Ethylene-propylene rubber insulating mouse-proof insect-proof low-smoke halogen-free flame-retardant direct-current high-voltage cable insulating material used for rail traffic

An ethylene-propylene rubber insulation and rail transit technology, applied in the direction of rubber insulators, insulators, organic insulators, etc., can solve problems such as high cost, cable breakdown, and human health hazards, so as to ensure processing performance, mechanical performance, and electrical insulation performance and stability, the effect of improving the electrical insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

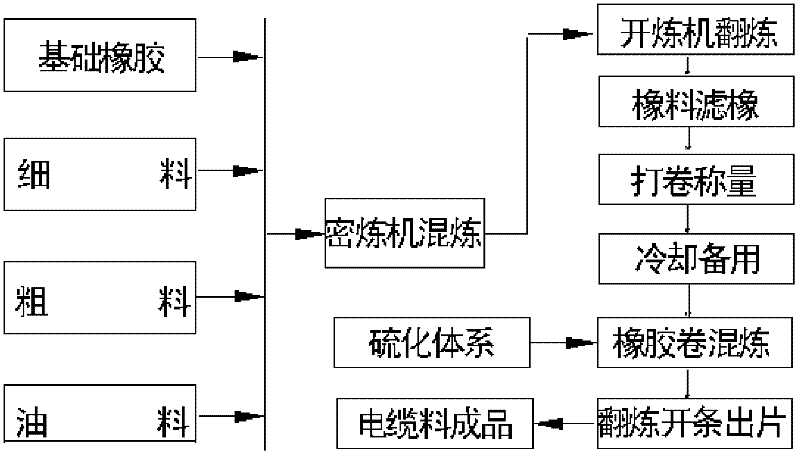

Method used

Image

Examples

Embodiment

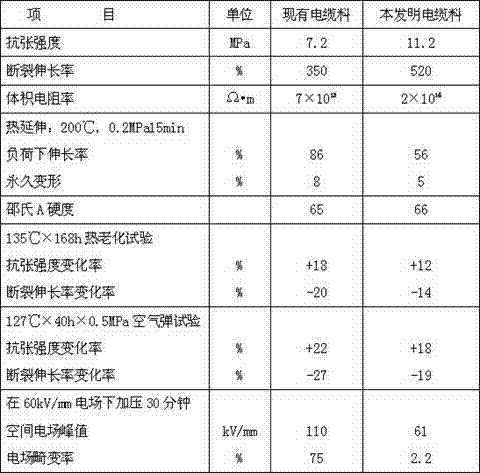

[0030] Embodiment proportioning is shown in Table 2. Prepare and weigh various materials according to the ratio in Table 2. First, put ethylene-propylene rubber into the internal mixer for 30 seconds to 1 minute, then add microcrystalline paraffin, zinc oxide nanopowder, anti-aging agent 264, red lead, low-density Polyethylene and other materials, magnesium oxide nanopowder, epoxy soybean oil, after mixing for about 2 minutes, add the reinforcing agent clay and mix for about 3 minutes. The temperature of the mixing room is controlled at 120-135 ° C. Vulcanizing agent and coupling agent are kneaded for 1 minute to make a rubber sheet with a thickness of 1-2 mm for later use.

[0031] Embodiment formula table 2

[0032] raw material Example 1 Example 2 Example 3 Ethylene Propylene Rubber 100 100 100 Vulcanizing agent 2.3 2.8 3.2 co-vulcanizing agent 1.2 0.7 0.3 Reinforcing agent 65 58 50 Microcrystalline Paraffin 7 6 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com