PE plastic pipeline manufacturing process

A technology of plastic pipes and manufacturing processes, which is applied to tubular objects, other household appliances, household appliances, etc. It can solve the problems that the strength of PE pipes cannot meet the requirements, affect the stability of material performance, shorten the service life, etc., and achieve improved surface activity. energy, improve overall performance, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

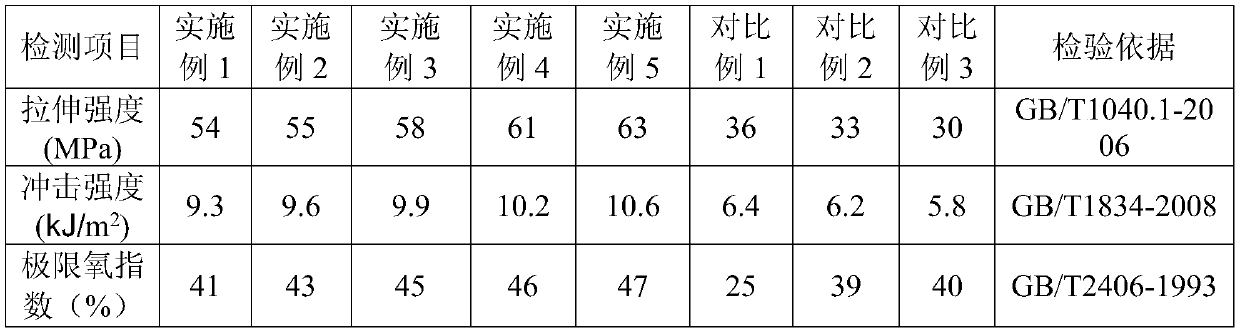

Examples

Embodiment 1

[0033] A PE plastic pipe manufacturing process is characterized in that it comprises the steps of:

[0034] Step S1, preparation of the copolymer: 2-(trimethylsilyl)ethyleneboronic acid pinacol ester, perfluoroallyl benzene, 6-allyl-1,3,5-triazine-2,4 -diamine, 5-(vinyloxy)-1,3-adamantanediol, and azobisisobutyronitrile were added to dimethyl sulfoxide, stirred and reacted at 65°C for 4 hours in a nitrogen atmosphere, and then Precipitate in water, wash the precipitated polymer 3 times with ethanol, and then dry it in a vacuum oven at 80°C to a constant weight to obtain a copolymer; the 2-(trimethylsilyl)vinylboronic acid pinacol ester , perfluoroallylbenzene, 6-allyl-1,3,5-triazine-2,4-diamine, 5-(vinyloxy)-1,3-adamantanediol, azo The mass ratio of diisobutyronitrile and dimethylsulfoxide is 1:2:1:1:0.04:15;

[0035] Step S2, mixing: the copolymer prepared in step S1, waste polyethylene, PE resin, ultra-high molecular weight polyethylene fiber, nano-boron fiber, silane coup...

Embodiment 2

[0041] A PE plastic pipe manufacturing process is characterized in that it comprises the steps of:

[0042] Step S1, preparation of the copolymer: 2-(trimethylsilyl)ethyleneboronic acid pinacol ester, perfluoroallyl benzene, 6-allyl-1,3,5-triazine-2,4 -Diamine, 5-(vinyloxy)-1,3-adamantanediol, and azobisisoheptanonitrile were added to N,N-dimethylformamide, stirred at 67°C in a helium atmosphere After reacting for 5 hours, it precipitated in water, washed the precipitated polymer 4 times with ethanol, and then dried it in a vacuum oven at 83°C to a constant weight to obtain a copolymer; the 2-(trimethylsilyl) Vinylboronic acid pinacol ester, perfluoroallylbenzene, 6-allyl-1,3,5-triazine-2,4-diamine, 5-(vinyloxy)-1,3-adamantine The mass ratio of alkanediol, azobisisoheptanonitrile, and N,N-dimethylformamide is 1:2:1:1:0.045:17;

[0043] Step S2, mixing: the copolymer prepared in step S1, waste polypropylene, PE resin, ultra-high molecular weight polyethylene fiber, nano-boron...

Embodiment 3

[0049] A PE plastic pipe manufacturing process is characterized in that it comprises the steps of:

[0050] Step S1, preparation of the copolymer: 2-(trimethylsilyl)ethyleneboronic acid pinacol ester, perfluoroallyl benzene, 6-allyl-1,3,5-triazine-2,4 -Diamine, 5-(vinyloxy)-1,3-adamantanediol, and azobisisoheptanonitrile were added to N,N-dimethylacetamide, stirred at 70°C in a neon atmosphere Reacted for 5.5 hours, then precipitated in water, and washed the precipitated polymer 5 times with ethanol, and then dried to constant weight in a vacuum oven at 85°C to obtain a copolymer; the 2-(trimethylsilyl) Vinylboronic acid pinacol ester, perfluoroallylbenzene, 6-allyl-1,3,5-triazine-2,4-diamine, 5-(vinyloxy)-1,3-adamantine The mass ratio of alkanediol, azobisisoheptanonitrile and N,N-dimethylacetamide is 1:2:1:1:0.05:20;

[0051] Step S2, mixing: the copolymer prepared in step S1, waste polyvinyl chloride, PE resin, ultra-high molecular weight polyethylene fiber, nano-boron fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com