A kind of waterborne two-component paint with high impact resistance and its application

A water-based two-component, impact-resistant technology, used in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as uncontrollable, limited epoxy resin content, and inability to fully meet impact resistance and corrosion resistance. Achieve the effect of improving impact resistance and obtaining a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

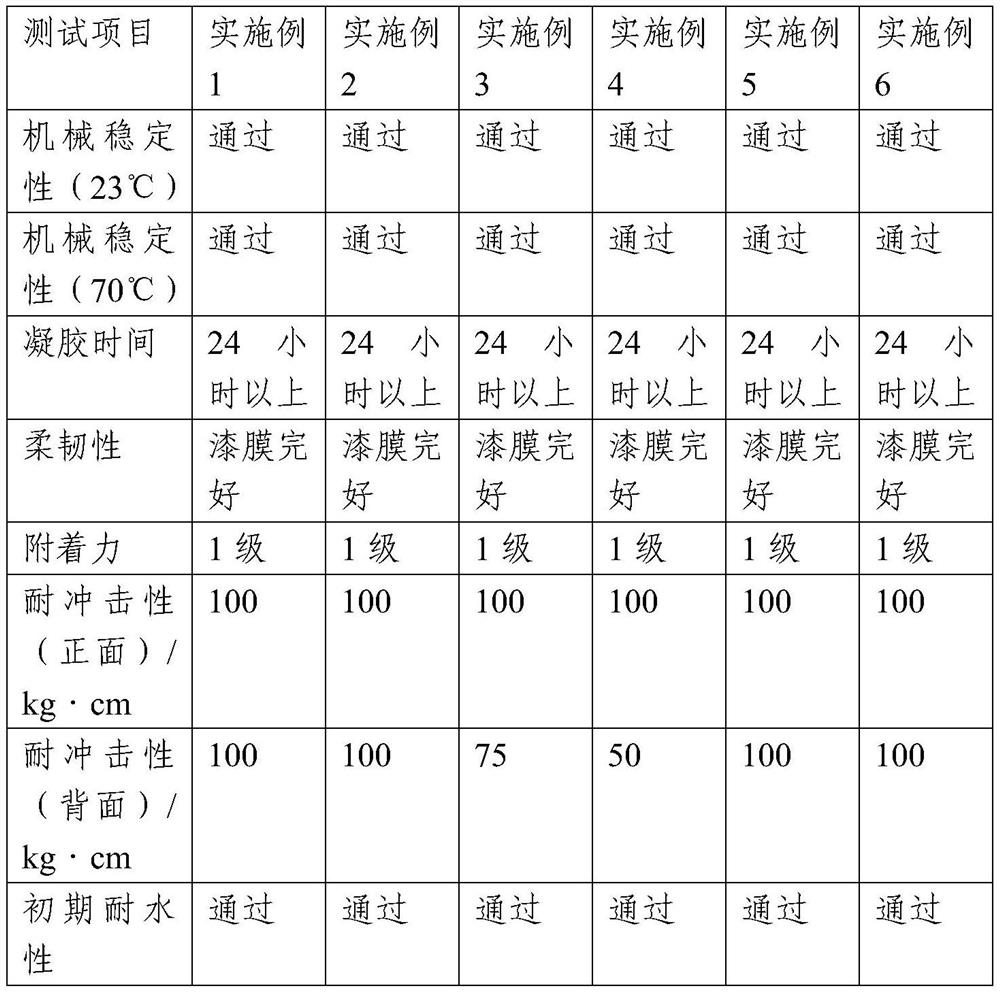

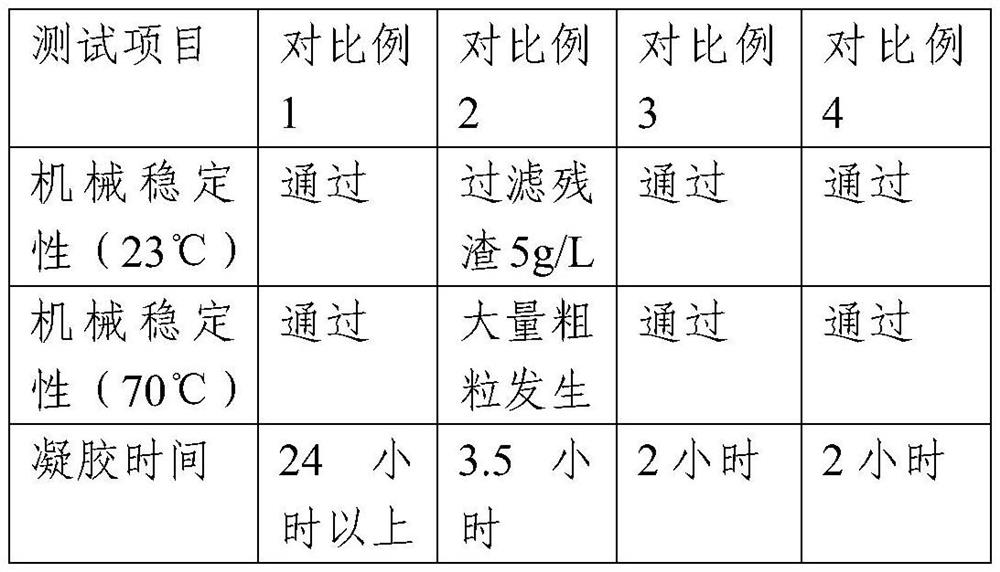

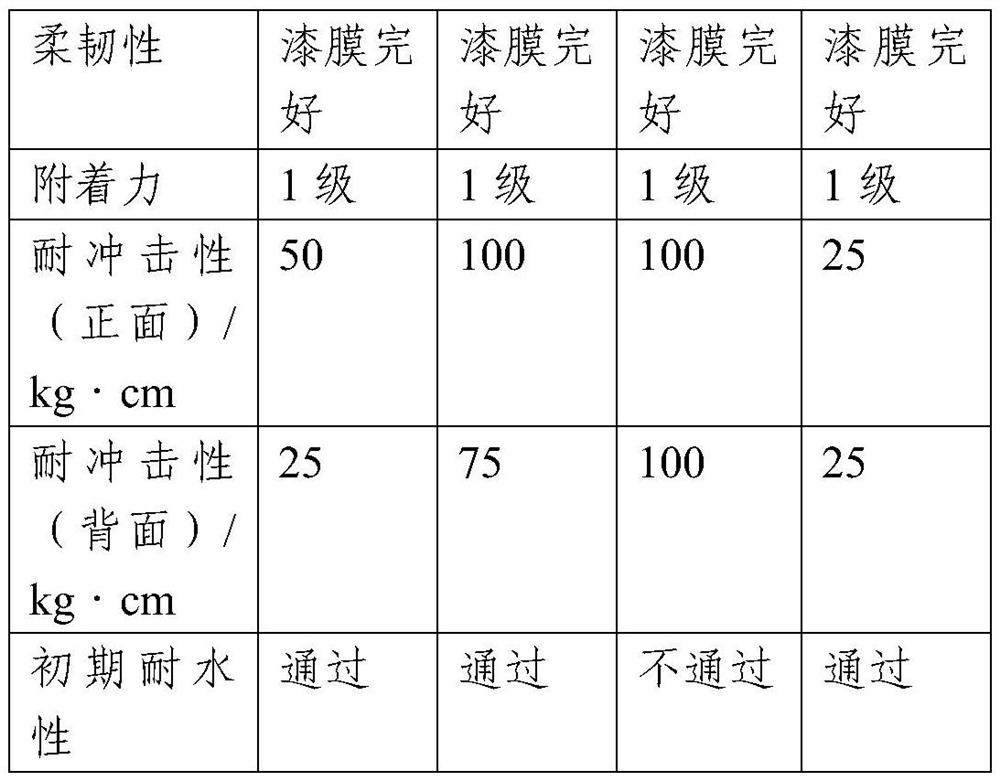

Examples

Embodiment 1

[0037] The present embodiment provides a water-based two-component paint, comprising a composite emulsion and a curing agent with a weight ratio of 8:1, and the composite emulsion includes the following components by weight: 0.2 parts of thickener (Aidike UH- 420), 0.2 parts of ammonia water, 0.7 parts of dispersant (Santa Nopco SN-5040), 0.1 part of defoamer (BASF WBA), 8 parts of iron oxide, 7 parts of mica powder, 0.8 parts of titanium dioxide, 48 parts of water-based ring Oxygen emulsion, 12 parts of water-based acrylic emulsion, 1 part of film-forming aid; the curing agent is polyamide resin.

