Composite scale inhibition and corrosion inhibitor and applications in low-hardness water

A scale and corrosion inhibitor, condensation reaction technology, used in scale removal and water softening, water/sludge/sewage treatment, special treatment targets, etc. The problem of high content is to achieve the effect of less components, good corrosion and scale inhibition effect, and improved corrosion inhibition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

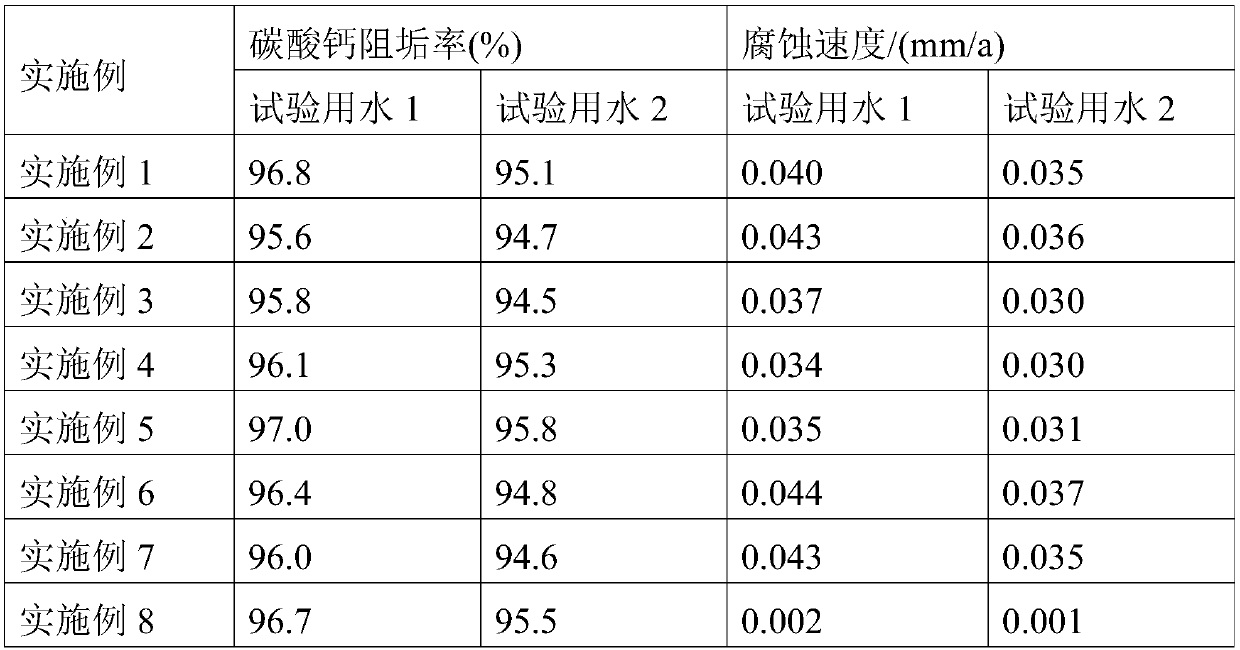

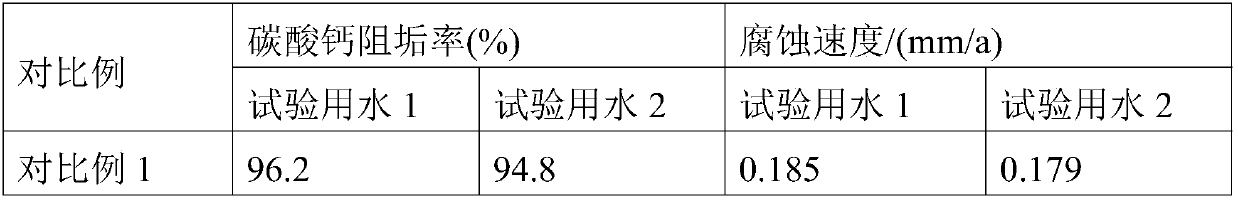

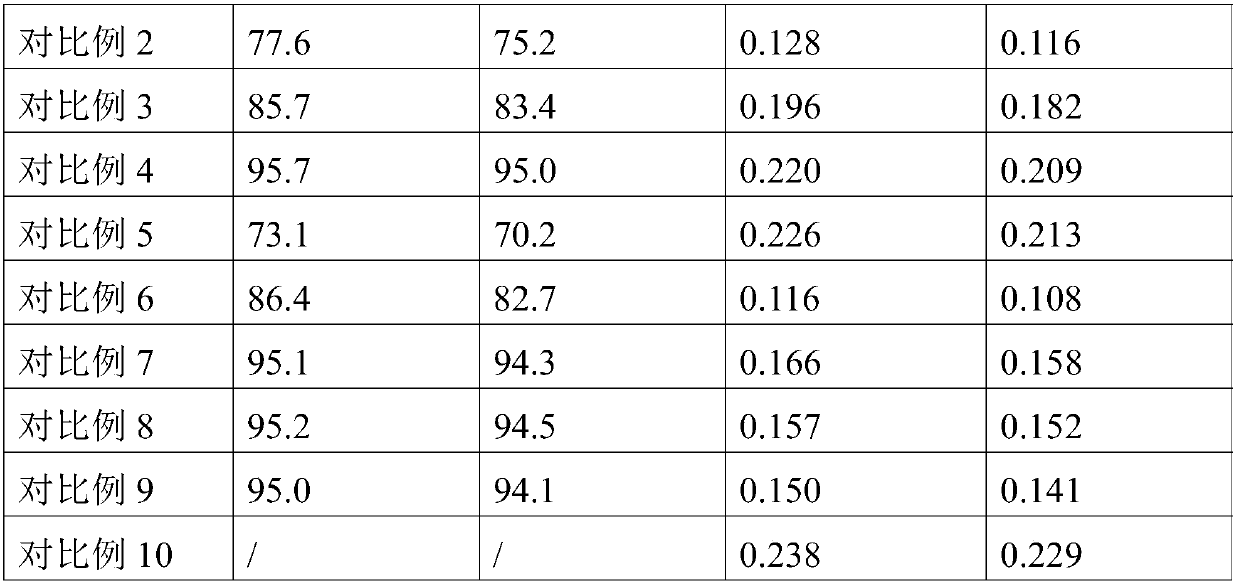

Examples

preparation example 1

[0065] Prepare the condensation reaction product of sodium gluconate and triethanolamine: add 32.7g (0.15mol) sodium gluconate, 14.9g (0.1mol) triethanolamine and 100mL water in the four-neck flask equipped with stirrer, distillation unit and thermometer, Start stirring, so that sodium gluconate and triethanolamine are fully dissolved and mixed. After that, add 5g (0.05mol) of concentrated sulfuric acid at 20°C, heat the oil bath (simethicone oil) to 130°C, react for 6 hours, distill 40g of water, and cool the remaining liquid to obtain the condensation of sodium gluconate and triethanolamine The reaction product has a solid content of 40% by weight and a molecular weight distribution of 327-683.

preparation example 2

