Electric magnetic-stirring high-pressure reactor

A technology of magnetic stirrer and high-pressure reactor, which is applied to chemical instruments and methods, crystal growth, mixers, etc., can solve the problems of high cost of scientific research and teaching, unfavorable operation steps, and inability to apply stirring, etc., to achieve low cost, High test efficiency and effect of preventing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

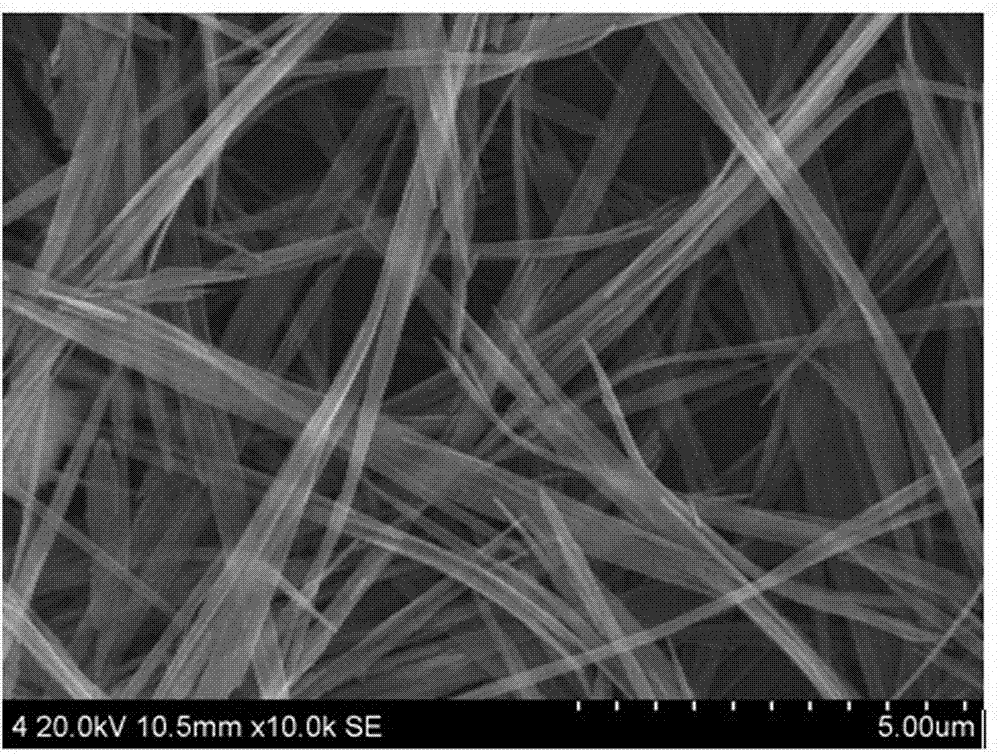

Image

Examples

Embodiment Construction

[0011] Electric magnetic stirring high-pressure reactor, including reactor body 18, heating chamber 13, magnetic stirrer motor 8, high-strength magnet 9, magnetic rotor 10, commonly used reactor (magnetic material) 11, polytetrafluoroethylene reaction tank 12, Stainless steel porous air distribution plate 14, thermocouple 15, blower fan 16, heating resistor 17, temperature setting control module 1, four magnetic stirrer motor speed setting control modules 2. A heating chamber 13 is arranged in the reactor body 18, a heating chamber door 5 is arranged on the reactor body in front of the heating chamber 13, a control panel 4 is arranged on the reactor body on one side of the heating chamber door 5, and a temperature control panel 4 is arranged on the control panel 4. Setting control module 1, four magnetic stirrer motor speed setting control modules 2, blower fan switch 3. The commonly used reactor 11 is placed on the reactor magnetic stirring table 7 in the heating chamber 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com