Aluminum alloy conductor flexible cable and preparation method thereof

A technology of aluminum alloy conductors and flexible cables, which is applied in the direction of metal/alloy conductors, cable/conductor manufacturing, conductors, etc., can solve the problems that flexible cables cannot use aluminum alloy as conductors, etc., and achieve uniform force balance and good corona resistance Flexible, easy-to-bend effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

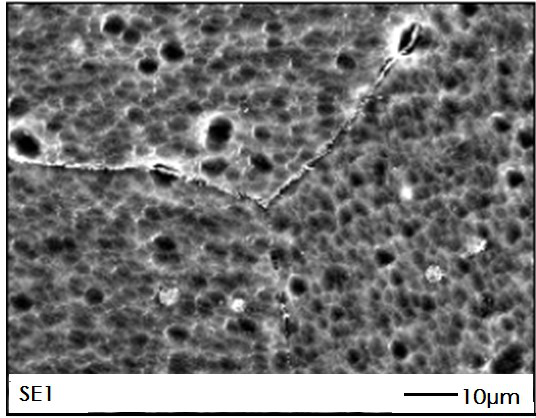

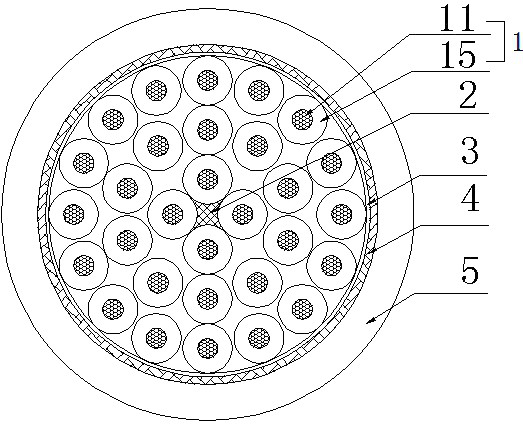

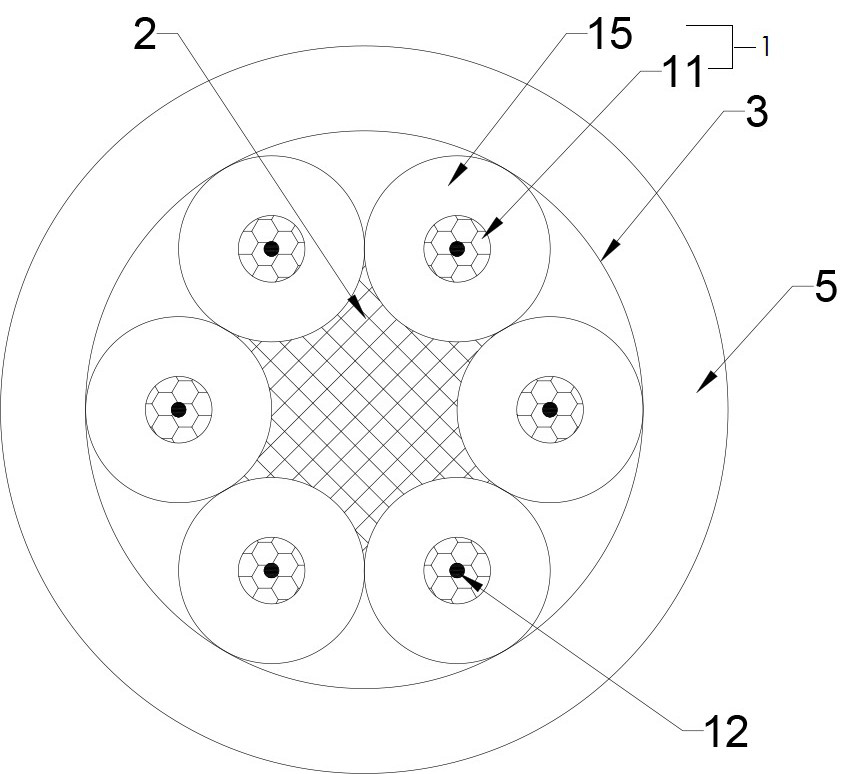

Method used

Image

Examples

Embodiment 1

[0034] S1 material preparation: Weigh raw materials according to the ratio of Example 1 in Table 1: 0.1wt% magnesium ingot, 0.4wt% AlSi20 master alloy, 0.15wt% AlFe20 master alloy, 0.05wt% AlCu50 master alloy, 0.785wt% AlB3 master alloy, AlTi1 .2B0.5 master alloy 0.25wt%, AlRE10 aluminum rare earth master alloy 0.3wt%, the rest is aluminum ingots with a purity of 99.70%, and the raw materials are dried in a drying oven at a drying temperature of 110°C and a drying time of 6 hours;

[0035] Among them, the magnesium ingot was purchased from Shaanxi Tianyu Magnesium Industry Group Co., Ltd., the AlSi20 master alloy was purchased from Sichuan Lande High-Tech Industry Co., Ltd., the AlFe20 master alloy was purchased from Sichuan Lande High-Tech Industry Co., Ltd., and the AlCu50 master alloy was purchased from Sichuan Lande High-tech Industry Co., Ltd., AlB3 master alloy was purchased from Sichuan Lande High-Tech Industry Co., Ltd., AlTi1.2B0.5 master alloy was purchased from Sishu...

Embodiment 2