[0067] Prepare the condensation reaction product of sodium gluconate and triethanolamine: add 32.7g (0.15mol) sodium gluconate, 134.1g (0.9mol) triethanolamine and 100mL water in the four-neck flask equipped with stirrer, distillation unit and thermometer, Start stirring, so that sodium gluconate and triethanolamine are fully dissolved and mixed. Afterwards, 45 g (containing H 2 SO 4 , 0.45mol) concentrated sulfuric acid, heated to 130°C in an oil bath (simethicone oil), reacted for 6 hours, distilled 50g of water, and cooled the remaining liquid to obtain the condensation reaction product of sodium gluconate and triethanolamine. After determination, its solid The content is 59.6% by weight, and its molecular weight is 327.

preparation example 3

[0069] Prepare the condensation reaction product of potassium gluconate and triethanolamine: add 23.4g (0.1mol) potassium gluconate, 2.3g (0.015mol) triethanolamine and 100mL water in the four-neck flask equipped with stirrer, distillation unit and thermometer, Start stirring, so that sodium gluconate and triethanolamine are fully dissolved and mixed. Afterwards, 3.15 g (containing HNO 3 ,0.034mol) concentrated nitric acid, heated to 110°C in an oil bath (simethicone oil), reacted for 2 hours, the amount of water evaporated was 25g, and the remaining liquid was cooled to obtain the condensation reaction product of potassium gluconate and triethanolamine. After determination, its solid The content is 22.8% by weight, and its molecular weight distribution is in the range of 327-683.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com