Corona-resistant polyimide film and preparation method thereof

A technology of polyimide film and corona resistance, which is applied in the direction of flat products, other household utensils, applications, etc., and can solve the problems of low adhesion between the film and the substrate, easy agglomeration and settlement, and low surface of the film, so as to avoid Effects of secondary agglomeration and settlement, improvement of corona resistance performance, and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

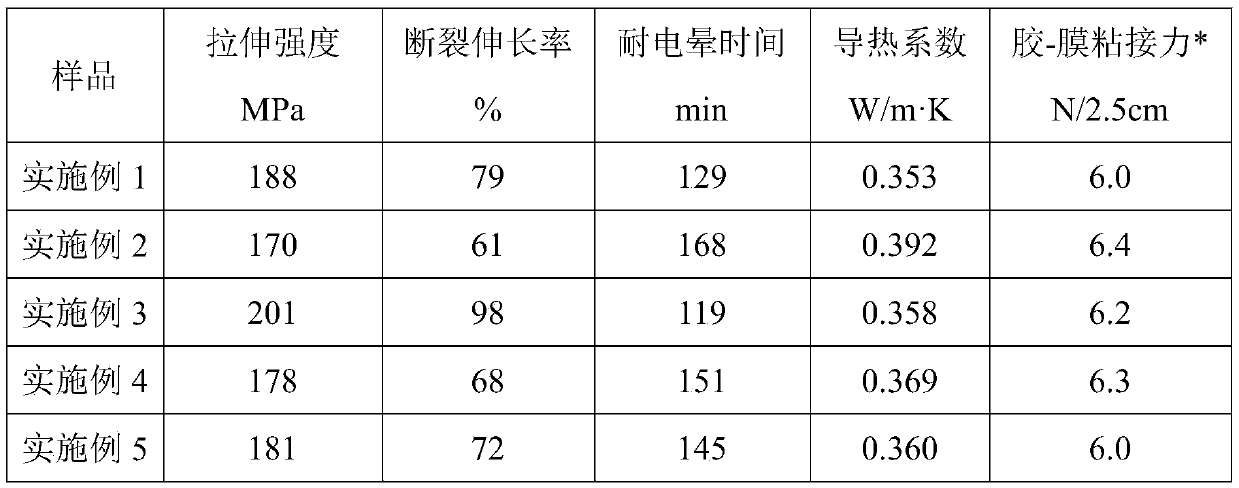

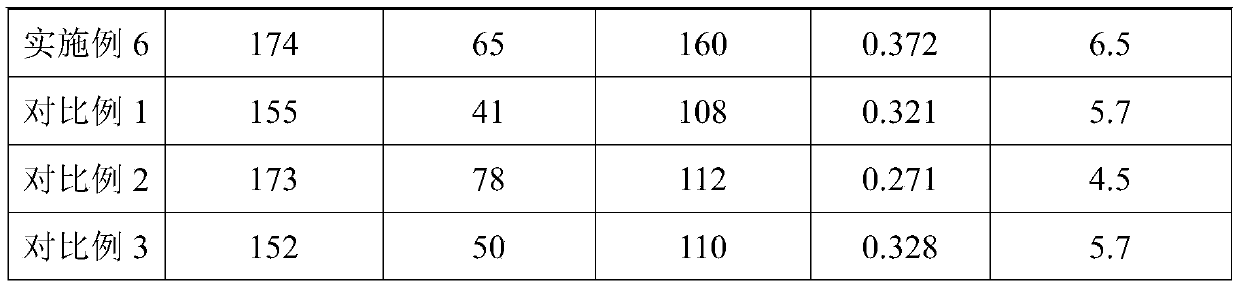

Examples

Embodiment 1

[0033] A kind of preparation method of anti-corona polyimide film of the present invention, comprises the following steps:

[0034] (1) At 10°C, disperse 20.2kg of alumina (first inorganic particle), 0.12kg of titanium oxide (second inorganic particle), and 0.65kg of silane coupling agent in 82.17kg of DMAc at high speed, wherein the particle size of alumina is 50nm, and the particle size of titanium oxide is 700nm to obtain nano slurry;

[0035] (2) Add 138kg acetic anhydride and 16.65kg pyridine to 101.85kg nano slurry, stir and mix evenly to obtain nano hybrid solution;

[0036] (3) at room temperature, under nitrogen protection, 43.51kg ODA is dissolved in 362.1kg DMAc, then add 47.42kg PMDA in batches, carry out polycondensation reaction, obtain polyamic acid resin, resin viscosity reaches 1550 poise, defoaming stand-by;

[0037] (4) At -18°C, mix the nano-hybrid solution after step (2) and the polyamic acid resin after (3) evenly to obtain a precursor resin with a visco...

Embodiment 2

[0039] A kind of preparation method of anti-corona polyimide film of the present invention, comprises the following steps:

[0040](1) At 35°C, 20.1kg alumina (first inorganic particle), 10kg silicon oxide (first inorganic particle), 0.66kg silicon oxide (second inorganic particle), 1.4kg titanate coupling agent Dispersed in 96.18kg DMF, wherein the particle size of alumina is 20nm, the particle size of silicon oxide of the first inorganic particle is 30nm, and the particle size of silicon oxide of the second inorganic particle is 1000nm, to obtain a nano slurry;

[0041] (2) Add 85.27kg of propionic anhydride and 18.21kg of 2-picoline in 128kg of nano slurry, stir and mix evenly to obtain a nano-hybrid solution;

[0042] (3) at room temperature, under nitrogen protection, the ODA of 30.5kg is dissolved in 277kg DMF, then adds 33.1kg PMDA in batches, carries out polycondensation reaction, obtains polyamic acid resin, and resin viscosity reaches 1610 poises, defoaming stand-by ...

Embodiment 3

[0045] A kind of preparation method of anti-corona polyimide film of the present invention, comprises the following steps:

[0046] (1) At 5°C, 16kg alumina (first inorganic particle), 3.8kg titanium oxide (first inorganic particle), 0.4kg silicon carbide (second inorganic particle), 1.6kg aluminate coupling agent Disperse in 105kg DMF, wherein the particle size of alumina is 160nm, the particle size of titanium oxide is 50nm, and the particle size of silicon carbide is 800nm, to obtain nano slurry;

[0047] (2) Add 139.8kg acetyl chloride and 13.54kg isoquinoline to 126kg nano slurry, stir and mix evenly to obtain nano hybrid solution;

[0048] (3) at room temperature, under nitrogen protection, the ODA of 65.12kg is dissolved in the DMF of 435kg, then adds 67.02kg PMDA in batches, carries out polycondensation reaction, obtains polyamic acid resin, and resin viscosity reaches 1610 poises, defoaming waits for use;

[0049] (4) At 0°C, mix the nano-hybrid solution after step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com