[0042] S1 material preparation: Weigh raw materials according to the ratio of Table 1 Example 2: 0.25wt% magnesium ingot, 0.6wt% AlSi20 master alloy, 1.25wt% AlFe20 master alloy, 0.1wt% AlCu50 master alloy, 1.05wt% AlB3 master alloy, AlB5Ti1 Master alloy 0.25wt%, AlRE10 aluminum rare earth master alloy 0.3wt%, the rest is aluminum ingots with a purity of 99.70%, and the raw materials are dried in a drying oven at a drying temperature of 140°C and a drying time of 5 hours;

[0043]Among them, the magnesium ingot was purchased from Shaanxi Tianyu Magnesium Industry Group Co., Ltd., the AlSi20 master alloy was purchased from Sichuan Lande High-Tech Industry Co., Ltd., the AlFe20 master alloy was purchased from Sichuan Lande High-Tech Industry Co., Ltd., and the AlCu50 master alloy was purchased from Sichuan Lande High-tech Industry Co., Ltd., AlB3 master alloy was purchased from Sichuan Lande High-Tech Industry Co., Ltd., AlB5Ti1 master alloy was purchased from Shandong Binzhou Hu...

Embodiment 3

[0049] S1 material preparation: weighing raw materials according to the ratio of Table 1 Example 3: 0.45 wt% magnesium ingot, 1.5wt% AlSi20 master alloy, 0.75wt% AlFe20 master alloy, 0.2wt% AlCu50 master alloy, 1.5wt% AlB3 master alloy, AlTi40 Master alloy 0.1wt%, AlRE10 aluminum rare earth master alloy 0.1wt%, the rest is aluminum ingots with a purity of 99.70%, and the raw materials are dried in a drying oven at a drying temperature of 80-150°C and a drying time of 5-10h;

[0050] Among them, the magnesium ingot was purchased from Shaanxi Tianyu Magnesium Industry Group Co., Ltd., the AlSi20 master alloy was purchased from Sichuan Lande High-Tech Industry Co., Ltd., the AlFe20 master alloy was purchased from Sichuan Lande High-Tech Industry Co., Ltd., and the AlCu50 master alloy was purchased from Sichuan Lande High-tech Industry Co., Ltd., AlB3 master alloy was purchased from Sichuan Lande High-tech Industry Co., Ltd., AlTi40 master alloy was purchased from Sichuan Lande Hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com