[0038] Wherein, the water-based epoxy emulsion is a bisphenol A type epoxy resin emulsion; the water-based acrylic emulsion uses butyl acrylate, isooctyl acrylate, methacrylic acid, styrene, and hydroxyethyl acrylate as monomers, Among them, methacrylic acid accounts for 1wt%, hydroxyethyl acrylate accounts for 1wt%, and the proportion of other soft and hard monomers is adjusted. T...

Embodiment 2

[0041]This embodiment provides a water-based two-component paint. The difference from Example 1 is that the water-based acrylic emulsion uses polyoxyethylene alkyl ether emulsifier and allyloxy nonylphenol polyoxyethylene ether ammonium sulfate As the emulsifier, wherein, by weight percentage, the usage amount of allyloxynonylphenol polyoxyethylene ether ammonium sulfate is 15wt% of the total amount of the emulsifier.

[0042] The preparation method of this water-based two-component paint is the same as in Example 1.

Embodiment 3

[0044] The present embodiment provides a water-based two-component paint, and the difference from Example 1 is: the weight ratio of the water-based epoxy emulsion and the water-based acrylic emulsion is adjusted to 6.5:1, that is, 52 parts of water-based epoxy emulsion, 8 water-based acrylic emulsion.

[0045] The preparation method of this water-based two-component paint is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com