Si-Y-C ternary ceramic matrix composite material and preparation method

A technology of ternary ceramics and composite materials, which is applied in the field of composite materials to improve the water and oxygen corrosion resistance and ablation resistance of ceramic matrix composite materials, can solve the problems of incapability of large-scale production, high preparation temperature and long preparation cycle, and achieve equipment The effect of low requirements, low preparation temperature and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

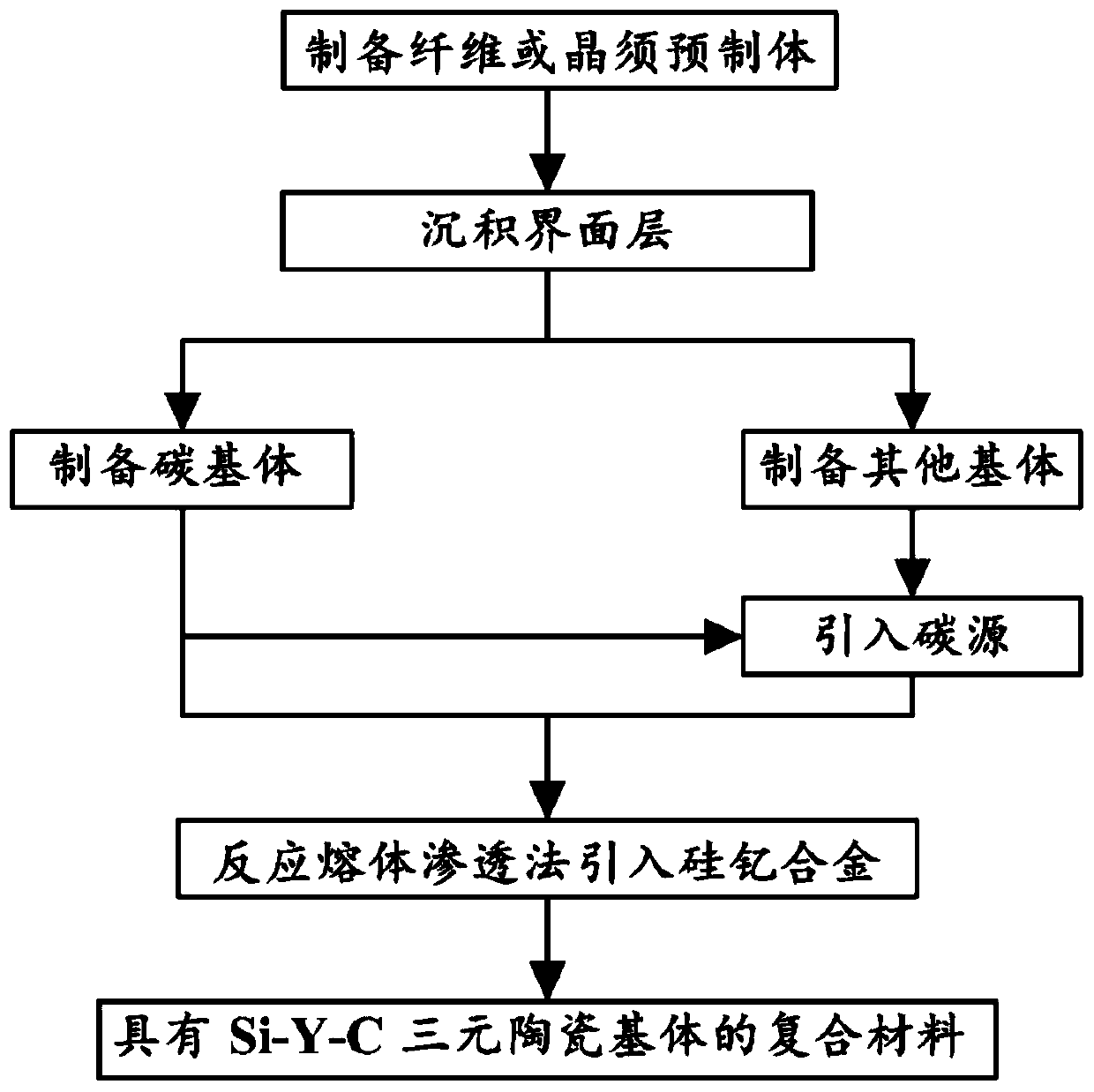

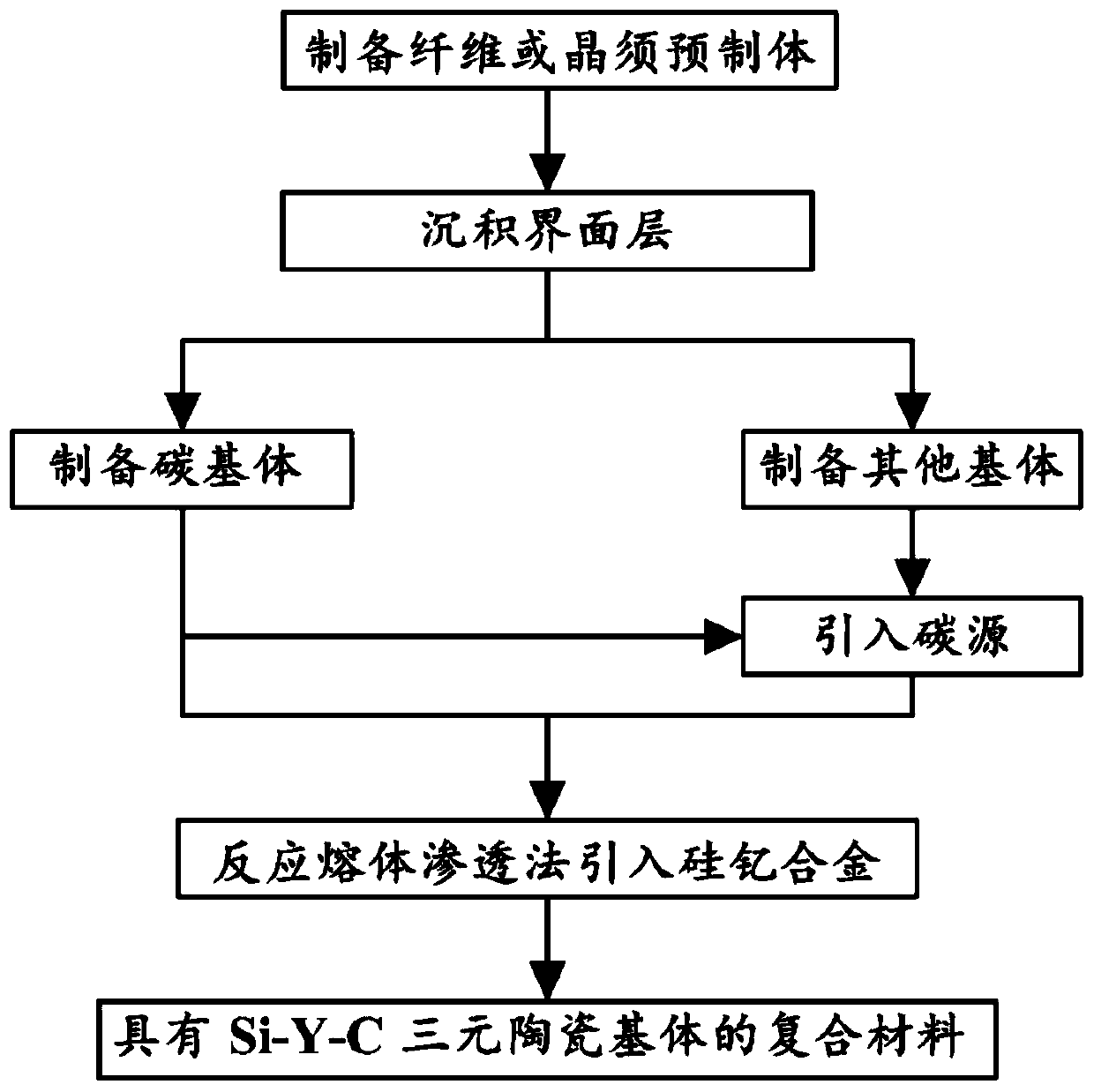

Method used

Image

Examples

Embodiment 1

[0051] Step 1. Preparation of fiber preform: 0° non-woven fabric, tire mesh, 90° non-woven fabric, and tire mesh are successively superimposed to the thickness of the carbon fiber preform, and the carbon fiber preform is prepared by relay needle punching.

[0052] Step 2. Deposition of the interface layer: The pyrolytic carbon interface layer is deposited on the carbon fiber preform by chemical vapor infiltration.

[0053] Step 3. Preparation of matrix: with propylene (C 3 H 6 ) is the gas source, Ar gas is the diluent gas, the deposition temperature of the CVI process is 900 °C, the deposition time is 500 h, and the system pressure is 5 kPa, to obtain a sample with an open porosity of 18.5%.

