Preparation method of woodworking tool

A tool and woodworking technology, applied in the field of woodworking tool preparation, can solve the problems of insufficient bonding force between the diamond coating and the tool substrate, reduced tool life, high friction coefficient, etc., to meet the characteristic requirements, improve the bonding force, and good wear resistance and cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In the preparation method of the woodworking tool of the present invention, the woodworking tool is a non-regrinding woodworking tool or an indexable and transferable woodworking tool.

[0034] In the preparation method of the woodworking cutter of the present invention, the cemented carbide is a cobalt-containing cemented carbide.

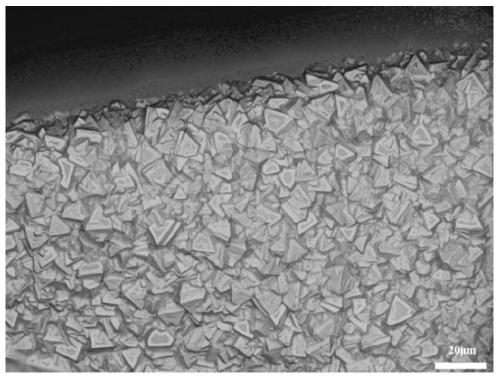

[0035] In the preparation method of the woodworking cutter of the present invention, after alkali etching the cemented carbide, it is cleaned with deionized water, and then acid-etched, and after acid-etched, it is cleaned with deionized water to obtain a pretreated tool substrate.

[0036] In the preparation method of the woodworking cutter of the present invention, the cutter substrate is placed in a diamond suspension for ultrasonic treatment, that is, the cutter substrate is seeded.

[0037] In the preparation method of the woodworking tool of the present invention, the particle size of the diamond in the diamond suspension is 50-500 nm...

Embodiment 1

[0041] The preparation method of the woodworking cutter of the present embodiment comprises the following steps:

[0042] (1) Pretreatment

[0043] Put the tungsten-cobalt alloy in the alkaline solution for alkaline etching, the alkaline etching time is 10min, the alkaline solution is NaOH, K with a weight ratio of 1:1:20 3 [Fe(CN) 6 ] and H 2 O mixed solution, after alkaline etching, use deionized water to clean. The content of cobalt in the tungsten-cobalt alloy is 10wt%.

[0044] Put the tungsten-cobalt alloy after alkaline etching and cleaning into acid solution for acid etching. The acid etching time is 10s. Cleaning with deionized water to obtain a decobaltized cutting tool substrate.

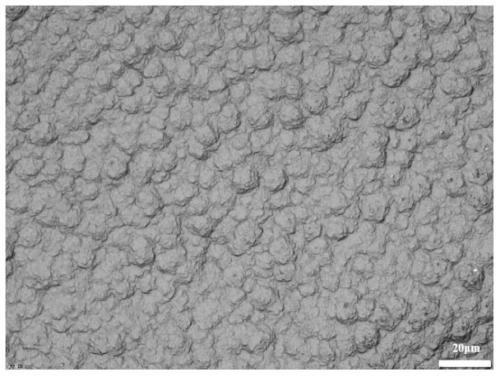

[0045] (2) Seed crystal

[0046] The decobaltized tool base obtained in step (1) is placed in a diamond suspension for ultrasonic treatment for 10 minutes, and then dried at 100° C. for 30 minutes.

[0047] The diamond suspension is composed of diamond powder, corundum powder and w...

Embodiment 2

[0053] The preparation method of the woodworking cutter of the present embodiment comprises the following steps:

[0054] (1) Pretreatment

[0055] Put the tungsten-cobalt alloy in the alkaline solution for alkaline etching, the alkaline etching time is 30min, the alkaline solution is NaOH, K with a weight ratio of 1:1:15 3 [Fe(CN) 6 ] and H 2 O mixed solution, after alkaline etching, use deionized water to clean. The content of cobalt in the tungsten-cobalt alloy is 3wt%.

[0056] Put the tungsten-cobalt alloy after alkaline etching and cleaning into the acid solution for acid etching. The acid etching time is 80s. The acid solution is a mixture of sulfuric acid, hydrogen peroxide and water with a volume ratio of 1:15:95. After acid etching, use Cleaning with deionized water to obtain a decobaltized cutting tool substrate.

[0057] (2) Seed crystal

[0058] The decobaltized tool base obtained in step (1) was placed in a diamond suspension for ultrasonic treatment for 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com