add 2kg of stainless steel balls with a particle size of 8mm, then adjust the revolution speed to 260r / min, first rotate forward for 20min, and then stop for 30min , then reversed for 20 minutes, paused for 30 minutes, and circulated ball milled for 14 hours to obtain alloy powder;

[0052] (2) Sintering: Use a vacuum hot-pressing sintering furnace for high-temperature pressureless sintering. First, put the alloy powder obtained in step (1) into the mold,...

Embodiment 3

[0055] The magnesium alloy doped with yttrium is composed of Mg, Zn, Zr and Y; the mass of each component in 100g magnesium alloy is Zn: 5.1g; Zr: 0.18g; Y: 3g; the balance is Mg and unavoidable impurities.

[0056] Preparation:

[0057] (1) Preparation of alloy powder: first weigh 97gMg-5.1wt.%Zn-0.18wt.%Zr powder and 3gY powder (purity is 99.9%, nano-scale particle size) and put it into a mechanical ball mill jar, then add 0.1g ethanol, and then Add 2g of zinc stearate, evacuate to a vacuum degree of 1Pa, then pass in argon gas for 12s, add 2kg of stainless steel balls with a particle size of 10mm, then adjust the revolution speed to 200r / min, first rotate forward for 20min, pause for 25min, and then Reverse for 20 minutes, stop for 25 minutes, and circulate the ball mill for 12 hours to obtain alloy powder;

[0058] (2) Sintering: Use a vacuum hot-pressing sintering furnace for high-temperature pressureless sintering. First, put the alloy powder obtained in step (1) into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Tensile yield strength | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com