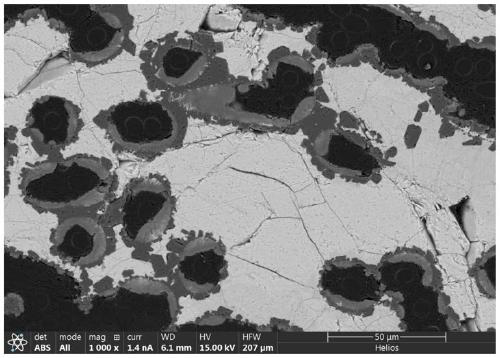

[0054] Step 4. Introducing silicon-yttrium alloy by reactive melt infiltration method: The composite material and the silicon-yttrium alloy are placed in a graphite box, and the contact method adopts a one-way method. Put the graphite box into a graphite crucible with an inner diamete...

Embodiment 2

[0056] Step 1. Preparation of fiber preform: 0° non-woven fabric, tire mesh, 90° non-woven fabric, and tire mesh are successively superimposed to the thickness of the carbon fiber preform, and the carbon fiber preform is prepared by relay needle punching.

[0057] Step 2. Deposition of the interface layer: The pyrolytic carbon interface layer is deposited on the carbon fiber preform by chemical vapor infiltration.

[0058] Step 3: Preparation of matrix: with propylene (C 3 H 6 ) is the gas source, Ar gas is the diluent gas, the deposition temperature of the CVI process is 900 °C, the deposition time is 500 h, and the system pressure is 5 kPa, to obtain a sample with an open porosity of 19.9%.

[0059] Step 4. Introducing silicon-yttrium alloy by reactive melt infiltration method: The composite material and the silicon-yttrium alloy are placed in a graphite box, and the contact method adopts the embedding method. Put the graphite box into a graphite crucible with an inner dia...

Embodiment 3

[0061] Step 1. Preparing a fiber preform: After cutting the silicon carbide plain fiber cloth into a suitable size, lamination, and shaping with a graphite mold to prepare a silicon carbide fiber preform.

[0062] Step 2. Deposition of interface layer: A boron nitride interface layer is deposited on the carbon fiber preform by chemical vapor infiltration.

[0063] Step 3. Preparation of substrate: with trichloromethylsilane (CH 3 SiCl 3 , MTS) is the gas source, Ar is the diluent gas, and H is used by bubbling 2 As the carrier gas, MTS was brought into the reactor, the deposition temperature was 1050°C, the total system pressure was 5kPa, H 2 The molar ratio to MTS is 10:1, and the chemical reaction for preparing SiC is: CH 3 SiCl 3 +H 2 →SiC+HCl. A sample with an open porosity of 24.6% was obtained by depositing several heats.

[0064] Step 4. Introducing the carbon source: Mix the phenolic resin and absolute ethanol in a mass ratio of 3:10, and stir magnetically for 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com